Pump cavitation in industrial systems is primarily caused by low pressure at the pump inlet, which leads to the formation of vapor bubbles in the liquid being pumped. These vapor bubbles can collapse violently when they enter higher pressure areas within the pump, causing damage to the pump components and reducing its efficiency.

The design of pump systems can be optimized to minimize the risk of cavitation by ensuring that the pump is properly sized for the intended application, the suction piping is adequately sized and straight, and the pump is installed at the correct elevation relative to the fluid level. Additionally, using a pump with a higher NPSH (Net Positive Suction Head) margin can help prevent cavitation by providing a greater margin of safety against vapor bubble formation.

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

Proper maintenance plays a crucial role in preventing pump cavitation by ensuring that the pump is operating within its design parameters and that any worn or damaged components are promptly replaced. Regular inspection of the pump, monitoring of suction pressure, and maintaining proper fluid levels are essential maintenance practices to prevent cavitation and prolong the pump's lifespan.

Certain types of pumps, such as centrifugal pumps, are more prone to cavitation than others due to their design characteristics. Centrifugal pumps operate by creating a low-pressure zone at the impeller inlet, which can lead to cavitation if the NPSH requirements are not met. Positive displacement pumps, on the other hand, are less susceptible to cavitation because they do not rely on creating a low-pressure zone to operate.

Operators should be aware of common signs and symptoms of pump cavitation, such as increased noise levels, vibration, reduced flow rate, and decreased pump efficiency. Additionally, visual inspection of the pump components for signs of erosion or pitting can indicate cavitation damage. Monitoring suction pressure and NPSH values can also help detect cavitation early on before it causes significant damage to the pump.

The use of additives or treatments in the fluid being pumped can help prevent cavitation by increasing the fluid's resistance to vapor bubble formation. Anti-cavitation additives, such as defoamers or surfactants, can help stabilize the liquid and reduce the likelihood of vapor bubble formation. Additionally, maintaining proper fluid temperature and pressure can also help prevent cavitation in the pump system.

Advanced technologies and strategies are available for mitigating pump cavitation in high-pressure systems, such as using variable frequency drives to control pump speed and flow rate, installing cavitation-resistant materials in the pump components, and implementing advanced monitoring systems to detect cavitation early on. Additionally, the use of computational fluid dynamics (CFD) simulations can help optimize pump designs and operating conditions to minimize the risk of cavitation in high-pressure systems.

Pump shaft misalignment can have significant implications on bearing wear in a system. When the pump shaft is not properly aligned, it can cause uneven distribution of forces on the bearings, leading to increased friction and wear. This misalignment can result in issues such as vibration, noise, and premature bearing failure. The misalignment can also cause the bearings to operate outside of their intended design parameters, leading to accelerated wear and potential damage. Additionally, misalignment can create additional stress on the bearings, reducing their overall lifespan and increasing the likelihood of costly repairs or replacements. Proper alignment of the pump shaft is essential to ensure optimal performance and longevity of the bearings in a system.

