Signs that indicate a pump casing wear ring needs replacement include increased vibration and noise during operation, reduced pump efficiency, and visible wear marks on the ring itself. If the wear ring is not replaced promptly, it can lead to further damage to the pump components and a decrease in overall performance.

Pump casing wear rings should be inspected for wear and tear on a regular basis, ideally during routine maintenance checks. Depending on the operating conditions and the type of pump, it is recommended to inspect the wear rings every 6 to 12 months to ensure they are in good condition and functioning properly.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Common materials used for pump casing wear rings include bronze, stainless steel, and various types of composite materials. The choice of material depends on factors such as the type of fluid being pumped, operating temperature, and the level of abrasion resistance required for the specific application.

In most cases, pump casing wear rings cannot be effectively repaired and should be replaced when signs of wear are detected. Attempting to repair a worn wear ring may compromise the integrity of the pump and lead to further issues down the line. It is best to replace the wear ring with a new one to ensure optimal pump performance.

When installing a new pump casing wear ring, it is important to follow specific guidelines to ensure proper fit and function. This includes ensuring the ring is installed in the correct orientation, using the appropriate tools and techniques for installation, and checking for any leaks or misalignments once the ring is in place.

The wear ring plays a crucial role in the performance and efficiency of a pump by reducing internal recirculation and maintaining clearances between the impeller and the casing. A worn wear ring can lead to increased internal leakage, reduced pump efficiency, and potential damage to other pump components.

Failing to replace a worn pump casing wear ring in a timely manner can result in a range of consequences, including decreased pump efficiency, increased energy consumption, and potential damage to the impeller and casing. Ignoring signs of wear on the wear ring can lead to more extensive and costly repairs in the future, making regular inspection and replacement essential for maintaining optimal pump performance.

Pump cavitation damage can sometimes be reversed through repair, depending on the extent of the damage and the specific components affected. In some cases, repair techniques such as welding, re-machining, or coating may be able to restore the pump to full functionality. However, in more severe cases where the damage is extensive or irreparable, replacement of the damaged components or the entire pump may be necessary. It is important to assess the damage carefully and consult with a professional to determine the best course of action for addressing pump cavitation damage.

Pump cavitation can indeed result in damage to other system components due to the formation of vapor bubbles collapsing within the pump. This phenomenon can cause erosion, pitting, and surface fatigue on nearby components such as impellers, casings, and bearings. The implosion of these vapor bubbles generates high-pressure shock waves that can weaken the material of the components, leading to cracks and ultimately failure. Additionally, the turbulent flow created by cavitation can result in increased vibration levels, further contributing to the degradation of surrounding system elements. Therefore, it is crucial to address pump cavitation promptly to prevent extensive damage to other system components.

