The recommended lubrication intervals for pump motor bearings typically depend on factors such as the operating conditions, speed, and load of the pump. In general, it is advisable to lubricate pump motor bearings every 3 to 6 months to ensure optimal performance and longevity. Regular lubrication helps reduce friction, wear, and heat generation, ultimately extending the lifespan of the bearings.

Over-lubrication of pump motor bearings can have a detrimental impact on their performance. Excessive lubricant can lead to increased operating temperatures, which can cause the lubricant to break down and lose its effectiveness. This can result in accelerated wear and premature failure of the bearings. It is crucial to follow manufacturer recommendations and guidelines to avoid over-lubrication and maintain the proper functioning of the pump motor bearings.

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

When it comes to high-speed pump motor bearings, it is essential to use a lubricant that is specifically designed for such applications. Synthetic oils or greases with high viscosity and excellent thermal stability are typically recommended for high-speed bearings. These lubricants can withstand the demanding conditions of high-speed operation and provide adequate protection against friction and wear.

Temperature requirements for lubricating pump motor bearings can vary depending on the type of lubricant being used and the operating conditions of the pump. In general, it is important to ensure that the lubricant remains within the recommended temperature range to maintain its viscosity and lubricating properties. Extreme temperatures can cause the lubricant to degrade or solidify, leading to inadequate lubrication and potential damage to the bearings.

To determine if pump motor bearings need to be re-lubricated, one can perform regular inspections and monitoring of the bearings. Signs that indicate the need for re-lubrication include increased noise, vibration, or operating temperatures, as well as visible wear or damage to the bearings. It is essential to establish a maintenance schedule and follow manufacturer guidelines to ensure timely re-lubrication and prevent potential issues with the pump motor bearings.

The consequences of using the wrong type of lubricant on pump motor bearings can be severe. Incompatible lubricants can lead to poor lubrication, increased friction, and accelerated wear of the bearings. Using the wrong lubricant can also cause chemical reactions, contamination, or corrosion, further compromising the performance and lifespan of the bearings. It is crucial to select the appropriate lubricant based on the operating conditions and requirements of the pump motor bearings.

Purging old lubricant from pump motor bearings before re-lubricating is a critical step in the maintenance process. This involves removing any residual or contaminated lubricant from the bearings to ensure proper lubrication and prevent issues such as cross-contamination or reduced lubricant effectiveness. The purging process typically involves cleaning the bearings, applying a solvent or flushing agent to remove old lubricant, and allowing the bearings to dry before reapplying fresh lubricant. Following a thorough purging procedure helps optimize the performance and longevity of pump motor bearings.