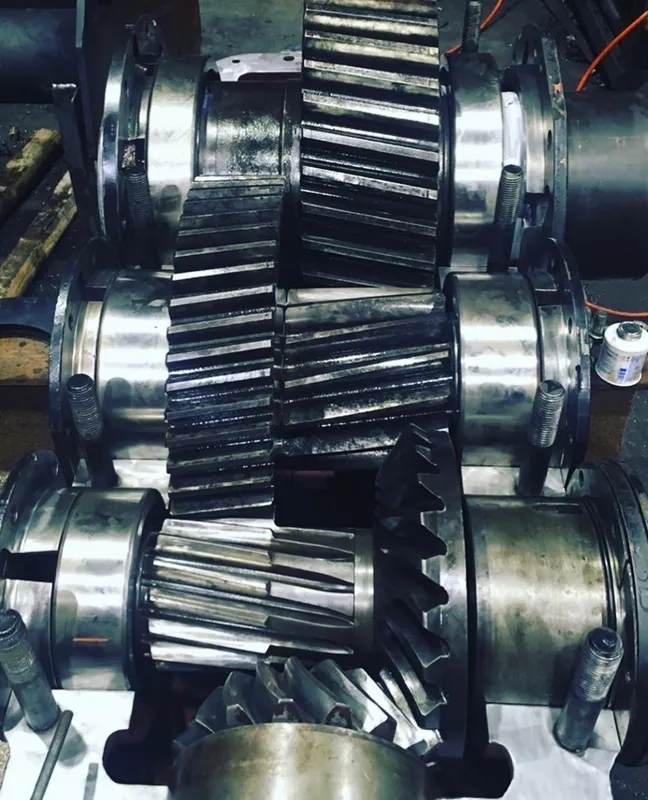

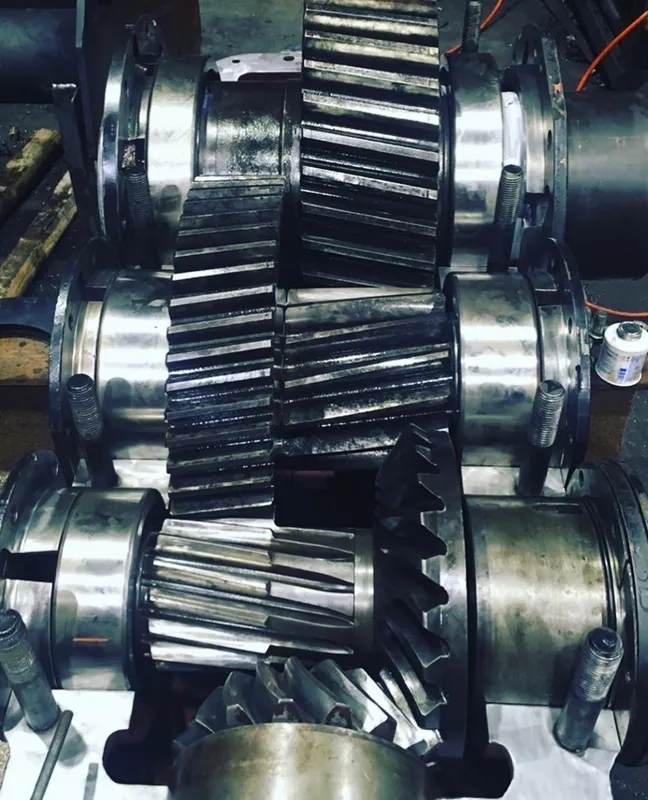

To prevent gearbox rust formation, it is important to implement proper maintenance practices such as regular cleaning, lubrication, and inspection. Using rust inhibitors or protective coatings can also help to prevent oxidation on the gearbox components. Keeping the gearbox dry and storing it in a controlled environment can further reduce the risk of rust formation. Additionally, ensuring that the gearbox is properly sealed and free from any leaks can help to prevent moisture from entering and causing corrosion. Regularly monitoring the gearbox for any signs of rust or corrosion and addressing any issues promptly can help to prolong its lifespan and prevent costly repairs.

During gearbox repair, it is possible to reharden the gears instead of replacing them. Rehardening involves heat treating the gears to restore their hardness and durability. This process can help extend the lifespan of the gears and improve their performance. However, rehardening may not always be possible depending on the extent of damage to the gears. In some cases, replacement may be necessary if the gears are too worn or damaged to be effectively rehardened. It is important to consult with a professional mechanic or gearbox specialist to determine the best course of action for repairing gearbox gears.

To prevent pump impeller cavitation, several measures can be taken. First, ensuring proper pump sizing and selection based on the specific application requirements is crucial. This includes considering factors such as flow rate, pressure, and fluid properties. Additionally, maintaining a consistent and adequate supply of fluid to the pump inlet can help prevent cavitation. Proper installation of the pump, including ensuring proper alignment and clearance, can also reduce the risk of cavitation. Regular maintenance and inspection of the pump, including checking for worn or damaged impeller blades, can help identify and address potential issues before they lead to cavitation. Using anti-cavitation devices such as inducers or pre-rotators can also help mitigate the risk of cavitation in pump impellers.

To calculate the expected gearbox seal lifespan, one must consider various factors such as the type of material used in the seal, the operating conditions of the gearbox, the level of maintenance performed on the gearbox, and the quality of the seal installation. Factors such as temperature, pressure, speed, and exposure to contaminants can all impact the lifespan of the seal. Additionally, the design of the gearbox and the amount of stress placed on the seal during operation can also play a role in determining its longevity. By analyzing these factors and conducting regular inspections and maintenance on the gearbox, one can estimate the expected lifespan of the gearbox seal. It is important to consult with industry experts and manufacturers to ensure accurate calculations and to maximize the lifespan of the gearbox seal.