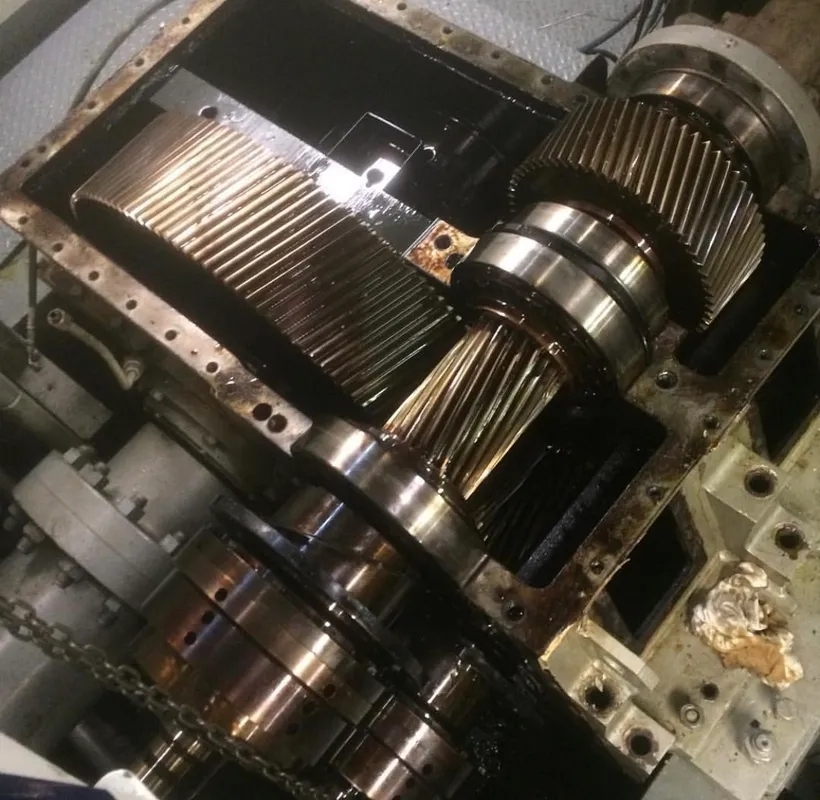

When troubleshooting excessive vibration in a gearbox, it is important to first check for any misalignment, unbalance, or wear in the gears, bearings, or shafts. Inspecting the lubrication system for proper oil levels and quality is also crucial, as inadequate lubrication can lead to increased friction and vibration. Additionally, examining the gearbox housing for any cracks or damage that may be affecting its stability is recommended. Performing vibration analysis using specialized equipment can help pinpoint the source of the excessive vibration and determine the necessary corrective actions. Regular maintenance and monitoring of the gearbox can help prevent issues that may lead to excessive vibration in the future.

Viscosity plays a crucial role in pump performance as it directly affects the flow rate and efficiency of the pump. The viscosity of a fluid determines how easily it can flow through the pump system, with higher viscosity fluids requiring more energy to pump. Adjusting the viscosity of a fluid can be done by changing its temperature, adding viscosity modifiers, or using different types of pumps designed for specific viscosity ranges. By optimizing the viscosity of the fluid being pumped, the pump performance can be improved, leading to increased efficiency and reduced energy consumption. Proper viscosity management is essential in ensuring the smooth operation of pumps in various industrial applications.

