The design of the gearbox cooling system plays a crucial role in the overall performance of a vehicle. Efficient cooling helps prevent overheating of the gearbox, which can lead to premature wear and damage to components. A well-designed cooling system ensures that the gearbox operates within the optimal temperature range, allowing for smoother gear shifts and improved overall performance.

Key components of a gearbox cooling system design include a radiator, a cooling fan, transmission fluid cooler, and various hoses and connectors. The radiator helps dissipate heat from the transmission fluid, while the cooling fan regulates airflow to maintain the desired temperature. The transmission fluid cooler helps further reduce the temperature of the fluid, ensuring optimal performance and longevity of the gearbox.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Engineers determine the optimal cooling capacity needed for a specific gearbox application by considering factors such as the power output of the engine, the weight of the vehicle, and the intended use of the vehicle. By conducting thermal analysis and simulations, engineers can calculate the heat generated by the gearbox and design a cooling system that can effectively dissipate this heat to prevent overheating.

Thermal management plays a critical role in the design of a gearbox cooling system as it ensures that the gearbox operates at the right temperature. Proper thermal management helps maintain the viscosity of the transmission fluid, which is essential for smooth gear shifts and overall performance. By carefully designing the cooling system to manage heat effectively, engineers can optimize the performance and durability of the gearbox.

Advancements in materials technology have a significant influence on the design of gearbox cooling systems. The use of lightweight and heat-resistant materials allows for the construction of more efficient cooling components that can withstand high temperatures and harsh operating conditions. By incorporating advanced materials into the design, engineers can improve the overall efficiency and reliability of gearbox cooling systems.

When designing a gearbox cooling system for high-performance vehicles, engineers often face challenges such as limited space for cooling components, increased heat generation from high-power engines, and the need for enhanced thermal dissipation capabilities. Balancing these factors while ensuring optimal performance and reliability can be a complex task, requiring careful consideration of various design parameters and trade-offs.

The integration of electronic cooling systems can have a significant impact on the overall efficiency of a gearbox cooling system design. By incorporating electronic controls and sensors, engineers can monitor and adjust the cooling system in real-time to respond to changing operating conditions. This level of control allows for more precise temperature regulation and improved performance, ultimately enhancing the overall efficiency and reliability of the gearbox cooling system.

Common causes of pump vibration can include unbalanced rotating components, misalignment of pump shafts, worn bearings, cavitation, and excessive fluid flow rates. These issues can be addressed by conducting regular maintenance to ensure proper balance and alignment of rotating parts, replacing worn bearings, adjusting fluid flow rates to optimal levels, and addressing any cavitation issues through proper pump design or installation modifications. Additionally, using vibration monitoring systems can help detect and address any potential vibration issues before they escalate. Proper installation and maintenance procedures are essential in preventing and addressing pump vibration problems.

Pump impeller imbalance can have several implications on the overall performance and efficiency of a pumping system. When the impeller is not properly balanced, it can lead to increased vibration, noise, and wear on the pump components. This imbalance can also result in reduced flow rates, decreased energy efficiency, and potential damage to the pump shaft and bearings. Additionally, an imbalanced impeller can cause cavitation, which can further deteriorate the pump performance and lead to costly repairs. It is crucial to address pump impeller imbalance promptly to prevent these negative consequences and ensure the smooth operation of the pumping system. Regular maintenance and monitoring of the impeller balance are essential to avoid any potential issues.

