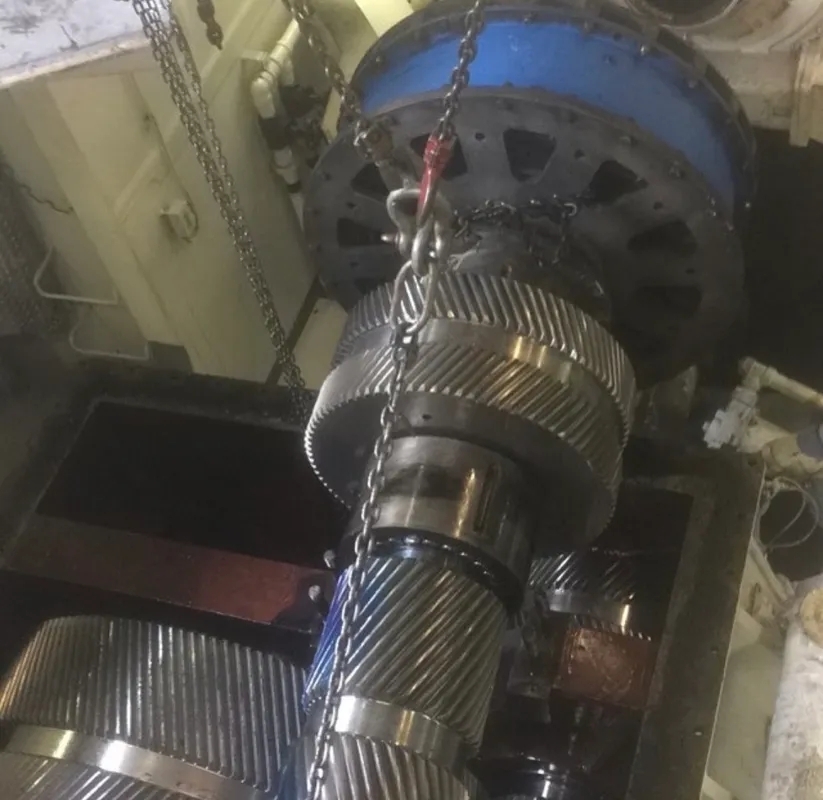

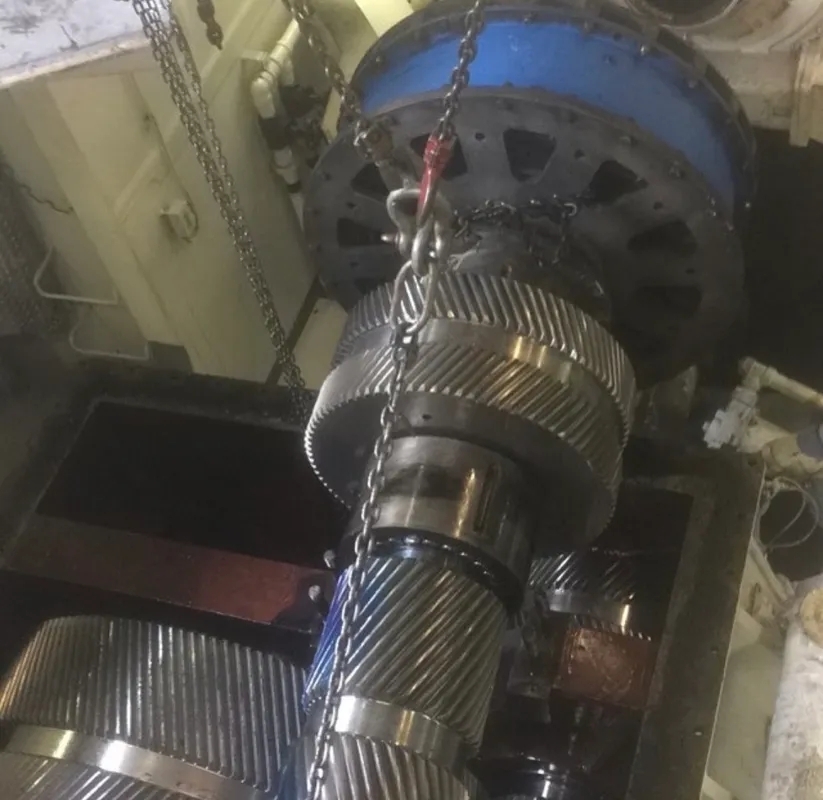

Optimizing the gear ratio in a gearbox can significantly improve efficiency by ensuring that the gears are properly matched to the desired output speed and torque requirements. By selecting the right combination of gear sizes and teeth counts, the gearbox can operate more smoothly and effectively, reducing unnecessary friction and wear. This optimization process involves careful calculations and testing to determine the most efficient gear ratio for the specific application, ultimately leading to improved overall performance.

Lubrication plays a crucial role in reducing friction and increasing efficiency in gearboxes. By applying the appropriate lubricant to the gears and bearings, the moving parts can operate more smoothly and with less resistance. This helps to minimize heat generation and wear, prolonging the lifespan of the gearbox components. Proper lubrication also helps to maintain consistent performance and reduce the risk of breakdowns or malfunctions, making it an essential aspect of gearbox maintenance and operation.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Common methods for reducing noise and vibration in gearboxes include using precision machining techniques to ensure smooth gear meshing, implementing vibration-dampening materials or coatings, and incorporating sound-absorbing components into the gearbox design. By addressing these factors, manufacturers can improve the overall performance of the gearbox and enhance the user experience by minimizing unwanted noise and vibrations during operation.

