Key indicators that a gearbox requires preventive maintenance include unusual noises during operation, increased vibration levels, leaks of oil or grease, overheating, and visible wear on gears or bearings. Monitoring these signs can help identify potential issues before they escalate into major problems, leading to costly repairs or downtime.

Gearboxes should be inspected for potential issues on a regular basis, ideally every 3 to 6 months depending on the operating conditions and workload. More frequent inspections may be necessary for gearboxes operating in harsh environments or under heavy loads to ensure early detection of any issues that could lead to failure.

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Common causes of gearbox failure that can be prevented through regular maintenance include lack of lubrication, contamination of the lubricant, misalignment of gears, overloading, and improper installation. By addressing these issues through routine maintenance tasks such as lubrication checks, alignment adjustments, and load monitoring, the lifespan of the gearbox can be significantly extended.

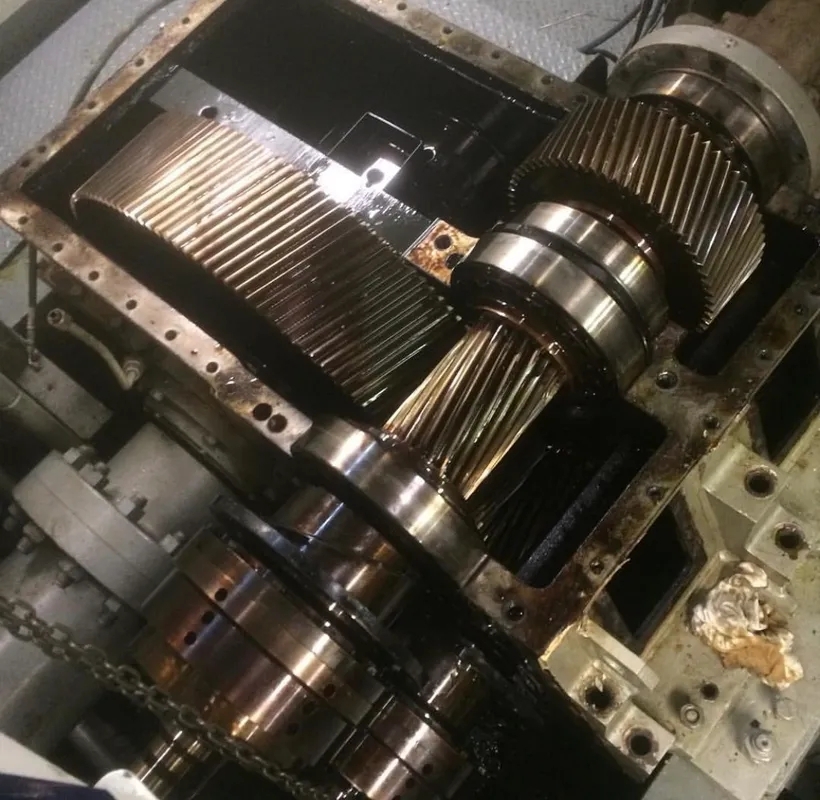

Different types of gearboxes require specific lubrication schedules to ensure optimal performance and longevity. For example, helical gearboxes may need to be lubricated every 6 to 12 months, while worm gearboxes may require more frequent lubrication every 3 to 6 months. Following the manufacturer's recommendations for lubrication type and frequency is crucial to prevent premature wear and failure.

Conducting preventive maintenance on gearboxes may require specific tools and equipment such as grease guns, oil analysis kits, alignment tools, torque wrenches, and vibration meters. These tools help in performing tasks such as lubrication, alignment checks, torque measurements, and vibration analysis to identify potential issues and address them before they lead to gearbox failure.

Vibration analysis can be used to predict potential gearbox failures by monitoring the vibration levels of the gearbox during operation. An increase in vibration amplitude or frequency can indicate issues such as misalignment, worn gears, or bearing damage. By regularly analyzing vibration data and comparing it to baseline measurements, maintenance schedules can be adjusted to address potential problems before they escalate.

Implementing a proactive preventive maintenance schedule for gearboxes in industrial settings offers several benefits, including increased equipment reliability, reduced downtime, extended equipment lifespan, improved safety, and cost savings. By identifying and addressing potential issues before they cause major failures, companies can avoid costly repairs, production delays, and safety hazards, leading to a more efficient and productive operation.

