The wear rate of a pump impeller can be calculated based on specific operating conditions by monitoring factors such as flow rate, pressure, temperature, and the type of fluid being pumped. By analyzing these parameters over time, engineers can determine the rate at which the impeller is wearing down due to friction and erosion. This data can then be used to predict when maintenance or replacement of the impeller may be necessary to ensure optimal pump performance.

Several key factors contribute to the wear of a pump impeller over time, including the hardness and abrasiveness of the pumped fluid, the speed at which the impeller rotates, the design of the impeller itself, and the presence of any solid particles or contaminants in the fluid. These factors can cause gradual erosion or corrosion of the impeller surfaces, leading to reduced efficiency and potential damage to the pump system if not addressed promptly.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

The wear rate of a pump impeller can be predicted using mathematical models or simulations that take into account the operating conditions, material properties, and design characteristics of the impeller. By inputting data such as flow rates, pressures, and fluid properties into these models, engineers can estimate the rate of wear over time and make informed decisions about maintenance schedules and replacement intervals.

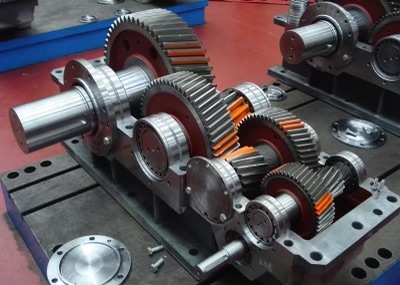

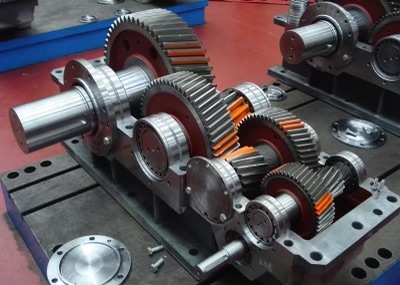

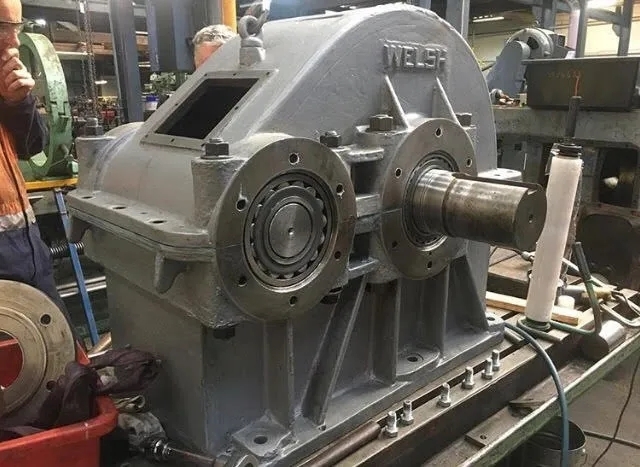

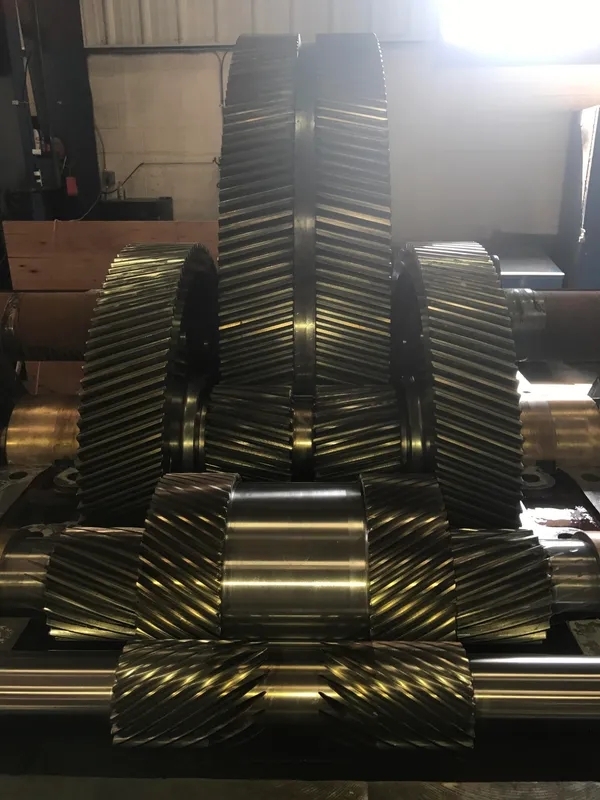

Gearbox Gearbox Lubrication System Troubleshooting Techniques

Industry standards and guidelines exist for determining the acceptable wear rate of pump impellers, typically based on factors such as the type of pump, the application, and the expected service life of the impeller. These standards help ensure that pumps operate efficiently and safely while minimizing the risk of unexpected failures due to excessive wear or damage to the impeller.