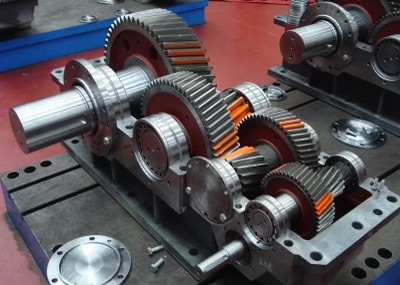

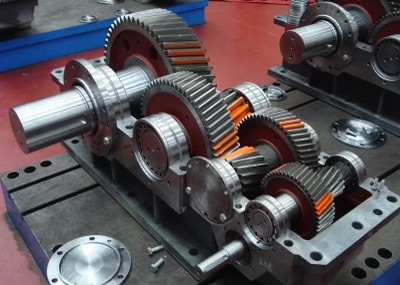

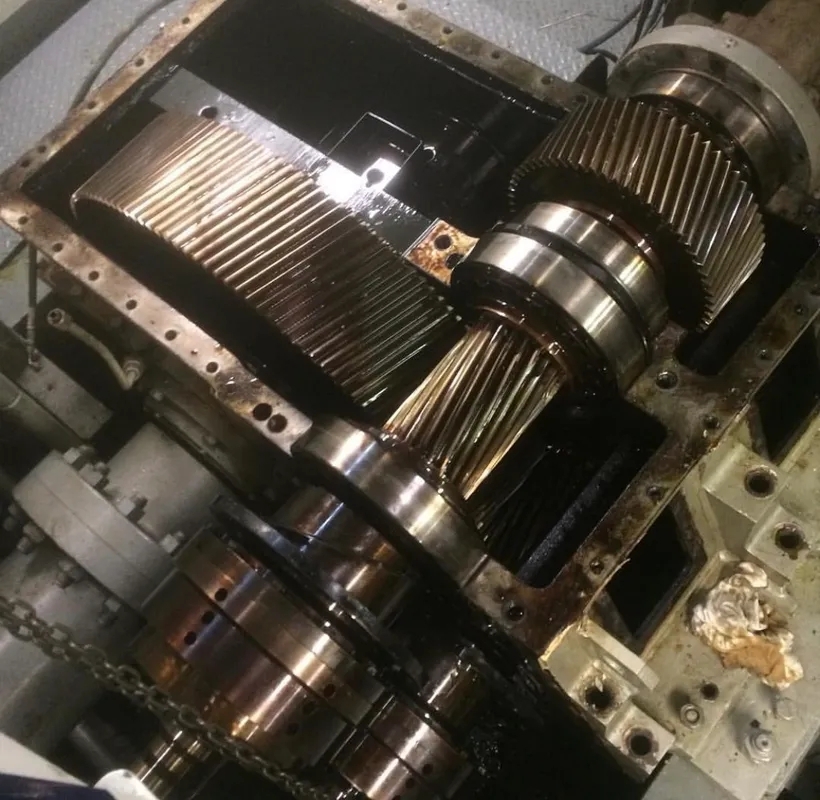

Identifying and repairing gearbox gear mesh issues involves conducting a thorough inspection of the gears, teeth, and overall gear assembly. Common signs of gear mesh issues include abnormal noise, vibration, and difficulty shifting gears. To identify the specific problem, technicians may use tools such as gear mesh analyzers, gear tooth contact pattern testers, and vibration analysis equipment. Once the issue is identified, repairs may involve adjusting gear clearances, replacing worn or damaged gears, lubricating the gears properly, or realigning the gear assembly. It is important to follow manufacturer guidelines and specifications when repairing gearbox gear mesh issues to ensure optimal performance and longevity of the gearbox.

Determining the root cause of pump bearing failure involves a thorough analysis of various factors such as lubrication issues, misalignment, overloading, contamination, and inadequate maintenance practices. By conducting vibration analysis, thermography, oil analysis, and visual inspections, engineers can pinpoint the specific reason behind the bearing failure. Additionally, considering factors like bearing material, operating conditions, and environmental factors can provide valuable insights into the root cause of the failure. By utilizing advanced diagnostic tools and techniques, engineers can accurately identify the underlying issues leading to pump bearing failure and implement corrective measures to prevent future occurrences.

Determining the appropriate pump bearing clearance involves considering factors such as shaft size, operating temperature, lubrication type, and pump speed. The clearance between the bearing and the shaft is crucial for ensuring proper alignment and reducing friction. It is important to follow manufacturer guidelines and specifications to determine the correct clearance for optimal pump performance. Factors such as thermal expansion, material compatibility, and load distribution should also be taken into account when selecting the appropriate bearing clearance. Regular maintenance and monitoring of the bearing clearance is essential to prevent premature wear and failure of the pump system.

When determining the appropriate gearbox alignment tolerances, it is important to consider factors such as shaft misalignment, parallelism, angularity, and offset. The alignment tolerances can vary depending on the type of gearbox, the speed and load requirements, and the specific application. It is crucial to follow the manufacturer's guidelines and specifications to ensure optimal performance and longevity of the gearbox. Utilizing precision alignment tools such as laser alignment systems can help in achieving the desired tolerances. Regular monitoring and adjustment of the gearbox alignment can prevent premature wear and damage, ultimately improving the overall efficiency and reliability of the system.

When repairing planetary gearboxes, there are several specific considerations that must be taken into account. These include checking for any signs of wear or damage on the gears, bearings, and shafts, as well as ensuring proper alignment of the gears within the gearbox. It is important to use high-quality replacement parts and lubricants to ensure optimal performance and longevity of the gearbox. Additionally, proper torque specifications must be followed during reassembly to prevent any issues with gear meshing or alignment. Regular maintenance and inspections are also recommended to prevent any future issues with the gearbox. Overall, attention to detail and following manufacturer guidelines are crucial when repairing planetary gearboxes.

The main causes of pump seal leaks can be attributed to factors such as wear and tear, improper installation, lack of maintenance, high pressure, and corrosive fluids. These issues can lead to seal degradation, cracks, or misalignment, resulting in leaks. To fix pump seal leaks, one can consider replacing the seal with a new one, ensuring proper installation techniques are followed, conducting regular maintenance checks, adjusting pressure levels, and using compatible fluids to prevent corrosion. Additionally, utilizing seal support systems or upgrading to more durable seal materials can also help prevent future leaks.

When disassembling a gearbox for repair, it is important to take several precautions to ensure the process is done safely and effectively. Firstly, it is crucial to wear appropriate personal protective equipment such as gloves, goggles, and a mask to protect against any potential hazards. Additionally, the area where the disassembly is taking place should be well-ventilated to prevent the buildup of fumes or gases. It is also recommended to thoroughly clean the gearbox before beginning the disassembly process to prevent any contaminants from entering the system. Proper tools should be used to avoid damaging any components, and all parts should be carefully labeled and organized to ensure they are reassembled correctly. Finally, following manufacturer guidelines and seeking professional assistance if needed can help prevent any mistakes or accidents during the repair process.