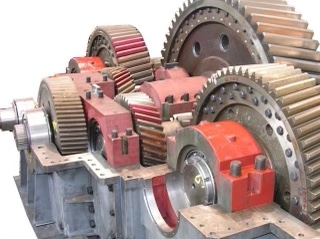

When a damaged gearbox shaft keyway needs to be repaired, one common method is to use a process called keyway broaching. This involves using a broaching tool to remove the damaged material from the keyway and create a new, clean surface for the key to fit into. This method is effective in restoring the functionality of the keyway and ensuring a secure connection between the shaft and the key.

The tools typically needed to repair a gearbox shaft keyway include a broaching tool, a hammer, a press or arbor press, and precision measuring tools such as calipers. The broaching tool is essential for removing the damaged material from the keyway, while the hammer is used to drive the tool into the keyway. The press is used to apply controlled force during the broaching process, and the measuring tools are necessary for ensuring the keyway is repaired to the correct dimensions.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Common causes of gearbox shaft keyway damage include excessive torque or force applied to the key, improper keyway design or machining, and wear and tear over time. If the key is not properly fitted or if the keyway is not machined to the correct specifications, it can lead to damage and eventual failure of the keyway.

When repairing a gearbox shaft keyway, it is important to take specific safety precautions to prevent injury. This includes wearing appropriate personal protective equipment such as gloves and safety glasses, ensuring the work area is clear of any obstructions, and following proper procedures for using the broaching tool and press. Additionally, it is important to work in a well-ventilated area to avoid exposure to any fumes or dust generated during the repair process.

Removing a damaged key from a gearbox shaft keyway involves several steps. First, the area around the keyway should be cleaned to remove any debris or contaminants. Then, a puller tool can be used to extract the key from the keyway. If the key is stuck or difficult to remove, heat or lubrication may be applied to help loosen it. Once the key is removed, the keyway can be inspected for damage and repaired as needed.

To prevent gearbox shaft keyway damage in the future, it is important to ensure that the key and keyway are properly designed and machined to fit together securely. Regular maintenance and inspection of the keyway can help identify any signs of wear or damage early on, allowing for timely repairs to be made. Additionally, using the correct size and type of key for the application can help prevent excessive stress on the keyway.

In addition to traditional methods like keyway broaching, there are alternative methods for repairing a gearbox shaft keyway. One alternative method is to use a keyless locking device, which eliminates the need for a traditional key and keyway altogether. This can be a more efficient and cost-effective solution for some applications, as it eliminates the risk of keyway damage and provides a secure connection between the shaft and the component.

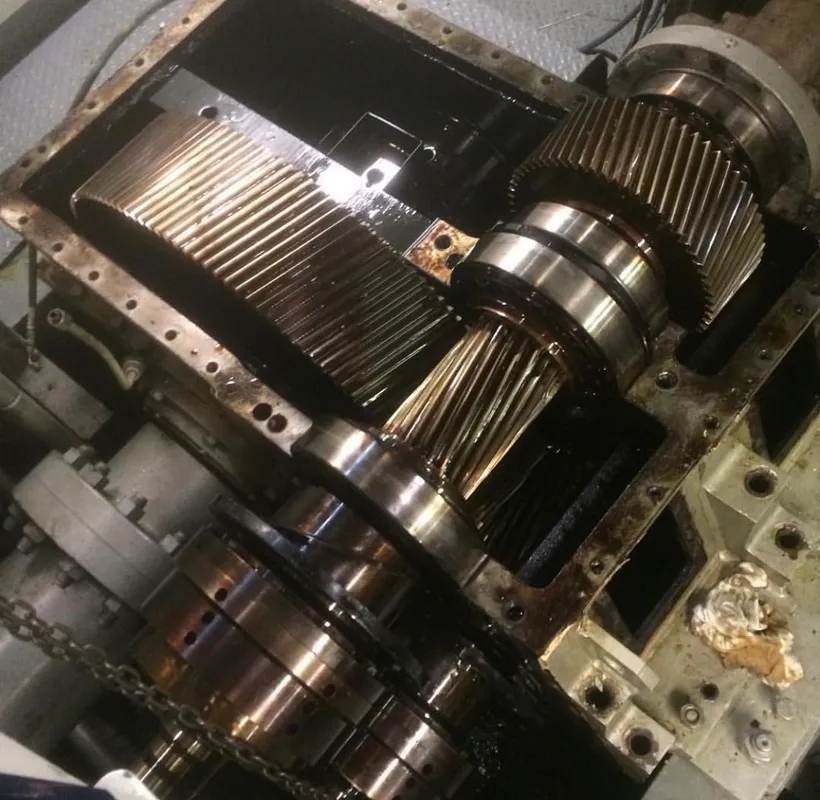

Gearbox lubricants can be filtered and reused in some cases, depending on the level of contamination and the type of filtration system used. Filtration processes such as oil purification, centrifugal separation, and magnetic filtration can help remove contaminants like dirt, metal particles, and water from the lubricant, extending its lifespan. However, in cases of severe contamination or degradation, replacement of the lubricant may be necessary to ensure optimal gearbox performance and prevent damage. Regular monitoring of lubricant condition and implementing proper maintenance practices can help determine whether filtration and reuse are viable options for a specific gearbox system.

During gearbox repair, it is possible to straighten gearbox shafts in some cases, depending on the extent of the damage. Straightening a gearbox shaft involves using specialized tools and techniques to carefully bend the shaft back into its original shape. However, if the shaft is severely bent or damaged beyond repair, replacement may be necessary to ensure the gearbox functions properly. It is important to consult with a professional mechanic or technician to determine the best course of action for repairing gearbox shafts. Additionally, regular maintenance and inspections can help prevent shaft damage and prolong the lifespan of the gearbox.

To diagnose and repair gearbox oil oxidation issues, one must first conduct a thorough inspection of the gearbox system to identify any signs of oxidation, such as a darkening of the oil color, a burnt smell, or increased viscosity. Once oxidation is confirmed, the next step is to drain the old oil and flush the gearbox system to remove any contaminants. After cleaning the system, fresh gearbox oil with antioxidant additives should be added to prevent further oxidation. It is also important to check for any leaks or damaged seals that may be allowing air to enter the system and accelerate oxidation. Regular maintenance and monitoring of oil condition can help prevent gearbox oil oxidation issues in the future.

To diagnose and rectify gear tooth scoring, one must first inspect the gear teeth for any signs of wear, damage, or scoring. This can be done by visually examining the gear teeth or using specialized equipment such as a borescope or gear inspection tool. Once the scoring is identified, the root cause must be determined, which could be due to factors such as improper lubrication, misalignment, overload, or contamination. To rectify the issue, the gear teeth may need to be repaired or replaced, the lubrication system may need to be improved, the gear alignment may need to be adjusted, or the operating conditions may need to be optimized. Regular maintenance and monitoring of the gear system can help prevent future instances of gear tooth scoring.

To diagnose and repair pump discharge side erosion, the technician should first inspect the pump for any signs of erosion, such as wear on the discharge side components, corrosion, or pitting. They can use tools like borescopes or ultrasonic testing to assess the extent of the damage. Once the erosion is identified, the technician can repair it by replacing the worn components, applying protective coatings, or adjusting the pump operation to reduce erosion. It is important to address the root cause of the erosion, which could be related to fluid properties, pump design, or operating conditions, to prevent future damage. Regular maintenance and monitoring can help prevent pump discharge side erosion in the future.