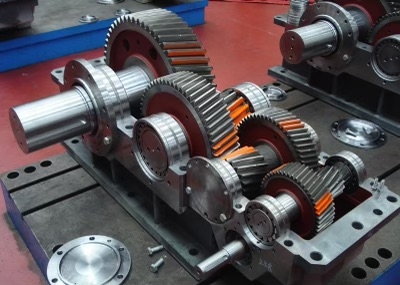

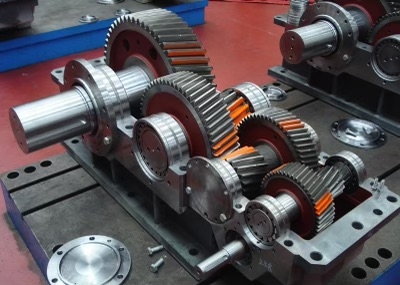

Pitting on gear teeth can significantly impact wear by creating stress concentrations that lead to accelerated fatigue failure. The presence of pits can act as initiation points for cracks to propagate, ultimately causing tooth breakage and reducing the overall lifespan of the gear. Pitting can also increase surface roughness, promoting abrasive wear and further contributing to tooth damage.

Lubrication plays a crucial role in minimizing gear tooth wear by reducing friction and wear between contacting surfaces. Proper lubrication forms a protective film that helps to separate the gear teeth, preventing direct metal-to-metal contact and reducing the likelihood of wear. Additionally, lubricants can help dissipate heat generated during operation, further protecting the gear teeth from excessive wear.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Improper alignment of gears can indeed lead to accelerated gear tooth wear. Misalignment can cause uneven distribution of loads on the gear teeth, leading to increased contact stresses and localized wear. Over time, this can result in premature wear and failure of the gear teeth. Proper alignment is essential to ensure uniform loading and minimize wear on the gear teeth.

The material composition of gears plays a significant role in determining wear resistance. Hardened materials such as alloy steels or carburized steels are commonly used for gears due to their high strength and wear resistance properties. These materials can withstand the high contact stresses and sliding forces experienced during operation, reducing the likelihood of wear on the gear teeth and extending their lifespan.

Common signs of abrasive wear on gear teeth include surface pitting, scoring, and roughening of the tooth profile. Abrasive wear is typically characterized by the removal of material from the gear teeth due to the presence of hard particles or contaminants in the lubricant. This type of wear can lead to increased noise, vibration, and reduced efficiency in gear systems.

Operating temperature can have a significant impact on gear tooth wear. High temperatures can accelerate wear by reducing the effectiveness of lubrication, causing thermal expansion, and promoting oxidation of the gear surfaces. Elevated temperatures can also lead to changes in material properties, such as softening or loss of hardness, which can increase the susceptibility of gear teeth to wear and failure.

Using surface treatments such as carburizing, nitriding, or coating can help reduce gear tooth wear by improving surface hardness, wear resistance, and lubricity. These treatments create a protective layer on the gear teeth, enhancing their ability to withstand contact stresses and sliding forces. Surface treatments can also help reduce friction and wear, leading to longer gear life and improved performance in gear applications.

It is indeed possible to upgrade older gearboxes with newer components to enhance efficiency. By incorporating advanced technologies such as high-performance bearings, precision gears, and improved lubrication systems, the overall performance of the gearbox can be significantly improved. Additionally, retrofitting older gearboxes with modern control systems, sensors, and monitoring devices can further optimize their operation and ensure smoother functionality. This process of upgrading older gearboxes with newer components is known as gearbox modernization and is a cost-effective way to extend the lifespan and enhance the efficiency of existing equipment.

Pump shaft misalignment can have significant implications on the overall performance and efficiency of a pumping system. When the shaft is not properly aligned, it can lead to increased wear and tear on the bearings, seals, and other components of the pump. This can result in decreased reliability, higher maintenance costs, and a shorter lifespan for the equipment. Additionally, misalignment can cause vibration, noise, and overheating, which can further exacerbate the issue and potentially lead to catastrophic failure. Proper alignment of the pump shaft is essential to ensure optimal operation and prevent costly downtime and repairs. Regular monitoring and maintenance of shaft alignment is crucial to avoid these negative consequences and ensure the smooth functioning of the pumping system.

Signs of gearbox seal leakage include visible oil spots or puddles underneath the vehicle, a burning smell coming from the engine, difficulty shifting gears, and low transmission fluid levels. To prevent gearbox seal leakage, regular maintenance and inspections are crucial. This includes checking the transmission fluid levels regularly, replacing the seals as needed, ensuring proper installation of the seals, and using high-quality seals and gaskets. Additionally, avoiding harsh driving conditions and maintaining the proper fluid levels can help prevent gearbox seal leakage. Regularly checking for any signs of leakage and addressing them promptly can also help prevent more serious issues in the future.

Diagnosing and repairing gearbox gear tooth breakage involves a thorough inspection of the gear teeth, gear mesh alignment, lubrication system, and overall gearbox condition. The technician should look for signs of wear, pitting, chipping, or cracking on the gear teeth. Additionally, checking the gear mesh alignment to ensure proper contact and load distribution is crucial in preventing further breakage. Examining the lubrication system for proper oil levels and quality can help identify any issues that may have contributed to the gear tooth breakage. Once the diagnosis is complete, repairing the gearbox gear tooth breakage may involve replacing the damaged gear teeth, adjusting the gear mesh alignment, and improving the lubrication system to prevent future breakage. Regular maintenance and inspections can help prevent gearbox gear tooth breakage and ensure optimal gearbox performance.

Preventing contamination in gearbox lubricants can be achieved through various measures. One effective method is to regularly inspect and replace seals and gaskets to ensure they are intact and functioning properly. Additionally, implementing proper storage practices, such as storing lubricants in sealed containers in a clean and dry environment, can help prevent contamination. Using high-quality filters in the lubrication system can also help remove any particles or debris that may cause contamination. Furthermore, conducting routine oil analysis and monitoring the condition of the lubricant can help detect any signs of contamination early on. Overall, taking proactive steps to maintain the cleanliness and integrity of gearbox lubricants is essential in preventing contamination and ensuring optimal performance of the equipment.

Pump cavitation damage can sometimes be reversed through repair, depending on the extent of the damage and the specific components affected. In some cases, repair techniques such as welding, re-machining, or coating may be able to restore the pump to full functionality. However, in more severe cases where the damage is extensive or irreparable, replacement of the damaged components or the entire pump may be necessary. It is important to assess the damage carefully and consult with a professional to determine the best course of action for addressing pump cavitation damage.