The material selection for gears can have a significant impact on the efficiency and longevity of a gearbox. Choosing high-quality materials with the right combination of strength, hardness, and wear resistance can help to reduce friction, minimize wear, and improve overall performance. Materials such as hardened steel, bronze, or composite alloys are commonly used for gears in high-performance gearboxes to ensure durability and reliability under heavy loads and harsh operating conditions.

Innovative design features can be implemented to enhance the efficiency of a gearbox, such as incorporating helical or bevel gears for smoother operation, using lightweight materials to reduce inertia and energy consumption, or integrating advanced bearing technologies for improved load distribution and reduced friction. By continuously exploring new design concepts and technologies, manufacturers can push the boundaries of gearbox performance and efficiency to meet the evolving demands of modern applications.

Regular maintenance and monitoring are essential for improving gearbox efficiency over time. By conducting routine inspections, lubrication checks, and performance evaluations, operators can identify potential issues early on and address them before they escalate into more significant problems. This proactive approach to maintenance helps to ensure that the gearbox operates at peak efficiency and extends its lifespan, ultimately reducing downtime and maintenance costs in the long run.

Advancements in technology, such as the use of computer-aided design (CAD) software for optimizing gear geometry, the development of high-performance lubricants and coatings for reducing friction, and the integration of smart sensors and monitoring systems for real-time performance tracking, are being utilized to further enhance gearbox efficiency in modern applications. By leveraging these technological innovations, manufacturers can improve the reliability, performance, and energy efficiency of gearboxes, meeting the growing demands for more sustainable and high-performing machinery in various industries.

When it comes to industrial gearbox repair, selecting the appropriate lubricant is crucial for optimal performance and longevity. Some suitable lubricants for industrial gearbox repair include synthetic oils, mineral oils, gear oils, and grease. Synthetic oils are known for their high performance in extreme temperatures and heavy-duty applications. Mineral oils are commonly used for general-purpose lubrication in industrial gearboxes. Gear oils are specifically formulated to provide protection against wear, corrosion, and oxidation in gear systems. Grease is a semi-solid lubricant that is ideal for applications where oil leakage is a concern. Overall, choosing the right lubricant for industrial gearbox repair depends on factors such as operating conditions, load capacity, and speed requirements.

To detect and repair gearbox leaks, one can start by visually inspecting the gearbox for any signs of oil stains or puddles underneath the vehicle. Using a flashlight, one can check for any visible cracks or damage to the gearbox casing. Additionally, one can perform a pressure test to identify any leaks in the gearbox seals or gaskets. To repair the leaks, one may need to replace the damaged seals or gaskets, tighten any loose bolts, or repair any cracks in the gearbox casing. It is important to use the appropriate tools and equipment to ensure a proper repair and prevent further leaks in the gearbox. Regular maintenance and inspections can help prevent gearbox leaks in the future.

One way to identify symptoms of bearing failure in a pump is to listen for any unusual noises such as grinding, squealing, or knocking sounds coming from the pump. Additionally, an increase in vibration or heat coming from the pump could indicate bearing failure. Another sign to look out for is leaking fluid around the pump, which may be caused by a damaged bearing. It is also important to check for any irregularities in the pump's performance, such as decreased flow rate or pressure. Regular maintenance and monitoring of the pump can help detect bearing failure early on and prevent further damage to the equipment.

Gearbox lubricants can be filtered and reused in some cases, depending on the level of contamination and the type of filtration system used. Filtration processes such as oil purification, centrifugal separation, and magnetic filtration can help remove contaminants like dirt, metal particles, and water from the lubricant, extending its lifespan. However, in cases of severe contamination or degradation, replacement of the lubricant may be necessary to ensure optimal gearbox performance and prevent damage. Regular monitoring of lubricant condition and implementing proper maintenance practices can help determine whether filtration and reuse are viable options for a specific gearbox system.

During gearbox repair, it is possible to straighten gearbox shafts in some cases, depending on the extent of the damage. Straightening a gearbox shaft involves using specialized tools and techniques to carefully bend the shaft back into its original shape. However, if the shaft is severely bent or damaged beyond repair, replacement may be necessary to ensure the gearbox functions properly. It is important to consult with a professional mechanic or technician to determine the best course of action for repairing gearbox shafts. Additionally, regular maintenance and inspections can help prevent shaft damage and prolong the lifespan of the gearbox.

To diagnose and repair gearbox oil oxidation issues, one must first conduct a thorough inspection of the gearbox system to identify any signs of oxidation, such as a darkening of the oil color, a burnt smell, or increased viscosity. Once oxidation is confirmed, the next step is to drain the old oil and flush the gearbox system to remove any contaminants. After cleaning the system, fresh gearbox oil with antioxidant additives should be added to prevent further oxidation. It is also important to check for any leaks or damaged seals that may be allowing air to enter the system and accelerate oxidation. Regular maintenance and monitoring of oil condition can help prevent gearbox oil oxidation issues in the future.