The material composition of a pump impeller can significantly affect its wear rate in different applications. For example, impellers made of materials with high hardness and corrosion resistance, such as stainless steel or ceramic, may exhibit lower wear rates when pumping abrasive or corrosive fluids compared to impellers made of softer materials like bronze or plastic. Choosing the right material for the specific application can help extend the impeller's lifespan and reduce maintenance costs.

Common methods used to monitor and assess the wear rate of pump impellers in real-time include vibration analysis, temperature monitoring, visual inspections, and wear particle analysis. By regularly monitoring these indicators, maintenance personnel can detect early signs of wear or damage to the impeller and take corrective actions to prevent further deterioration or failure of the pump system.

The wear rate of a pump impeller can be minimized through proper maintenance and operational practices, such as regular inspection and cleaning of the impeller surfaces, monitoring and adjusting operating parameters to reduce excessive wear, and using protective coatings or materials to enhance the impeller's resistance to abrasion and corrosion. By implementing a proactive maintenance strategy and following best practices, pump operators can extend the lifespan of their impellers and ensure reliable performance over time.

To detect and rectify gear tooth misalignment, one can use various methods such as visual inspection, gear tooth contact pattern analysis, and laser alignment tools. Visual inspection involves checking for any visible signs of misalignment such as uneven wear patterns or abnormal noise during operation. Gear tooth contact pattern analysis can be done by applying a special marking compound on the gear teeth and observing the contact pattern to identify any misalignment issues. Laser alignment tools can also be used to accurately measure the alignment of gear teeth and make necessary adjustments to correct any misalignment. Additionally, adjusting the gear mesh settings, checking for proper lubrication, and ensuring proper mounting and alignment of the gear components can help rectify gear tooth misalignment issues. Regular maintenance and monitoring of gear systems can also help prevent misalignment problems in the future.

Pump wear ring clearance issues can have significant implications on the overall performance and efficiency of a pump system. When there is excessive clearance between the wear ring and the impeller, it can lead to reduced pump efficiency, increased vibration, and potential damage to the pump components. This can result in higher energy consumption, decreased flow rates, and premature wear on the pump parts. Additionally, inadequate clearance can cause cavitation, which can further deteriorate the pump performance and lead to costly repairs. Proper maintenance and monitoring of wear ring clearance is essential to ensure optimal pump operation and prevent potential issues down the line.

Preventing corrosion in gearbox components can be achieved through various measures such as applying protective coatings, using corrosion-resistant materials, implementing proper lubrication practices, maintaining a clean and dry environment, conducting regular inspections for signs of corrosion, and addressing any issues promptly. Protective coatings like zinc plating, nickel plating, or powder coating can create a barrier between the component and corrosive elements. Using materials such as stainless steel, aluminum, or titanium that are inherently resistant to corrosion can also help prevent degradation. Proper lubrication with corrosion-inhibiting oils or greases can reduce friction and moisture exposure, further protecting the components. Keeping the gearbox clean and dry can prevent the buildup of corrosive agents, while regular inspections can help identify early signs of corrosion for timely intervention. By implementing these measures, gearbox components can be safeguarded against corrosion, ensuring optimal performance and longevity.

Seals in a gearbox should be replaced periodically to ensure optimal performance and prevent leaks. The frequency of seal replacement can vary depending on factors such as the type of gearbox, operating conditions, and maintenance practices. In general, it is recommended to inspect seals regularly for signs of wear or damage, and replace them as needed. Some common indicators that seals may need to be replaced include oil leaks, excessive noise or vibration, and decreased efficiency. By replacing seals in a timely manner, gearbox components can be protected from contamination and premature wear, ultimately extending the lifespan of the equipment.

To mitigate the effects of pump erosion, various measures can be implemented. One effective strategy is to regularly inspect and maintain the pump components to ensure they are in optimal condition. Utilizing erosion-resistant materials for the pump parts, such as ceramic coatings or hardened alloys, can also help prevent erosion damage. Additionally, adjusting the pump operating conditions, such as flow rate and pressure, can reduce the impact of erosion on the pump. Installing protective measures, such as erosion shields or sacrificial coatings, can further safeguard the pump from erosion. Properly sizing the pump and ensuring proper alignment and installation can also help mitigate erosion effects. Overall, a combination of preventative maintenance, material selection, operational adjustments, and protective measures can help minimize the impact of pump erosion.

Diagnosing and repairing pump suction cavitation involves first identifying the symptoms such as noise, vibration, reduced flow rate, and decreased performance. The next step is to inspect the pump for any blockages, leaks, or worn components that could be causing the cavitation. Common causes of cavitation include high suction lift, inadequate NPSH, undersized suction piping, or a clogged strainer. Once the root cause is determined, repairs may involve adjusting the pump speed, increasing the suction pipe diameter, installing a larger pump, or improving the system's NPSH. Regular maintenance and monitoring of the pump system can help prevent cavitation issues in the future.