Dynamic balancing in pump impeller manufacturing serves the purpose of ensuring that the impeller is properly balanced to minimize vibrations and improve the overall performance of the pump system. By balancing the impeller dynamically, manufacturers can reduce wear and tear on the pump components, increase efficiency, and extend the lifespan of the pump.

Dynamic balancing helps improve the performance of pump impellers by reducing vibrations, which can lead to noise, increased energy consumption, and premature wear on the pump components. A balanced impeller ensures smooth operation, increased efficiency, and optimal performance of the pump system. This results in lower maintenance costs and improved reliability of the pump.

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

Common methods used for dynamic balancing of pump impellers include static balancing, where weights are added or removed to achieve balance, and dynamic balancing, which involves spinning the impeller at high speeds and measuring the vibrations to determine the amount and location of imbalance. Other methods may include laser balancing and computerized balancing systems.

An unbalanced impeller can negatively affect the overall operation of a pump system by causing excessive vibrations, noise, and increased stress on the pump components. This can lead to reduced efficiency, decreased performance, and potential damage to the pump over time. It is crucial to address any imbalance in the impeller to prevent these issues.

The consequences of not performing dynamic balancing on pump impellers can be severe. Without proper balancing, the impeller may experience increased vibrations, leading to noise, reduced efficiency, and premature wear on the pump components. This can result in higher maintenance costs, decreased reliability, and potential failure of the pump system.

Pump impellers should undergo dynamic balancing regularly to maintain optimal performance. The frequency of balancing depends on factors such as the operating conditions, speed, and size of the pump. It is recommended to balance the impeller during the manufacturing process and periodically during maintenance to ensure smooth operation and extend the lifespan of the pump system.

There are industry standards and regulations regarding dynamic balancing of pump impellers to ensure the safety, efficiency, and reliability of pump systems. Organizations such as the American National Standards Institute (ANSI) and the Hydraulic Institute provide guidelines and standards for dynamic balancing procedures to help manufacturers and operators maintain high-quality pump systems. Adhering to these standards can help prevent issues related to unbalanced impellers and ensure optimal performance of pump systems.

Seals in a gearbox should be replaced periodically to ensure optimal performance and prevent leaks. The frequency of seal replacement can vary depending on factors such as the type of gearbox, operating conditions, and maintenance practices. In general, it is recommended to inspect seals regularly for signs of wear or damage, and replace them as needed. Some common indicators that seals may need to be replaced include oil leaks, excessive noise or vibration, and decreased efficiency. By replacing seals in a timely manner, gearbox components can be protected from contamination and premature wear, ultimately extending the lifespan of the equipment.

To mitigate the effects of pump erosion, various measures can be implemented. One effective strategy is to regularly inspect and maintain the pump components to ensure they are in optimal condition. Utilizing erosion-resistant materials for the pump parts, such as ceramic coatings or hardened alloys, can also help prevent erosion damage. Additionally, adjusting the pump operating conditions, such as flow rate and pressure, can reduce the impact of erosion on the pump. Installing protective measures, such as erosion shields or sacrificial coatings, can further safeguard the pump from erosion. Properly sizing the pump and ensuring proper alignment and installation can also help mitigate erosion effects. Overall, a combination of preventative maintenance, material selection, operational adjustments, and protective measures can help minimize the impact of pump erosion.

Diagnosing and repairing pump suction cavitation involves first identifying the symptoms such as noise, vibration, reduced flow rate, and decreased performance. The next step is to inspect the pump for any blockages, leaks, or worn components that could be causing the cavitation. Common causes of cavitation include high suction lift, inadequate NPSH, undersized suction piping, or a clogged strainer. Once the root cause is determined, repairs may involve adjusting the pump speed, increasing the suction pipe diameter, installing a larger pump, or improving the system's NPSH. Regular maintenance and monitoring of the pump system can help prevent cavitation issues in the future.

To identify and repair pump suction side erosion, one must first inspect the pump components for signs of wear, such as pitting, corrosion, or rough surfaces. Common causes of erosion on the suction side of a pump include cavitation, abrasive particles in the fluid, and high flow velocities. To repair the erosion, one can use methods such as applying protective coatings, replacing worn components, or adjusting the pump operation to reduce erosion. It is important to address suction side erosion promptly to prevent further damage to the pump and ensure optimal performance. Regular maintenance and monitoring of the pump system can help prevent erosion issues in the future.

