Determining whether an industrial gearbox needs repair or replacement can be done by observing certain signs. These signs may include unusual noises, vibrations, leaks, or a decrease in performance efficiency. If any of these symptoms are present, it is advisable to consult a professional technician to assess the gearbox's condition and recommend the appropriate course of action.

When industrial machinery malfunctions, timely repairs are crucial to minimizing downtime and maximizing productivity. To learn more about the importance of maintaining and repairing Industrial Gearbox and Pump Equipment in Dallas, visit: https://precisiongearrepair.com/gearbox-repair/dallas-tx/

Ensuring the proper functioning of industrial gearbox and pump equipment not only enhances operational efficiency but also extends the lifespan of expensive machinery, ultimately saving businesses significant costs in the long run.

Common signs of wear and tear in pump equipment that may require repair include decreased flow rate, increased energy consumption, leaks, unusual noises, and vibrations. These indicators can point to issues such as worn-out seals, damaged impellers, or clogged filters. Regular monitoring and maintenance of pump equipment can help identify these signs early on and prevent further damage.

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

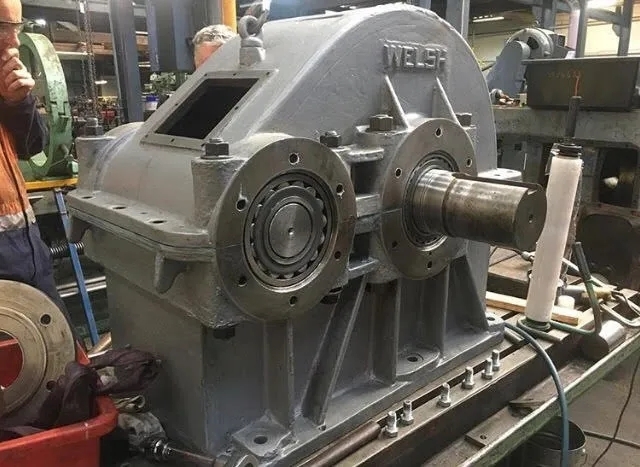

Repairing a damaged industrial gearbox typically involves several steps. First, the gearbox needs to be disassembled to assess the extent of the damage. Then, the faulty components are repaired or replaced, such as gears, bearings, or seals. After the repairs are completed, the gearbox is reassembled, tested, and lubricated before being put back into operation.

Industrial gearboxes and pump equipment should be inspected regularly for maintenance purposes. The frequency of inspections may vary depending on the operating conditions and the manufacturer's recommendations. However, a general guideline is to inspect gearboxes and pumps at least once a year to ensure they are functioning properly and to address any potential issues before they escalate.

Pump equipment failure can be caused by various factors, including cavitation, corrosion, overheating, misalignment, or inadequate lubrication. Cavitation, for example, can lead to erosion of pump components, while corrosion can weaken the pump's structure. Identifying the root cause of the failure is crucial in determining the appropriate repair measures to prevent future breakdowns.

Industrial gearboxes have specific lubrication requirements to prevent damage and prolong their lifespan. Proper lubrication helps reduce friction, dissipate heat, and protect the gearbox components from wear. The type of lubricant, the amount used, and the frequency of lubrication depend on the gearbox's design, operating conditions, and manufacturer's recommendations. Following these guidelines can help maintain the gearbox's efficiency and reliability.

The costs associated with repairing industrial gearboxes and pump equipment can vary depending on the extent of the damage, the parts needed for replacement, and the labor involved. Minor repairs may be relatively inexpensive, while major overhauls or component replacements can be more costly. It is essential to budget for regular maintenance and inspections to prevent unexpected breakdowns and costly repairs in the long run.

To identify and rectify gearbox oil leakage, one should first inspect the gearbox casing, seals, gaskets, and connections for any signs of oil seepage or dripping. Common indicators of a gearbox oil leak include oil spots or puddles underneath the vehicle, a burning smell coming from the engine bay, or low oil levels in the gearbox. Once the source of the leak is identified, the affected seals, gaskets, or connections should be replaced or repaired accordingly. It is important to use the correct type of gearbox oil and ensure that all components are properly tightened to prevent future leaks. Regular maintenance and inspections can help prevent gearbox oil leakage and ensure optimal performance of the vehicle.

To identify and repair pump seal face erosion, one must first inspect the pump seal face for signs of erosion, such as pitting, grooving, or uneven wear. This can be done using visual inspection or by measuring the surface roughness of the seal face. Once erosion is identified, the next step is to determine the root cause, which could be due to abrasive particles in the fluid, improper lubrication, or excessive operating temperatures. To repair the erosion, the seal face may need to be polished or resurfaced using specialized equipment and techniques. Additionally, addressing the underlying cause of the erosion is crucial to prevent future damage and ensure the longevity of the pump seal.

During the repair of pump impellers, it is possible to balance them to ensure optimal performance. This process involves identifying any areas of imbalance and making adjustments to correct them. Balancing can help prevent issues such as vibration, noise, and premature wear. However, in some cases where the impeller is severely damaged or worn, replacement may be necessary to restore the pump to its original efficiency. It is important to consult with a professional technician to determine the best course of action for repairing or replacing pump impellers.

Diagnosing and repairing gearbox oil foaming issues involves first identifying the potential causes of the problem, such as excessive heat, overfilling of the gearbox, or the presence of contaminants in the oil. To diagnose the issue, a mechanic may need to inspect the gearbox for signs of foaming, check the oil level and quality, and assess the operating conditions of the equipment. Once the cause of the foaming is determined, the mechanic can then take appropriate steps to repair the issue, such as draining and replacing the oil, adjusting the oil level, or installing a foam suppressant additive. Regular maintenance and monitoring of the gearbox can help prevent foaming issues from occurring in the future.

Typical symptoms of pump impeller wear may include decreased flow rate, reduced efficiency, increased vibration, cavitation, and noise. As the impeller wears down, it may become unbalanced, leading to vibrations and noise during operation. Additionally, the reduced efficiency can result in decreased flow rate and increased energy consumption. Cavitation, caused by the formation and collapse of vapor bubbles due to low pressure areas around the impeller, can also occur as a result of wear. Overall, monitoring for these symptoms can help identify impeller wear and prevent further damage to the pump system.

The expected lifespan of a gearbox can vary depending on various factors such as the type of gearbox, operating conditions, maintenance practices, and quality of materials used. Generally, a well-maintained gearbox can last anywhere from 5 to 20 years. To prolong the lifespan of a gearbox, regular maintenance is crucial. This includes checking and replacing lubricants, monitoring temperature and vibration levels, inspecting for wear and tear, and addressing any issues promptly. Proper alignment and balancing of components, as well as ensuring proper loading and operating conditions, can also help extend the lifespan of a gearbox. Additionally, using high-quality materials and components during manufacturing or repairs can contribute to increased durability and longevity.

Common causes of gear wear in industrial gearboxes can be attributed to factors such as inadequate lubrication, high operating temperatures, misalignment, overloading, contamination, and poor maintenance practices. Insufficient lubrication can lead to increased friction and wear between gear teeth, while high temperatures can cause thermal expansion and accelerated wear. Misalignment of gears can result in uneven distribution of forces, leading to premature wear on specific areas. Overloading the gearbox beyond its capacity can also cause excessive stress on the gears, resulting in wear. Contamination from dirt, debris, or moisture can further accelerate gear wear by causing abrasive damage. Regular maintenance, including proper lubrication and alignment checks, is essential in preventing gear wear in industrial gearboxes.