Gear tooth profile wear can be accurately measured using specialized tools such as gear tooth profile gauges or optical profilometers. These tools are designed to precisely capture the dimensions and surface characteristics of gear teeth, allowing for the detection of any wear or damage. By comparing the measured profile to the ideal profile, engineers can determine the extent of wear and assess the need for maintenance or replacement.

When selecting gear tooth profile wear measurement tools, key features to look for include high precision measurement capabilities, user-friendly interfaces, compatibility with different gear types and sizes, and the ability to generate detailed reports and analysis. Additionally, tools that offer real-time monitoring and data storage capabilities can be beneficial for tracking wear progression over time.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Specific types of gear tooth profile wear that can be detected with these tools include pitting, scoring, abrasive wear, and plastic deformation. Each type of wear leaves distinct patterns on the gear tooth profile, which can be identified and quantified using specialized measurement tools. By accurately identifying the type of wear, engineers can determine the root cause and implement appropriate corrective actions.

Gear tooth profile wear measurement tools play a crucial role in predicting potential gear failures by providing early detection of wear patterns and trends. By monitoring changes in the gear tooth profile over time, engineers can anticipate potential failures before they occur, allowing for proactive maintenance and minimizing downtime. This predictive maintenance approach can significantly extend the lifespan of gears and prevent costly breakdowns.

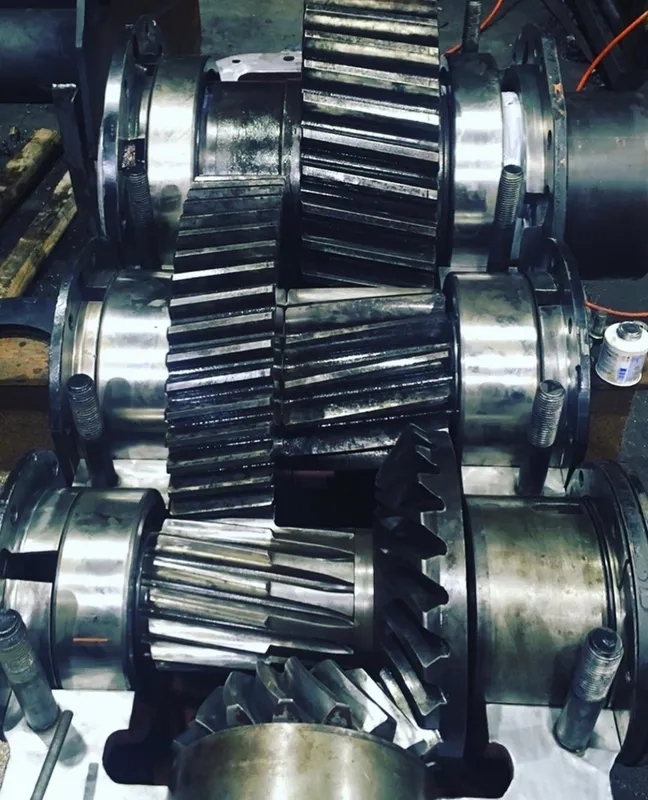

Gear tooth profile wear measurement tools can be used for different types of gears, including spur gears, helical gears, bevel gears, and worm gears. These tools are versatile and can be adapted to various gear geometries and configurations, making them suitable for a wide range of industrial applications. Whether measuring straight or angled teeth, gear tooth profile wear measurement tools provide accurate and reliable results.

Common challenges faced when using gear tooth profile wear measurement tools include calibration issues, measurement inaccuracies due to surface roughness or contamination, and difficulties in accessing hard-to-reach gear teeth. Additionally, interpreting the data collected by these tools and making informed decisions based on the results can be challenging for inexperienced users. Proper training and regular maintenance of the measurement tools are essential to overcome these challenges.

