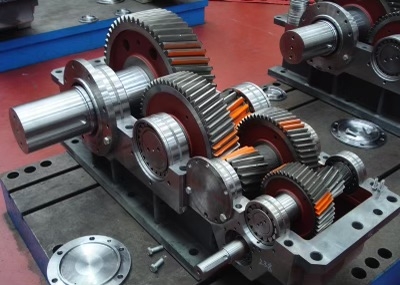

Torque in a gearbox system is calculated by multiplying the force applied to the input shaft by the distance from the center of the shaft to the point where the force is applied. This calculation takes into account the rotational force required to turn the gears within the gearbox and is essential for determining the overall performance of the system.

There are several methods used to determine the torque requirements for a gearbox. One common method is to analyze the power output needed for the application and then calculate the torque based on the gear ratio and efficiency of the gearbox. Another method involves considering the load and speed requirements of the system to determine the necessary torque for optimal performance.

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

Yes, the gear ratio can significantly affect the torque output of a gearbox. By changing the gear ratio, the mechanical advantage of the system is altered, which in turn affects the torque output. A higher gear ratio can result in increased torque at the expense of speed, while a lower gear ratio can provide higher speed but lower torque.

The efficiency of a gearbox plays a crucial role in the torque calculation process. A gearbox with high efficiency will require less input torque to achieve the desired output, while a gearbox with lower efficiency will result in higher torque requirements. It is important to consider the efficiency of the gearbox when calculating the torque needed for a specific application.

Input speed is a key factor in torque calculations for a gearbox. The speed at which the input shaft rotates directly impacts the amount of torque required to achieve the desired output. Higher input speeds may require lower torque, while lower input speeds may necessitate higher torque to maintain the desired performance levels.

There are specific formulas and equations commonly used for gearbox torque calculations. These formulas take into account factors such as gear ratio, efficiency, input speed, and load to determine the required torque for a given application. Engineers often use these calculations to design and optimize gearbox systems for maximum performance and efficiency.

Factors like friction and load can have a significant impact on the torque calculation for a gearbox. Friction within the gearbox can result in energy losses and increase the torque requirements, while the load placed on the system can also affect the amount of torque needed to overcome resistance and operate efficiently. It is important to consider these factors when calculating torque for gearbox applications to ensure optimal performance.

During gearbox repair, it is possible to straighten gearbox shafts in some cases, depending on the extent of the damage. Straightening a gearbox shaft involves using specialized tools and techniques to carefully bend the shaft back into its original shape. However, if the shaft is severely bent or damaged beyond repair, replacement may be necessary to ensure the gearbox functions properly. It is important to consult with a professional mechanic or technician to determine the best course of action for repairing gearbox shafts. Additionally, regular maintenance and inspections can help prevent shaft damage and prolong the lifespan of the gearbox.

To diagnose and repair gearbox oil oxidation issues, one must first conduct a thorough inspection of the gearbox system to identify any signs of oxidation, such as a darkening of the oil color, a burnt smell, or increased viscosity. Once oxidation is confirmed, the next step is to drain the old oil and flush the gearbox system to remove any contaminants. After cleaning the system, fresh gearbox oil with antioxidant additives should be added to prevent further oxidation. It is also important to check for any leaks or damaged seals that may be allowing air to enter the system and accelerate oxidation. Regular maintenance and monitoring of oil condition can help prevent gearbox oil oxidation issues in the future.

To diagnose and rectify gear tooth scoring, one must first inspect the gear teeth for any signs of wear, damage, or scoring. This can be done by visually examining the gear teeth or using specialized equipment such as a borescope or gear inspection tool. Once the scoring is identified, the root cause must be determined, which could be due to factors such as improper lubrication, misalignment, overload, or contamination. To rectify the issue, the gear teeth may need to be repaired or replaced, the lubrication system may need to be improved, the gear alignment may need to be adjusted, or the operating conditions may need to be optimized. Regular maintenance and monitoring of the gear system can help prevent future instances of gear tooth scoring.

To diagnose and repair pump discharge side erosion, the technician should first inspect the pump for any signs of erosion, such as wear on the discharge side components, corrosion, or pitting. They can use tools like borescopes or ultrasonic testing to assess the extent of the damage. Once the erosion is identified, the technician can repair it by replacing the worn components, applying protective coatings, or adjusting the pump operation to reduce erosion. It is important to address the root cause of the erosion, which could be related to fluid properties, pump design, or operating conditions, to prevent future damage. Regular maintenance and monitoring can help prevent pump discharge side erosion in the future.

When pump impellers become worn, they can often be refurbished through a process known as reconditioning or reclamation. This involves repairing any damage, restoring the impeller to its original specifications, and improving its performance. Refurbishing worn pump impellers can help extend their lifespan and save on costs compared to replacing them with new ones. However, in some cases where the impeller is severely damaged or worn beyond repair, replacement may be necessary to ensure optimal pump efficiency and functionality. It is important to consult with a professional pump technician to determine the best course of action for worn pump impellers.

Signs of misalignment in a pump shaft can include vibration, increased noise levels, overheating, premature wear on bearings, and reduced efficiency. Other indicators may include leaks, seal failures, and irregular shaft movement. It is important to regularly monitor and inspect the pump shaft for any signs of misalignment to prevent further damage and ensure optimal performance. Proper alignment of the pump shaft is crucial for maintaining the overall health and functionality of the pump system. Regular maintenance and alignment checks can help identify and address any misalignment issues before they escalate into more serious problems.

To prevent gearbox contamination from external sources, several measures can be taken. One effective method is to regularly inspect and maintain seals, gaskets, and other protective barriers to ensure they are intact and functioning properly. Additionally, implementing proper ventilation systems can help prevent the ingress of dust, dirt, and other contaminants. It is also important to keep the surrounding area clean and free of debris that could potentially enter the gearbox. Utilizing high-quality filters and breathers can further help to minimize the risk of contamination. Regularly monitoring and replacing lubricants can also play a crucial role in preventing gearbox contamination. By taking these proactive steps, the risk of external sources causing contamination in the gearbox can be significantly reduced.