Gearbox bearing clearance measurement tools are used to accurately measure the clearance between the gearbox bearings and the shaft. This measurement is crucial in ensuring that the bearings are properly aligned and functioning within the specified tolerances. By using these tools, technicians can identify any potential issues with the bearings, such as misalignment or excessive wear, before they lead to more serious problems within the gearbox.

Gearbox bearing clearance measurement tools play a vital role in ensuring the proper functioning of the gearbox by allowing technicians to monitor the condition of the bearings. By regularly measuring the clearance, technicians can detect any abnormalities or deviations from the manufacturer's specifications. This proactive approach helps prevent unexpected breakdowns and costly repairs by addressing any issues with the bearings before they escalate.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

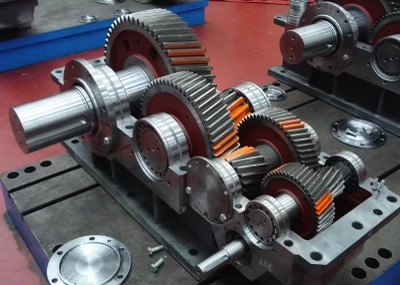

There are several types of gearbox bearing clearance measurement tools available in the market, including dial indicators, feeler gauges, and laser alignment tools. Each type of tool offers unique advantages and capabilities for measuring bearing clearance in different gearbox configurations. Technicians can choose the most suitable tool based on the specific requirements of the gearbox they are working on.

Technicians use gearbox bearing clearance measurement tools to diagnose potential issues in the gearbox by measuring the clearance between the bearings and the shaft. By comparing the measured values to the manufacturer's specifications, technicians can determine if the bearings are properly aligned and functioning within the acceptable tolerances. Any deviations from the specified clearance can indicate misalignment, wear, or other issues that may require further investigation and maintenance.

Gearbox bearing clearance measurement tools can be used for preventive maintenance of gearboxes by allowing technicians to monitor the condition of the bearings on a regular basis. By measuring the clearance at scheduled intervals, technicians can identify any changes or trends in the bearing condition and take proactive measures to address them before they lead to more serious problems. This preventive approach helps extend the lifespan of the gearbox and minimize downtime due to unexpected failures.

When using gearbox bearing clearance measurement tools, technicians should follow specific guidelines and standards to ensure accurate and reliable measurements. It is important to calibrate the tools regularly, use the correct technique for measuring the clearance, and interpret the results accurately. Following these guidelines helps technicians obtain precise measurements and make informed decisions about the condition of the gearbox bearings.

Gearbox bearing clearance measurements should be taken using these tools at regular intervals to ensure optimal gearbox performance. The frequency of measurements may vary depending on the operating conditions of the gearbox, the type of bearings used, and the manufacturer's recommendations. In general, it is recommended to measure the bearing clearance during routine maintenance checks or whenever there are signs of abnormal noise, vibration, or temperature in the gearbox. Regular monitoring of the bearing clearance helps identify potential issues early and prevent costly repairs or downtime.