Advancements in technology have significantly improved the accuracy and efficiency of gear tooth profile wear measurement tools. For example, the integration of artificial intelligence and machine learning algorithms has enabled automated data analysis and predictive maintenance capabilities. Additionally, the development of portable and handheld measurement devices has made it easier to perform on-site inspections and monitor gear health in real-time. These technological advancements have revolutionized the field of gear diagnostics and maintenance, leading to increased reliability and cost savings for industrial operations.

When disassembling a gearbox for repair, it is important to take several precautions to ensure the process is done safely and effectively. Firstly, it is crucial to wear appropriate personal protective equipment such as gloves, goggles, and a mask to protect against any potential hazards. Additionally, the area where the disassembly is taking place should be well-ventilated to prevent the buildup of fumes or gases. It is also recommended to thoroughly clean the gearbox before beginning the disassembly process to prevent any contaminants from entering the system. Proper tools should be used to avoid damaging any components, and all parts should be carefully labeled and organized to ensure they are reassembled correctly. Finally, following manufacturer guidelines and seeking professional assistance if needed can help prevent any mistakes or accidents during the repair process.

Pump wear rings can typically be repaired through various methods such as machining, welding, or coating, depending on the extent of the damage. In some cases, replacement may be necessary if the wear rings are severely worn or damaged beyond repair. It is important to regularly inspect and maintain pump wear rings to prevent excessive wear and prolong the lifespan of the pump. Proper maintenance practices, such as monitoring clearances, lubrication, and alignment, can help prevent the need for costly repairs or replacements in the future. Additionally, consulting with a professional pump technician or engineer can provide guidance on the best course of action for repairing or replacing pump wear rings.

To prevent pump shaft bending, several measures can be taken. First, ensuring proper alignment of the pump shaft with the motor shaft is crucial. This can be achieved by using precision alignment tools and techniques. Additionally, using high-quality materials for the pump shaft, such as stainless steel or carbon steel, can help prevent bending. Regular maintenance and inspection of the pump system can also help identify any issues early on before they lead to shaft bending. Proper lubrication of the shaft bearings and ensuring that the pump is not overloaded are also important factors in preventing shaft bending. Lastly, installing vibration monitoring systems can help detect any abnormal vibrations that could indicate potential shaft bending issues.

To determine the ideal pump efficiency for a system, one must first calculate the total head, flow rate, and power consumption of the pump. By analyzing the pump curve, which shows the relationship between head and flow rate, one can identify the operating point where the pump operates most efficiently. Factors such as pump size, type, speed, and design must also be considered when determining the ideal efficiency. Additionally, conducting a pump performance test under various operating conditions can help optimize the efficiency of the pump system. Regular maintenance and monitoring of the pump performance are essential to ensure that the system continues to operate at its peak efficiency.

Gear tooth fatigue in a gearbox can be identified by signs such as pitting, spalling, cracking, and wear patterns on the gear teeth. These signs are often accompanied by increased noise, vibration, and decreased performance of the gearbox. To prevent gearbox gear tooth fatigue, proper lubrication, regular maintenance, and monitoring of operating conditions are essential. Additionally, ensuring proper gear design, material selection, and heat treatment can help prevent fatigue failure in gear teeth. Implementing proper alignment and load distribution in the gearbox can also help reduce the risk of gear tooth fatigue. Regular inspections and early detection of any signs of fatigue can help prevent catastrophic failure and prolong the life of the gearbox.

When determining the ideal gear ratio for a specific application, one must consider various factors such as the desired speed, torque requirements, power output, and efficiency. To calculate the optimal gear ratio, one can use the formula: Gear Ratio = (Output Speed / Input Speed) = (Number of Teeth on Driven Gear / Number of Teeth on Driving Gear). By taking into account the mechanical advantage needed for the system, the gear ratio can be adjusted accordingly to achieve the desired performance. Additionally, considering the gear train configuration, gear tooth profile, and material selection can also impact the overall efficiency and effectiveness of the gear system. It is essential to analyze all these factors comprehensively to determine the most suitable gear ratio for the specific application.