Pump seal leakage can be caused by various factors, including wear and tear, improper installation, lack of maintenance, and exposure to corrosive or abrasive fluids. These issues can lead to gaps or cracks in the seal, allowing fluid to escape and potentially causing damage to the pump or surrounding equipment.

The type of fluid being pumped can significantly impact pump seal leakage testing procedures. Different fluids have varying levels of viscosity, acidity, and temperature, which can affect the performance and durability of the seal. It is essential to consider these factors when conducting leakage tests to ensure the seal can withstand the specific fluid properties.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

The pump seal material plays a crucial role in preventing leakage. The material must be compatible with the fluid being pumped and resistant to wear, corrosion, and high temperatures. Choosing the right seal material can help maintain a tight seal and prevent leaks, extending the lifespan of the pump and reducing maintenance costs.

Temperature and pressure fluctuations can have a significant impact on pump seal leakage. Extreme temperatures can cause the seal material to expand or contract, leading to gaps or cracks that allow fluid to escape. Similarly, fluctuations in pressure can put additional stress on the seal, increasing the risk of leakage over time.

Recommended maintenance practices to prevent pump seal leakage include regular inspection, lubrication, and replacement of worn seals. It is essential to monitor the condition of the seal, address any issues promptly, and follow manufacturer guidelines for maintenance and replacement intervals. Proper maintenance can help extend the life of the seal and prevent costly leaks.

Vibration analysis can be used to detect potential pump seal leakage issues. Excessive vibration can indicate misalignment, wear, or damage to the seal, which may lead to leakage. By monitoring vibration levels and conducting regular inspections, maintenance personnel can identify and address seal issues before they escalate into more significant problems.

Ignoring pump seal leakage issues in industrial settings can have severe consequences, including equipment damage, production downtime, safety hazards, and environmental contamination. Leaks can lead to costly repairs, reduced efficiency, and potential regulatory fines. It is crucial to address seal leakage promptly to ensure the reliability and safety of the pumping system.

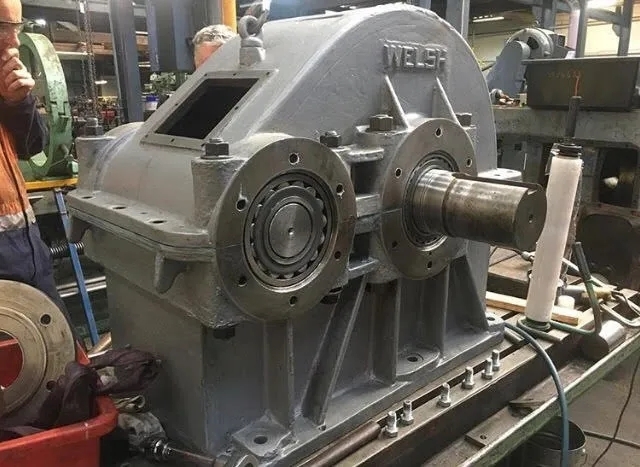

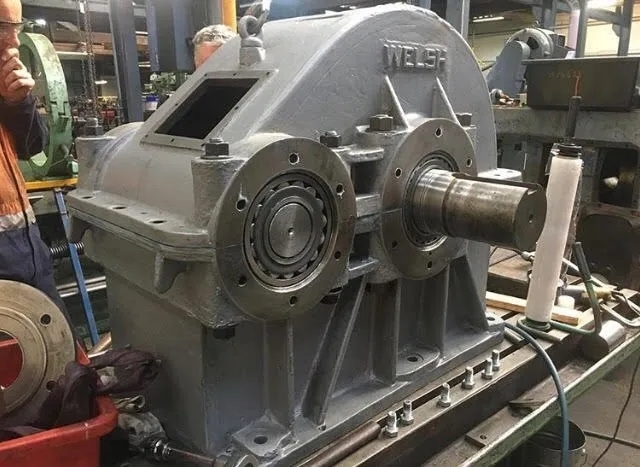

To identify and rectify gearbox oil leakage, one should first inspect the gearbox casing, seals, gaskets, and connections for any signs of oil seepage or dripping. Common indicators of a gearbox oil leak include oil spots or puddles underneath the vehicle, a burning smell coming from the engine bay, or low oil levels in the gearbox. Once the source of the leak is identified, the affected seals, gaskets, or connections should be replaced or repaired accordingly. It is important to use the correct type of gearbox oil and ensure that all components are properly tightened to prevent future leaks. Regular maintenance and inspections can help prevent gearbox oil leakage and ensure optimal performance of the vehicle.

To identify and repair pump seal face erosion, one must first inspect the pump seal face for signs of erosion, such as pitting, grooving, or uneven wear. This can be done using visual inspection or by measuring the surface roughness of the seal face. Once erosion is identified, the next step is to determine the root cause, which could be due to abrasive particles in the fluid, improper lubrication, or excessive operating temperatures. To repair the erosion, the seal face may need to be polished or resurfaced using specialized equipment and techniques. Additionally, addressing the underlying cause of the erosion is crucial to prevent future damage and ensure the longevity of the pump seal.

During the repair of pump impellers, it is possible to balance them to ensure optimal performance. This process involves identifying any areas of imbalance and making adjustments to correct them. Balancing can help prevent issues such as vibration, noise, and premature wear. However, in some cases where the impeller is severely damaged or worn, replacement may be necessary to restore the pump to its original efficiency. It is important to consult with a professional technician to determine the best course of action for repairing or replacing pump impellers.

Diagnosing and repairing gearbox oil foaming issues involves first identifying the potential causes of the problem, such as excessive heat, overfilling of the gearbox, or the presence of contaminants in the oil. To diagnose the issue, a mechanic may need to inspect the gearbox for signs of foaming, check the oil level and quality, and assess the operating conditions of the equipment. Once the cause of the foaming is determined, the mechanic can then take appropriate steps to repair the issue, such as draining and replacing the oil, adjusting the oil level, or installing a foam suppressant additive. Regular maintenance and monitoring of the gearbox can help prevent foaming issues from occurring in the future.

Typical symptoms of pump impeller wear may include decreased flow rate, reduced efficiency, increased vibration, cavitation, and noise. As the impeller wears down, it may become unbalanced, leading to vibrations and noise during operation. Additionally, the reduced efficiency can result in decreased flow rate and increased energy consumption. Cavitation, caused by the formation and collapse of vapor bubbles due to low pressure areas around the impeller, can also occur as a result of wear. Overall, monitoring for these symptoms can help identify impeller wear and prevent further damage to the pump system.