In predictive maintenance, various types of vibration analysis techniques are utilized to monitor the condition of machinery and equipment. Some common techniques include time waveform analysis, frequency analysis, amplitude measurement, phase analysis, envelope analysis, and modal analysis. Each technique provides valuable insights into the health and performance of industrial assets, helping to identify potential faults and issues before they escalate into costly failures.

Frequency analysis is a crucial aspect of vibration analysis techniques as it helps in identifying the different frequencies present in a machine's vibration signal. By analyzing the frequency content of the vibration data, maintenance professionals can pinpoint specific issues such as unbalance, misalignment, bearing defects, or resonance. This information allows for targeted maintenance actions to be taken to address the root cause of the problem and prevent further damage to the equipment.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Time waveform analysis in vibration analysis involves studying the raw vibration signal collected from a machine over a period of time. By analyzing the time domain data, maintenance technicians can identify patterns, trends, and anomalies in the vibration signal that may indicate potential issues with the equipment. Time waveform analysis is a fundamental technique that provides valuable insights into the overall condition of machinery and helps in diagnosing problems early on.

Amplitude measurement is a critical aspect of vibration analysis techniques as it helps in quantifying the intensity of vibrations experienced by a machine. By measuring the amplitude of vibration signals, maintenance professionals can assess the severity of a fault or issue within the equipment. This information is essential for determining the appropriate course of action to address the problem and prevent further damage or downtime.

Envelope analysis techniques play a vital role in detecting faults in rotating machinery by focusing on the modulation of vibration signals. By analyzing the envelope of the vibration signal, maintenance technicians can identify specific fault frequencies associated with issues such as gear tooth damage, bearing defects, or shaft misalignment. Envelope analysis helps in detecting faults early on and allows for timely maintenance interventions to prevent catastrophic failures.

Phase analysis is an essential tool in diagnosing vibration issues in industrial equipment as it helps in understanding the relationship between different vibration signals. By analyzing the phase relationships between various components of a machine, maintenance professionals can identify issues such as unbalance, misalignment, or resonance. Phase analysis provides valuable insights into the root cause of vibration problems and guides maintenance actions to address the underlying issues effectively.

Modal analysis is a powerful technique used in structural vibration analysis to identify the natural frequencies and mode shapes of a system. By analyzing the dynamic characteristics of a structure, maintenance engineers can determine how it will respond to different types of excitation. Modal analysis helps in understanding the behavior of a structure under various operating conditions and enables maintenance professionals to optimize the performance and reliability of industrial assets.

