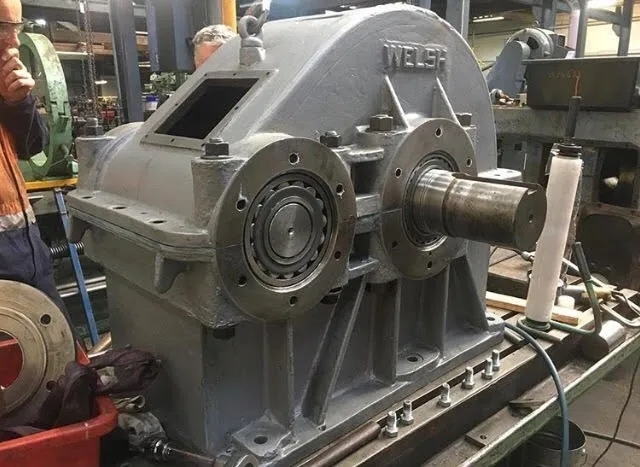

Gear tooth profile resurfacing in gearboxes can be achieved through various methods such as grinding, honing, and milling. Grinding involves using abrasive wheels to remove material from the gear tooth surface, while honing utilizes abrasive stones to smooth and refine the profile. Milling, on the other hand, involves cutting away material using a rotating cutter. Each method has its own advantages and is chosen based on the specific requirements of the gearbox.

The process of gear tooth profile resurfacing plays a crucial role in improving the performance of gearboxes. By restoring the correct tooth geometry and surface finish, resurfacing helps reduce noise, vibration, and wear in the gearbox. This results in smoother operation, increased efficiency, and extended lifespan of the gearbox components. Properly resurfaced gear tooth profiles ensure optimal power transmission and overall functionality of the gearbox.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

Grinding is a preferred method for resurfacing gear tooth profiles due to its precision and efficiency. Grinding allows for tight control over the material removal process, resulting in accurate tooth profiles and surface finishes. Additionally, grinding can be easily automated for mass production, making it a cost-effective solution for gear manufacturers. The ability to achieve high tolerances and surface quality makes grinding a popular choice for gear tooth profile resurfacing.

When using honing for gear tooth profile resurfacing, it is important to consider factors such as the type of abrasive stones, honing pressure, and lubrication. Proper selection of abrasive stones ensures the desired surface finish and removal rate, while controlling honing pressure helps prevent distortion of the gear tooth profile. Lubrication is essential to reduce friction and heat generation during the honing process, ensuring the integrity of the gear tooth surface.

The choice of resurfacing method significantly impacts the durability and longevity of gear tooth profiles in gearboxes. Properly resurfaced gear tooth profiles contribute to efficient power transmission, reduced wear, and increased reliability of the gearbox. The method chosen should align with the material properties of the gears, the required surface finish, and the desired level of precision. By selecting the most suitable resurfacing method, gearboxes can operate at optimal performance levels for an extended period.

Gear tooth profile resurfacing can be done in-house by gear manufacturers with the necessary equipment and expertise, or it can be outsourced to specialized facilities. In-house resurfacing allows for greater control over the process and quality assurance, while outsourcing may offer access to advanced technologies and specialized knowledge. The decision to perform resurfacing in-house or outsource it depends on factors such as cost, time constraints, and the complexity of the gear tooth profiles.

To prolong the effectiveness of gear tooth profile resurfacing in gearboxes, specific maintenance practices are recommended. Regular inspection of gear tooth profiles for signs of wear, misalignment, or damage is essential to identify any issues early on. Proper lubrication and alignment of gears help prevent premature wear and ensure smooth operation. Additionally, following manufacturer guidelines for maintenance intervals and resurfacing procedures can help maximize the lifespan and performance of gear tooth profiles in gearboxes.

Common causes of pump vibration can include unbalanced rotating components, misalignment of pump shafts, worn bearings, cavitation, and excessive fluid flow rates. These issues can be addressed by conducting regular maintenance to ensure proper balance and alignment of rotating parts, replacing worn bearings, adjusting fluid flow rates to optimal levels, and addressing any cavitation issues through proper pump design or installation modifications. Additionally, using vibration monitoring systems can help detect and address any potential vibration issues before they escalate. Proper installation and maintenance procedures are essential in preventing and addressing pump vibration problems.

Pump impeller imbalance can have several implications on the overall performance and efficiency of a pumping system. When the impeller is not properly balanced, it can lead to increased vibration, noise, and wear on the pump components. This imbalance can also result in reduced flow rates, decreased energy efficiency, and potential damage to the pump shaft and bearings. Additionally, an imbalanced impeller can cause cavitation, which can further deteriorate the pump performance and lead to costly repairs. It is crucial to address pump impeller imbalance promptly to prevent these negative consequences and ensure the smooth operation of the pumping system. Regular maintenance and monitoring of the impeller balance are essential to avoid any potential issues.

Helical gears and spur gears are two common types of gears used in gearboxes, each with its own unique characteristics. Helical gears have teeth that are cut at an angle to the gear axis, resulting in a smoother and quieter operation compared to spur gears, which have straight teeth that are parallel to the gear axis. The helical gears also have a larger contact area, which allows for higher torque transmission and better load distribution. However, helical gears tend to produce axial thrust, requiring additional bearings to support the shaft. On the other hand, spur gears are simpler in design and easier to manufacture, making them more cost-effective. They are also more efficient in terms of power transmission due to less sliding friction. Overall, the choice between helical and spur gears in gearboxes depends on factors such as noise level, load capacity, efficiency, and cost.

When deciding between repairing or replacing gearbox components, it is important to consider factors such as the extent of damage, cost of repairs, availability of replacement parts, and overall performance of the gearbox. If the damage is minor and can be easily fixed with a simple repair, it may be more cost-effective to opt for repairing the components. However, if the damage is extensive and the cost of repairs is close to or exceeds the cost of replacement parts, it may be more practical to replace the components altogether. Additionally, if the gearbox is older and showing signs of wear and tear, replacing the components may improve overall performance and longevity. Ultimately, the decision should be based on a thorough assessment of the situation and weighing the pros and cons of each option.

During gear repair, it is possible to reprofile gear teeth instead of replacing them entirely. This process involves reshaping the teeth to restore their proper form and function. By using specialized tools and equipment, technicians can adjust the profile of the teeth to ensure proper meshing and alignment within the gear system. Reprofiling gear teeth can help extend the lifespan of the gear and prevent the need for costly replacements. However, it is important to consult with a professional to determine the best course of action for repairing damaged gear teeth.