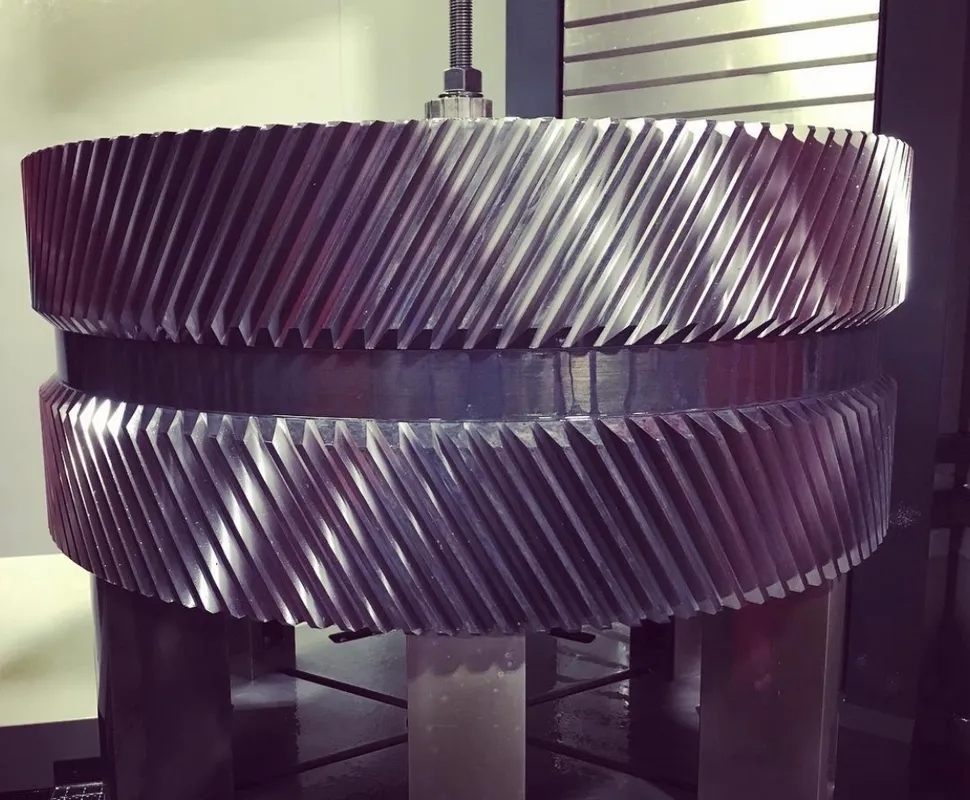

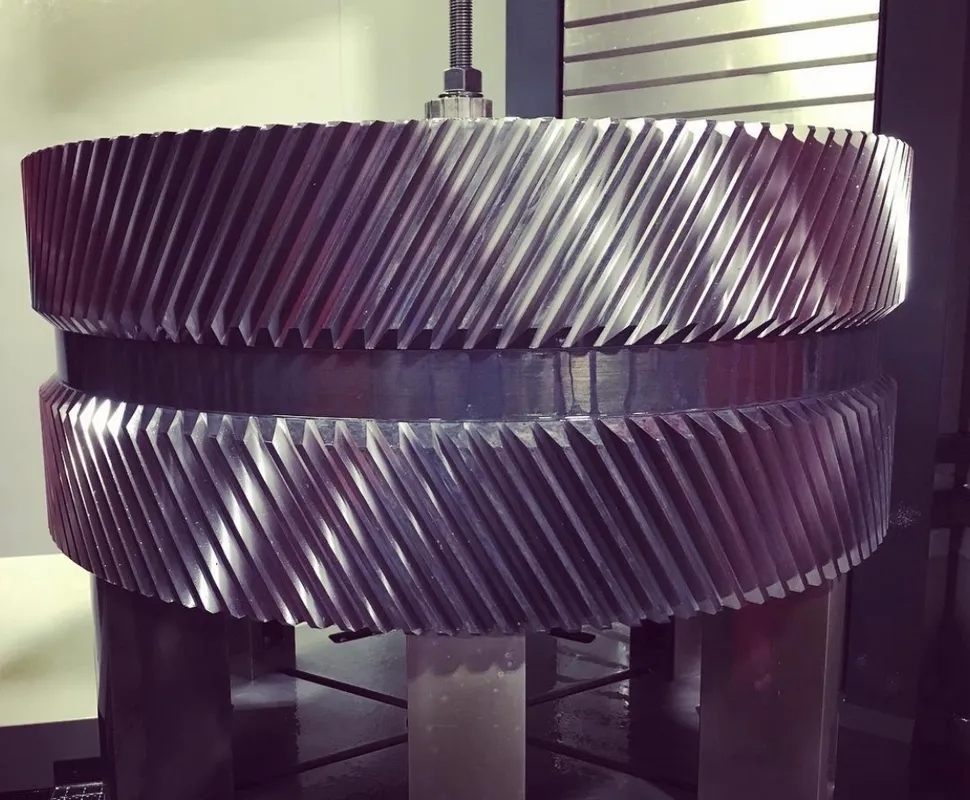

During gearbox repair, the gear backlash can typically be adjusted without the need for replacement. Gear backlash refers to the amount of clearance between mating gears, and it is important to ensure proper functioning of the gearbox. By adjusting the gear backlash, technicians can optimize the gear meshing process, reducing noise and wear on the gears. This adjustment may involve changing shims, adjusting bearing preload, or realigning the gears. Proper adjustment of gear backlash is crucial for the overall performance and longevity of the gearbox. If the gear backlash cannot be adjusted within acceptable limits during repair, then replacement of the gears may be necessary to ensure optimal operation.