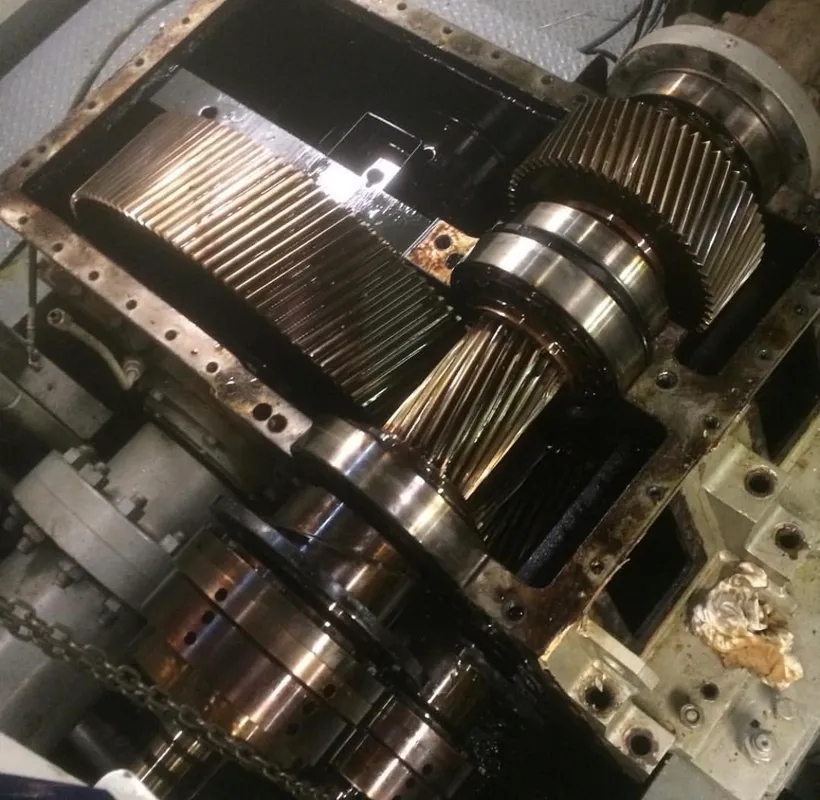

Gearbox housing cracks can be caused by a variety of factors, including excessive vibration, overloading, poor maintenance, material defects, and manufacturing flaws. These cracks can compromise the structural integrity of the gearbox housing, leading to potential equipment failure and safety hazards if not addressed promptly.

Visual inspection can be a valuable tool in detecting cracks in gearbox housings. By closely examining the surface of the housing for any signs of discoloration, deformation, or visible cracks, inspectors can identify potential areas of concern. Additionally, using techniques such as dye penetrant testing or magnetic particle inspection can help reveal hidden cracks that may not be visible to the naked eye.

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

Non-destructive testing methods such as ultrasonic testing, radiographic testing, and eddy current testing can be employed to identify cracks in gearbox housings without causing damage to the component. These techniques use sound waves, radiation, or electromagnetic fields to detect internal defects and cracks, providing valuable information about the condition of the housing.

Specific types of cracks commonly found in gearbox housings include fatigue cracks, stress corrosion cracks, and impact cracks. Fatigue cracks typically occur due to repeated loading and unloading cycles, while stress corrosion cracks result from the combined effects of stress and corrosive environments. Impact cracks, on the other hand, are caused by sudden forces or impacts on the housing.

Ultrasonic testing is a highly effective method for crack detection in gearbox housings. By sending high-frequency sound waves into the material and analyzing the reflected waves, inspectors can identify the presence, location, and size of cracks within the housing. This non-destructive technique provides detailed information about the extent of the damage without requiring disassembly of the gearbox.

The material composition of gearbox housings plays a significant role in the likelihood of cracks occurring. Materials with higher strength and toughness properties are less prone to cracking under stress or fatigue conditions. Proper selection of materials, heat treatment processes, and surface coatings can help improve the resistance of gearbox housings to cracking and prolong their service life.

To reduce the risk of cracks in gearbox housings, preventative measures such as regular maintenance, proper lubrication, monitoring of operating conditions, and implementing design improvements can be taken. Ensuring that the gearbox is not overloaded, properly aligned, and free from any defects or imperfections can help prevent the development of cracks in the housing. By implementing a proactive maintenance program and addressing any issues promptly, the risk of gearbox housing cracks can be minimized.

The most common causes of pump seal failure include improper installation, lack of proper maintenance, high operating temperatures, abrasive or corrosive fluids, excessive vibration, and inadequate lubrication. Improper installation can lead to misalignment or damage to the seal, while a lack of maintenance can result in wear and tear over time. High operating temperatures can cause the seal material to degrade, reducing its effectiveness. Abrasive or corrosive fluids can also wear down the seal prematurely. Excessive vibration can put stress on the seal, causing it to fail sooner than expected. Inadequate lubrication can lead to increased friction and heat, further contributing to seal failure. Regular inspection and maintenance can help prevent these common causes of pump seal failure.

To prevent pump seal face damage, various measures can be implemented. One effective method is to regularly inspect the pump seal for any signs of wear, corrosion, or misalignment. Proper lubrication of the seal face can also help reduce friction and prevent damage. Additionally, ensuring that the pump is operating within the recommended temperature and pressure limits can help prolong the life of the seal face. Using high-quality materials for the seal face and following manufacturer guidelines for installation and maintenance are also crucial in preventing damage. Implementing a regular maintenance schedule and promptly addressing any issues that arise can help prevent pump seal face damage in the long run.

Diagnosing and repairing pump discharge cavitation involves first identifying the symptoms such as reduced flow rate, increased noise levels, and vibration. The technician should then inspect the pump for any signs of damage or wear, including worn impeller blades, misalignment, or blockages in the discharge line. Utilizing diagnostic tools such as vibration analysis and pressure gauges can help pinpoint the exact location and severity of the cavitation. Once diagnosed, the repair process may involve adjusting the pump speed, replacing damaged components, or redesigning the system to prevent future cavitation. Proper maintenance practices, such as regular inspection and cleaning, can also help prevent pump discharge cavitation in the future.

The implications of pump impeller wear on performance can be significant, leading to decreased efficiency, reduced flow rates, increased energy consumption, and potential damage to other components of the pump system. As the impeller wears down, it may become unbalanced, causing vibrations and noise that can further impact the overall operation of the pump. Additionally, worn impellers can result in cavitation, which can lead to erosion of the impeller and other parts of the pump, ultimately reducing its lifespan. Regular maintenance and monitoring of impeller wear are essential to ensure optimal performance and prevent costly repairs or replacements in the future.

Gear tooth pitting can sometimes be repaired through processes such as grinding, honing, or shot peening. However, the extent of the damage and the specific characteristics of the gear will determine whether repair is a viable option. In some cases, replacement of the gear may be necessary if the pitting is too severe or if the structural integrity of the gear is compromised. It is important to consult with a qualified technician or engineer to assess the damage and determine the best course of action for addressing gear tooth pitting. Regular maintenance and inspection of gears can help prevent pitting and other forms of wear, prolonging the lifespan of the equipment.