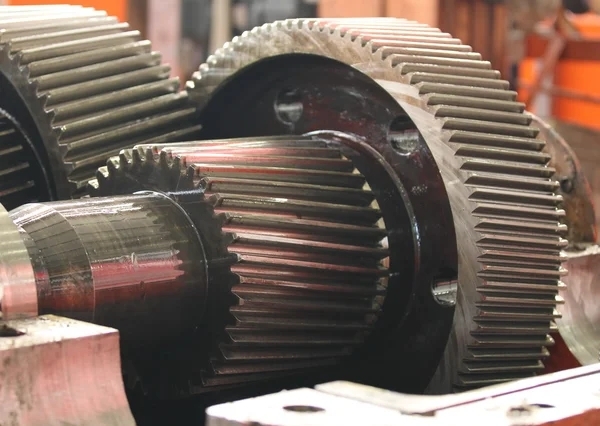

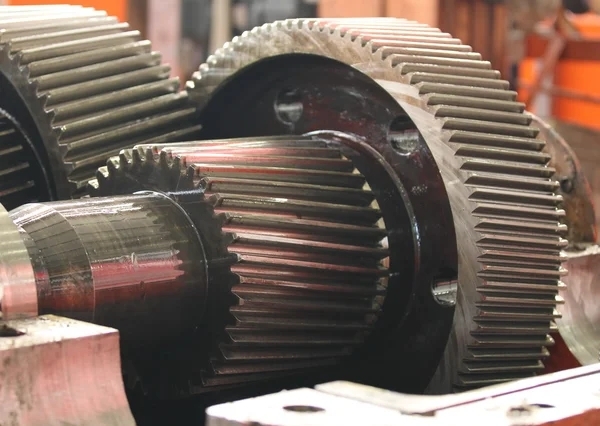

Gearbox bearing failure can be identified by several key signs, including unusual noises such as grinding, whining, or rumbling coming from the transmission. Other indicators may include difficulty shifting gears, vibrations felt through the gear stick or floorboard, and leaks of transmission fluid. In some cases, there may also be a burning smell or visible metal shavings in the transmission fluid. It is important to address these symptoms promptly, as gearbox bearing failure can lead to more extensive damage to the transmission if left untreated. Regular maintenance and inspections can help prevent gearbox bearing failure and ensure the longevity of the transmission system.

To calculate the expected pump bearing lifespan, one must consider various factors such as the type of bearing used, the load and speed at which the pump operates, the lubrication system in place, and the environmental conditions in which the pump is located. By analyzing these factors and consulting manufacturer specifications, engineers can estimate the expected lifespan of the pump bearing. Additionally, conducting regular maintenance and monitoring the condition of the bearing can help prolong its lifespan and prevent unexpected failures. It is important to consider all these factors in order to accurately predict the expected lifespan of a pump bearing.

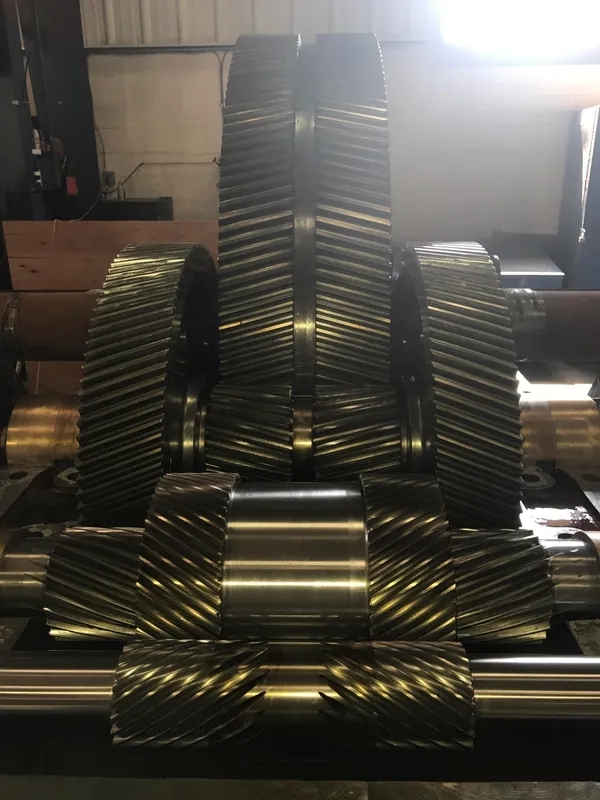

Gearbox gear teeth can indeed be coated with various materials to improve wear resistance. Coatings such as diamond-like carbon (DLC), nitride, and ceramic coatings are commonly used to enhance the durability and longevity of gear teeth. These coatings provide a protective barrier against friction, abrasion, and corrosion, ultimately extending the lifespan of the gears. Additionally, coatings can also improve the overall performance of the gearbox by reducing maintenance requirements and increasing efficiency. Overall, coating gear teeth is a proven method to enhance wear resistance and optimize the functionality of gear systems.