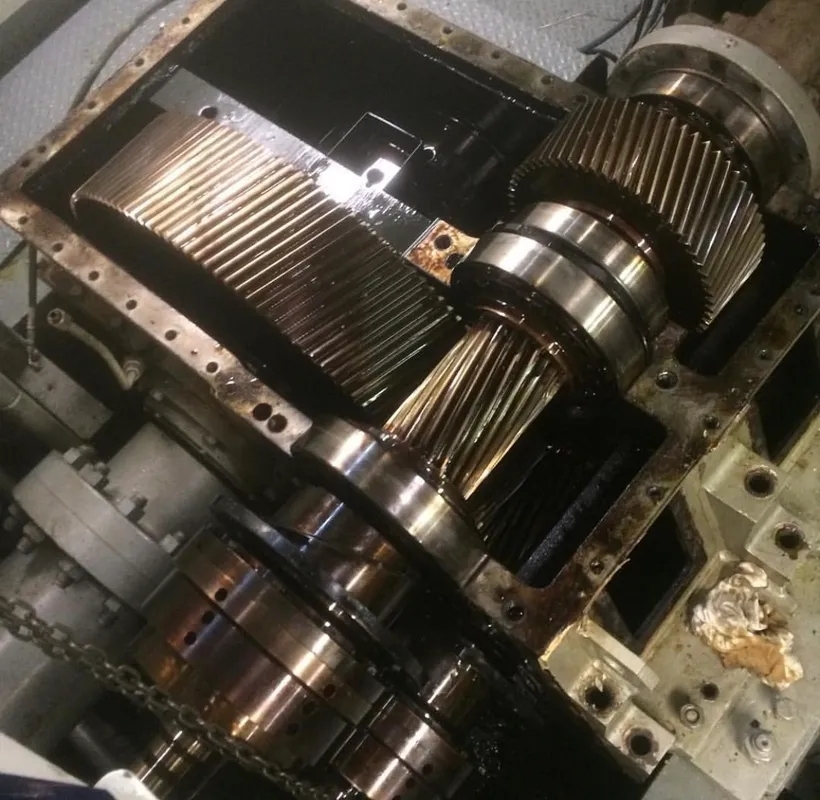

To prevent gearbox rust formation, it is important to implement proper maintenance practices such as regular cleaning, lubrication, and inspection. Using rust inhibitors or protective coatings can also help to prevent oxidation on the gearbox components. Keeping the gearbox dry and storing it in a controlled environment can further reduce the risk of rust formation. Additionally, ensuring that the gearbox is properly sealed and free from any leaks can help to prevent moisture from entering and causing corrosion. Regularly monitoring the gearbox for any signs of rust or corrosion and addressing any issues promptly can help to prolong its lifespan and prevent costly repairs.

During gearbox repair, it is possible to reharden the gears instead of replacing them. Rehardening involves heat treating the gears to restore their hardness and durability. This process can help extend the lifespan of the gears and improve their performance. However, rehardening may not always be possible depending on the extent of damage to the gears. In some cases, replacement may be necessary if the gears are too worn or damaged to be effectively rehardened. It is important to consult with a professional mechanic or gearbox specialist to determine the best course of action for repairing gearbox gears.

To prevent pump impeller cavitation, several measures can be taken. First, ensuring proper pump sizing and selection based on the specific application requirements is crucial. This includes considering factors such as flow rate, pressure, and fluid properties. Additionally, maintaining a consistent and adequate supply of fluid to the pump inlet can help prevent cavitation. Proper installation of the pump, including ensuring proper alignment and clearance, can also reduce the risk of cavitation. Regular maintenance and inspection of the pump, including checking for worn or damaged impeller blades, can help identify and address potential issues before they lead to cavitation. Using anti-cavitation devices such as inducers or pre-rotators can also help mitigate the risk of cavitation in pump impellers.

To calculate the expected gearbox seal lifespan, one must consider various factors such as the type of material used in the seal, the operating conditions of the gearbox, the level of maintenance performed on the gearbox, and the quality of the seal installation. Factors such as temperature, pressure, speed, and exposure to contaminants can all impact the lifespan of the seal. Additionally, the design of the gearbox and the amount of stress placed on the seal during operation can also play a role in determining its longevity. By analyzing these factors and conducting regular inspections and maintenance on the gearbox, one can estimate the expected lifespan of the gearbox seal. It is important to consult with industry experts and manufacturers to ensure accurate calculations and to maximize the lifespan of the gearbox seal.

To calculate the expected lifespan of pump seals, one must consider various factors such as the type of pump, operating conditions, material of the seal, maintenance practices, and environmental factors. Factors like temperature, pressure, speed, and fluid compatibility can all impact the longevity of pump seals. Regular maintenance, proper installation, and monitoring for signs of wear or damage can help extend the lifespan of pump seals. Additionally, using high-quality seals made from durable materials like carbon, ceramic, or silicon carbide can also increase their expected lifespan. By taking these factors into account and conducting regular assessments, one can estimate the expected lifespan of pump seals more accurately.

Signs of gearbox gear misalignment can include abnormal noise, vibration, overheating, and premature wear on gears and bearings. To correct gearbox gear misalignment, it is important to first identify the root cause of the issue, which could be due to improper installation, worn components, or lack of maintenance. Once the cause is determined, adjustments can be made to realign the gears properly. This may involve shimming, adjusting bearing positions, or replacing worn parts. Regular maintenance and monitoring of gearbox alignment can help prevent future misalignment issues and ensure optimal performance of the equipment.

To diagnose and repair gearbox gear tooth chipping, the technician should first conduct a thorough inspection of the gearbox to identify the extent of the damage. This may involve using specialized tools such as gear tooth calipers and magnifying lenses to closely examine the affected area. Once the chipped gear tooth has been located, the technician can then determine the best course of action for repair. This may involve grinding down the chipped area to remove any sharp edges or burrs, or in more severe cases, replacing the entire gear tooth. It is important to ensure that the repair is done with precision to maintain the proper alignment and functionality of the gearbox. Additionally, the technician should also investigate the root cause of the gear tooth chipping to prevent future occurrences, which may involve addressing issues such as improper lubrication, misalignment, or excessive loads on the gearbox.