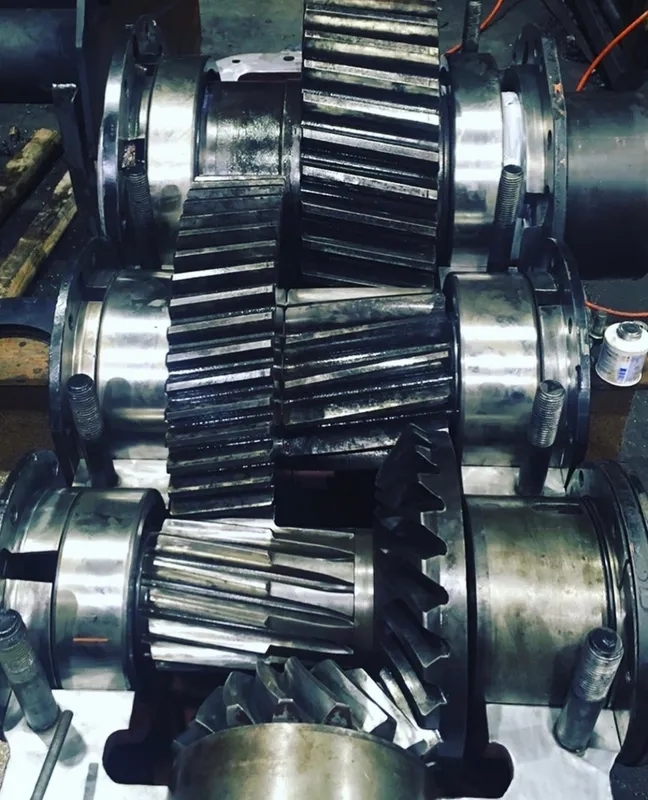

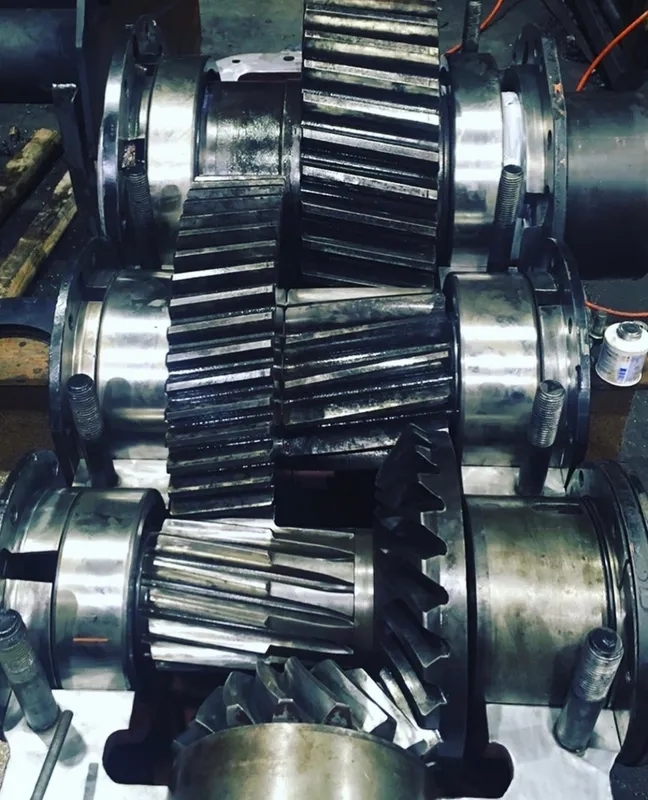

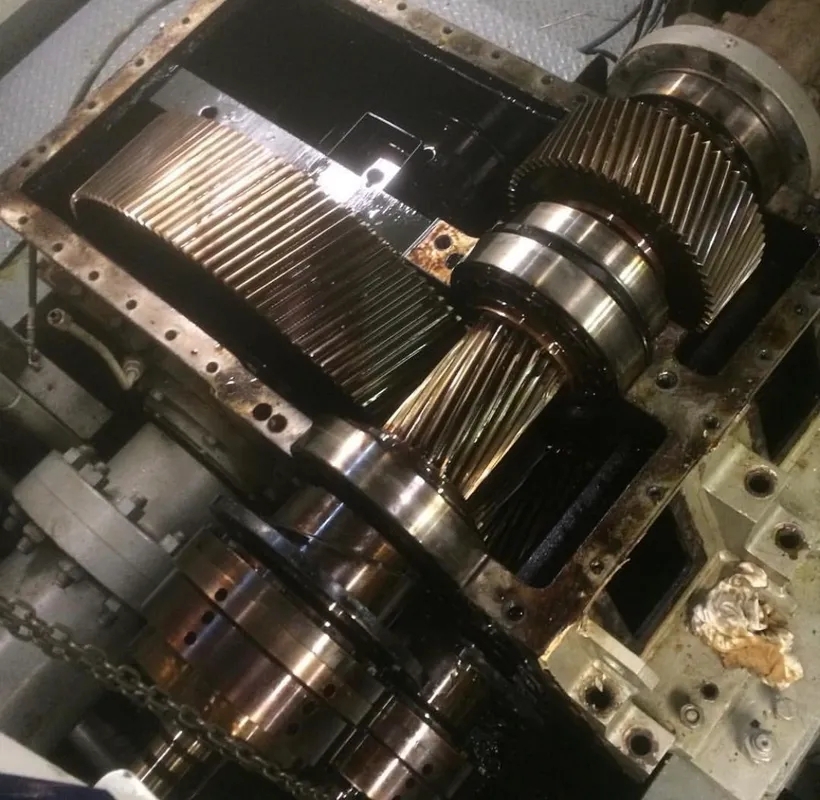

Helical gears and spur gears are two common types of gears used in gearboxes, each with its own unique characteristics. Helical gears have teeth that are cut at an angle to the gear axis, resulting in a smoother and quieter operation compared to spur gears, which have straight teeth that are parallel to the gear axis. The helical gears also have a larger contact area, which allows for higher torque transmission and better load distribution. However, helical gears tend to produce axial thrust, requiring additional bearings to support the shaft. On the other hand, spur gears are simpler in design and easier to manufacture, making them more cost-effective. They are also more efficient in terms of power transmission due to less sliding friction. Overall, the choice between helical and spur gears in gearboxes depends on factors such as noise level, load capacity, efficiency, and cost.

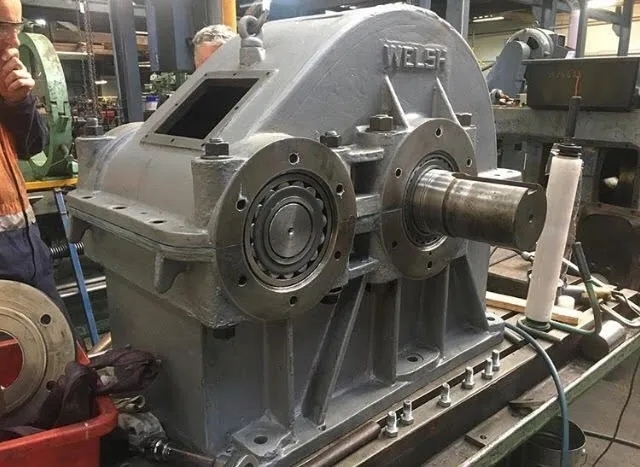

When deciding between repairing or replacing gearbox components, it is important to consider factors such as the extent of damage, cost of repairs, availability of replacement parts, and overall performance of the gearbox. If the damage is minor and can be easily fixed with a simple repair, it may be more cost-effective to opt for repairing the components. However, if the damage is extensive and the cost of repairs is close to or exceeds the cost of replacement parts, it may be more practical to replace the components altogether. Additionally, if the gearbox is older and showing signs of wear and tear, replacing the components may improve overall performance and longevity. Ultimately, the decision should be based on a thorough assessment of the situation and weighing the pros and cons of each option.

During gear repair, it is possible to reprofile gear teeth instead of replacing them entirely. This process involves reshaping the teeth to restore their proper form and function. By using specialized tools and equipment, technicians can adjust the profile of the teeth to ensure proper meshing and alignment within the gear system. Reprofiling gear teeth can help extend the lifespan of the gear and prevent the need for costly replacements. However, it is important to consult with a professional to determine the best course of action for repairing damaged gear teeth.