When selecting the material for a pump impeller, key factors to consider include the abrasion resistance, corrosion resistance, and strength of the material. The impeller needs to withstand the wear and tear of pumping fluids while maintaining its structural integrity. Additionally, factors such as cost, availability, and ease of manufacturing should also be taken into account to ensure the overall efficiency and longevity of the pump.

The operating temperature plays a crucial role in determining the suitable material for a pump impeller. High temperatures can cause certain materials to degrade or lose their mechanical properties, leading to premature failure of the impeller. It is essential to choose a material that can withstand the specific temperature range of the operating environment to ensure optimal performance and durability of the pump.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Stainless steel is a popular choice for pump impellers due to its excellent corrosion resistance, durability, and strength. It is capable of handling a wide range of fluids, making it a versatile option for various pumping applications. However, stainless steel can be more expensive than other materials, and it may not be as resistant to certain chemicals or abrasive substances, which could limit its suitability in some environments.

The type of fluid being pumped has a significant influence on the selection of material for the impeller. Different fluids can have varying levels of corrosiveness, viscosity, and temperature, which can impact the compatibility of certain materials. For example, corrosive chemicals may require a highly resistant material like titanium, while abrasive slurries may necessitate a material with high abrasion resistance like ceramic.

Corrosion resistance is a critical factor in the material selection process for pump impellers, especially when dealing with corrosive fluids or environments. Choosing a material with excellent corrosion resistance can prevent degradation and prolong the lifespan of the impeller, ultimately reducing maintenance costs and downtime. Materials like stainless steel, titanium, and nickel alloys are commonly used for their superior corrosion resistance properties.

The material of the impeller can significantly impact the efficiency and performance of the pump. Materials with high abrasion resistance can maintain their shape and efficiency over time, resulting in consistent pumping performance. On the other hand, materials that are prone to corrosion or wear may lead to reduced efficiency, increased energy consumption, and ultimately, decreased pump performance. Therefore, selecting the right material is crucial for optimizing the overall efficiency of the pump system.

There are specific industry standards and guidelines to follow when choosing the material for a pump impeller. Organizations like the American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) provide recommendations and specifications for materials used in pump components, including impellers. Following these standards ensures that the selected material meets the necessary requirements for safety, reliability, and performance in various industrial applications. Adhering to industry standards can help manufacturers and operators make informed decisions when selecting the material for pump impellers.

To prevent corrosion in pump housings, various measures can be taken. One effective method is to apply a protective coating, such as epoxy or polyurethane, to the interior surfaces of the housing. Regular maintenance, including cleaning and inspection, can help identify and address any signs of corrosion early on. Using corrosion-resistant materials, such as stainless steel or fiberglass, for the construction of the pump housing can also help prevent corrosion. Additionally, ensuring proper ventilation and drainage to prevent the buildup of moisture can help mitigate the risk of corrosion. Implementing a cathodic protection system or using sacrificial anodes can provide an additional layer of protection against corrosion in pump housings. Regular monitoring and testing of the pump housing for signs of corrosion can help ensure early detection and prompt action to prevent further damage.

To prevent pump cavitation erosion, various measures can be implemented. One effective method is to ensure proper pump sizing and selection to match the specific application requirements. Additionally, maintaining a consistent flow rate and pressure within the system can help reduce the likelihood of cavitation occurring. Installing a cavitation-resistant pump design, such as one with an inducer or a special coating, can also help mitigate erosion. Regular maintenance and inspection of the pump, including checking for any leaks or blockages, can further prevent cavitation erosion. Implementing a proper filtration system to remove any contaminants from the fluid can also help protect the pump from damage. Lastly, ensuring proper installation and alignment of the pump can help optimize its performance and reduce the risk of cavitation erosion.

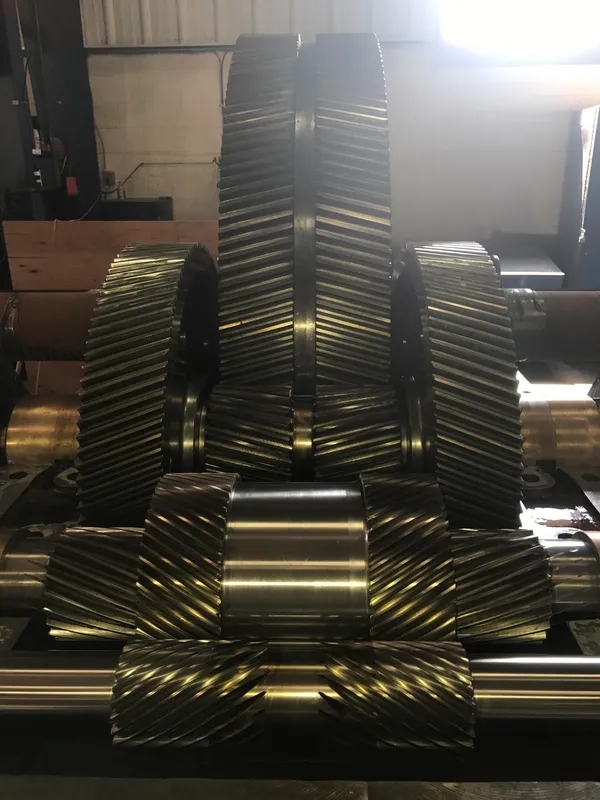

To calculate the required gearbox horsepower for a specific application, one must first determine the torque requirements of the system. This can be done by analyzing the load characteristics, such as the weight being lifted or the force being applied. Once the torque requirements are known, the desired speed of the system must also be taken into consideration. By multiplying the torque and speed values, one can calculate the power needed to drive the system. This power requirement can then be used to select a gearbox with the appropriate horsepower rating to ensure optimal performance and efficiency. Additionally, factors such as gear ratios, efficiency losses, and safety margins should also be considered in the calculation process to account for any potential variations in operating conditions.

When troubleshooting gearbox overheating issues, it is important to first check the transmission fluid levels and quality to ensure proper lubrication. Inspecting the cooling system, including the radiator, hoses, and thermostat, can help identify any blockages or malfunctions that may be causing the overheating. Additionally, examining the clutch system, gear ratios, and bearing wear can provide insight into potential issues contributing to the problem. Regular maintenance, such as changing the transmission fluid and filters, can help prevent overheating in the future. Consulting a professional mechanic or gearbox specialist may be necessary for more complex issues that require specialized knowledge and equipment.

Signs of pump impeller imbalance can include excessive vibration, increased noise levels, reduced efficiency, and premature wear on bearings and seals. To correct pump impeller imbalance, the technician can perform a dynamic balancing procedure to ensure that the impeller is properly aligned and weighted. This may involve adding or removing material from the impeller blades or adjusting the positioning of the impeller within the pump housing. Additionally, the technician may need to check for any obstructions or damage within the pump system that could be contributing to the imbalance. Regular maintenance and monitoring of the pump system can help prevent impeller imbalance issues from occurring in the future.

Preventing rust formation on gearbox surfaces can be achieved by implementing proper maintenance practices such as regular cleaning, applying rust inhibitors, using corrosion-resistant coatings, and ensuring proper ventilation to reduce moisture buildup. Additionally, utilizing protective covers, inspecting for any signs of corrosion, and promptly addressing any issues can help prevent rust from forming on gearbox surfaces. It is also important to store gearboxes in a dry and controlled environment to minimize the risk of rust development. By following these preventative measures, gearbox surfaces can be effectively protected from rust formation, ensuring optimal performance and longevity.