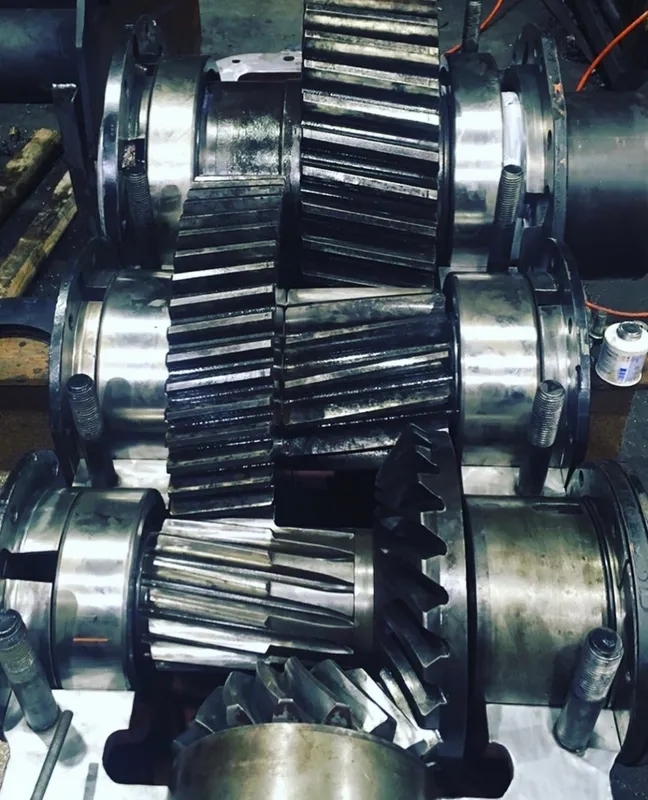

To diagnose and rectify gear tooth scoring, one must first inspect the gear teeth for any signs of wear, damage, or scoring. This can be done by visually examining the gear teeth or using specialized equipment such as a borescope or gear inspection tool. Once the scoring is identified, the root cause must be determined, which could be due to factors such as improper lubrication, misalignment, overload, or contamination. To rectify the issue, the gear teeth may need to be repaired or replaced, the lubrication system may need to be improved, the gear alignment may need to be adjusted, or the operating conditions may need to be optimized. Regular maintenance and monitoring of the gear system can help prevent future instances of gear tooth scoring.

To diagnose and repair pump discharge side erosion, the technician should first inspect the pump for any signs of erosion, such as wear on the discharge side components, corrosion, or pitting. They can use tools like borescopes or ultrasonic testing to assess the extent of the damage. Once the erosion is identified, the technician can repair it by replacing the worn components, applying protective coatings, or adjusting the pump operation to reduce erosion. It is important to address the root cause of the erosion, which could be related to fluid properties, pump design, or operating conditions, to prevent future damage. Regular maintenance and monitoring can help prevent pump discharge side erosion in the future.

When pump impellers become worn, they can often be refurbished through a process known as reconditioning or reclamation. This involves repairing any damage, restoring the impeller to its original specifications, and improving its performance. Refurbishing worn pump impellers can help extend their lifespan and save on costs compared to replacing them with new ones. However, in some cases where the impeller is severely damaged or worn beyond repair, replacement may be necessary to ensure optimal pump efficiency and functionality. It is important to consult with a professional pump technician to determine the best course of action for worn pump impellers.

Signs of misalignment in a pump shaft can include vibration, increased noise levels, overheating, premature wear on bearings, and reduced efficiency. Other indicators may include leaks, seal failures, and irregular shaft movement. It is important to regularly monitor and inspect the pump shaft for any signs of misalignment to prevent further damage and ensure optimal performance. Proper alignment of the pump shaft is crucial for maintaining the overall health and functionality of the pump system. Regular maintenance and alignment checks can help identify and address any misalignment issues before they escalate into more serious problems.

To prevent gearbox contamination from external sources, several measures can be taken. One effective method is to regularly inspect and maintain seals, gaskets, and other protective barriers to ensure they are intact and functioning properly. Additionally, implementing proper ventilation systems can help prevent the ingress of dust, dirt, and other contaminants. It is also important to keep the surrounding area clean and free of debris that could potentially enter the gearbox. Utilizing high-quality filters and breathers can further help to minimize the risk of contamination. Regularly monitoring and replacing lubricants can also play a crucial role in preventing gearbox contamination. By taking these proactive steps, the risk of external sources causing contamination in the gearbox can be significantly reduced.

Determining the appropriate pump shaft alignment tolerances involves considering factors such as shaft size, coupling type, operating speed, and alignment method. It is important to adhere to industry standards and manufacturer recommendations when setting alignment tolerances for pumps. Common alignment methods include reverse dial indicator, laser alignment, and straight edge alignment. Tolerances can vary depending on the type of pump, such as centrifugal, reciprocating, or rotary pumps. Factors like thermal growth, vibration levels, and shaft material should also be taken into account when determining alignment tolerances. Regular monitoring and adjustment of alignment tolerances can help prevent premature wear and failure of pump components.

Preventing gearbox foaming in lubricants can be achieved by implementing various measures. One effective method is to use anti-foam additives in the lubricant formulation, which help to reduce the formation of foam during operation. Additionally, ensuring that the gearbox is properly vented and that the lubricant is not overfilled can also help prevent foaming. Regularly monitoring the condition of the lubricant and changing it at recommended intervals can further prevent foaming issues. Proper maintenance of the gearbox, including checking for leaks and ensuring proper sealing, can also contribute to preventing foaming in lubricants. Overall, a combination of these measures can help maintain optimal gearbox performance and prevent foaming in lubricants.