The flow rate of a pump can be accurately calibrated by using a flow meter to measure the actual flow rate of the pump and comparing it to the expected flow rate. Adjustments can then be made to the pump settings to ensure that the flow rate matches the desired specifications.

The key steps involved in calibrating the flow rate of a pump include setting up the necessary equipment, such as a flow meter and pressure gauge, running the pump at different flow rates, recording the data, analyzing the results, and making any necessary adjustments to the pump settings.

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

Equipment typically used in pump flow rate calibration procedures includes flow meters, pressure gauges, calibration weights, and calibration software. These tools help accurately measure the flow rate of the pump and ensure that it is operating within the desired parameters.

Specific standards and guidelines, such as those set by organizations like the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO), need to be followed during pump flow rate calibration to ensure accuracy and consistency. Adhering to these standards helps maintain the quality and reliability of the calibration process.

Pump flow rate calibration should be performed regularly to ensure accuracy and efficiency in the pump's operation. It is recommended to calibrate the flow rate of a pump at least once a year, or more frequently if the pump is used in critical applications where precise flow control is essential.

The potential consequences of not calibrating the flow rate of a pump regularly include inaccurate flow measurements, reduced efficiency, increased energy consumption, and potential damage to the pump or other system components. Regular calibration helps prevent these issues and ensures optimal performance.

Calibration procedures may vary slightly for different types of pumps, such as centrifugal pumps versus positive displacement pumps, due to their unique operating principles and characteristics. However, the basic steps involved in pump flow rate calibration remain the same, focusing on accurately measuring and adjusting the flow rate to meet the required specifications for each type of pump.

To mitigate the effects of pump erosion, various measures can be implemented. One effective strategy is to regularly inspect and maintain the pump components to ensure they are in optimal condition. Utilizing erosion-resistant materials for the pump parts, such as ceramic coatings or hardened alloys, can also help prevent erosion damage. Additionally, adjusting the pump operating conditions, such as flow rate and pressure, can reduce the impact of erosion on the pump. Installing protective measures, such as erosion shields or sacrificial coatings, can further safeguard the pump from erosion. Properly sizing the pump and ensuring proper alignment and installation can also help mitigate erosion effects. Overall, a combination of preventative maintenance, material selection, operational adjustments, and protective measures can help minimize the impact of pump erosion.

Diagnosing and repairing pump suction cavitation involves first identifying the symptoms such as noise, vibration, reduced flow rate, and decreased performance. The next step is to inspect the pump for any blockages, leaks, or worn components that could be causing the cavitation. Common causes of cavitation include high suction lift, inadequate NPSH, undersized suction piping, or a clogged strainer. Once the root cause is determined, repairs may involve adjusting the pump speed, increasing the suction pipe diameter, installing a larger pump, or improving the system's NPSH. Regular maintenance and monitoring of the pump system can help prevent cavitation issues in the future.

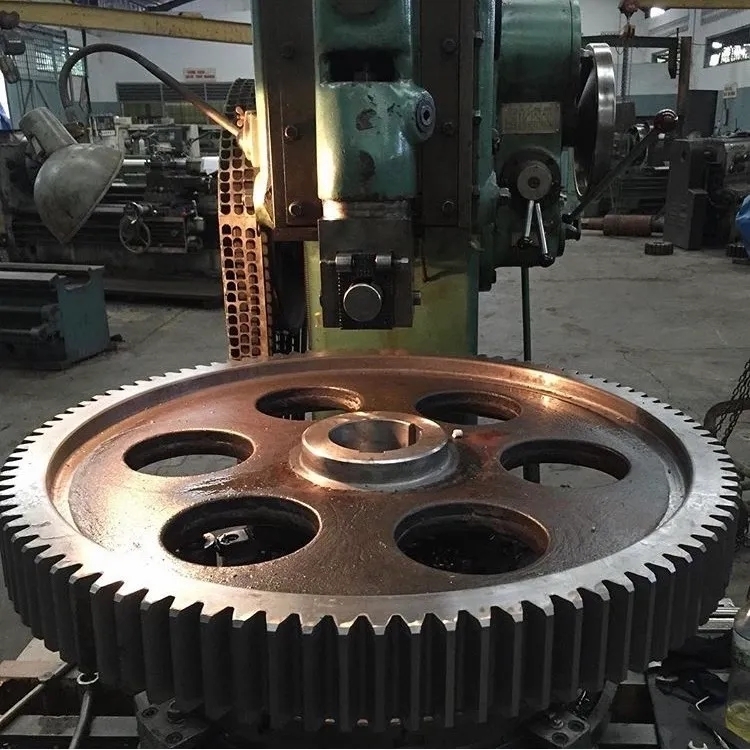

To identify and repair pump suction side erosion, one must first inspect the pump components for signs of wear, such as pitting, corrosion, or rough surfaces. Common causes of erosion on the suction side of a pump include cavitation, abrasive particles in the fluid, and high flow velocities. To repair the erosion, one can use methods such as applying protective coatings, replacing worn components, or adjusting the pump operation to reduce erosion. It is important to address suction side erosion promptly to prevent further damage to the pump and ensure optimal performance. Regular maintenance and monitoring of the pump system can help prevent erosion issues in the future.

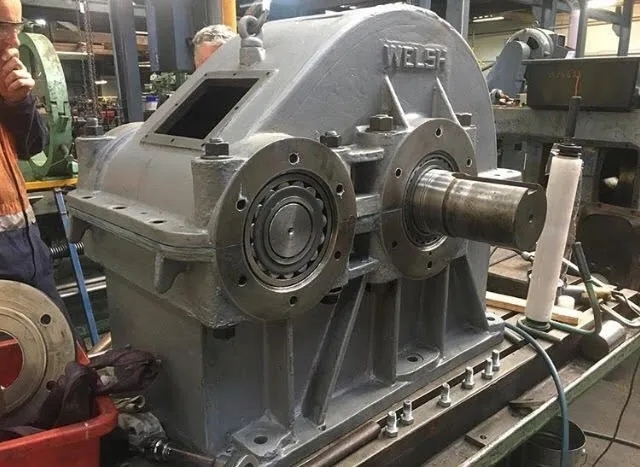

Gearbox bearing failure can be identified by several key signs, including unusual noises such as grinding, whining, or rumbling coming from the transmission. Other indicators may include difficulty shifting gears, vibrations felt through the gear stick or floorboard, and leaks of transmission fluid. In some cases, there may also be a burning smell or visible metal shavings in the transmission fluid. It is important to address these symptoms promptly, as gearbox bearing failure can lead to more extensive damage to the transmission if left untreated. Regular maintenance and inspections can help prevent gearbox bearing failure and ensure the longevity of the transmission system.

To calculate the expected pump bearing lifespan, one must consider various factors such as the type of bearing used, the load and speed at which the pump operates, the lubrication system in place, and the environmental conditions in which the pump is located. By analyzing these factors and consulting manufacturer specifications, engineers can estimate the expected lifespan of the pump bearing. Additionally, conducting regular maintenance and monitoring the condition of the bearing can help prolong its lifespan and prevent unexpected failures. It is important to consider all these factors in order to accurately predict the expected lifespan of a pump bearing.