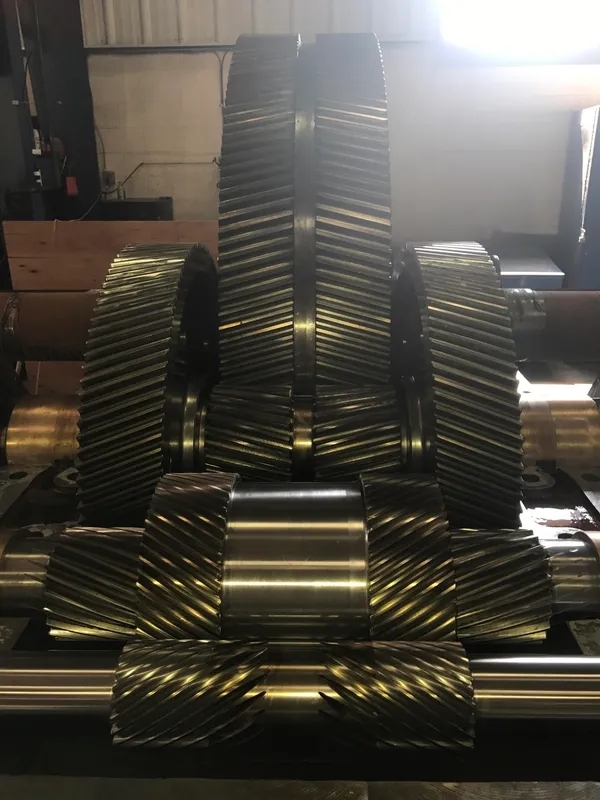

During gear repair, it is possible to reprofile gear teeth instead of replacing them entirely. This process involves reshaping the teeth to restore their proper form and function. By using specialized tools and equipment, technicians can adjust the profile of the teeth to ensure proper meshing and alignment within the gear system. Reprofiling gear teeth can help extend the lifespan of the gear and prevent the need for costly replacements. However, it is important to consult with a professional to determine the best course of action for repairing damaged gear teeth.

To address overheating issues in a pump motor, it is important to first check the cooling system, such as the fan, cooling fins, and coolant levels. Ensure that the motor is properly ventilated and that there are no obstructions blocking airflow. Inspect the motor for any signs of wear or damage that may be causing excessive heat generation. Consider installing a thermal overload protection device to prevent overheating. Regular maintenance, such as cleaning and lubricating moving parts, can also help prevent overheating issues in the pump motor. If the problem persists, it may be necessary to consult a professional technician for further diagnosis and repair.

When it comes to storing spare gearbox parts, it is important to follow best practices to ensure their longevity and functionality. One key practice is to store the parts in a clean, dry environment to prevent corrosion and damage. It is also recommended to organize the parts in a systematic manner, labeling each part clearly for easy identification. Additionally, using proper packaging materials such as plastic bins or containers can help protect the parts from dust and debris. Regularly inspecting the stored parts for any signs of wear or damage is also crucial in maintaining their quality. By following these best practices, individuals can ensure that their spare gearbox parts remain in optimal condition for future use.

When it comes to industrial gearbox repair, selecting the appropriate lubricant is crucial for optimal performance and longevity. Some suitable lubricants for industrial gearbox repair include synthetic oils, mineral oils, gear oils, and grease. Synthetic oils are known for their high performance in extreme temperatures and heavy-duty applications. Mineral oils are commonly used for general-purpose lubrication in industrial gearboxes. Gear oils are specifically formulated to provide protection against wear, corrosion, and oxidation in gear systems. Grease is a semi-solid lubricant that is ideal for applications where oil leakage is a concern. Overall, choosing the right lubricant for industrial gearbox repair depends on factors such as operating conditions, load capacity, and speed requirements.

To detect and repair gearbox leaks, one can start by visually inspecting the gearbox for any signs of oil stains or puddles underneath the vehicle. Using a flashlight, one can check for any visible cracks or damage to the gearbox casing. Additionally, one can perform a pressure test to identify any leaks in the gearbox seals or gaskets. To repair the leaks, one may need to replace the damaged seals or gaskets, tighten any loose bolts, or repair any cracks in the gearbox casing. It is important to use the appropriate tools and equipment to ensure a proper repair and prevent further leaks in the gearbox. Regular maintenance and inspections can help prevent gearbox leaks in the future.

One way to identify symptoms of bearing failure in a pump is to listen for any unusual noises such as grinding, squealing, or knocking sounds coming from the pump. Additionally, an increase in vibration or heat coming from the pump could indicate bearing failure. Another sign to look out for is leaking fluid around the pump, which may be caused by a damaged bearing. It is also important to check for any irregularities in the pump's performance, such as decreased flow rate or pressure. Regular maintenance and monitoring of the pump can help detect bearing failure early on and prevent further damage to the equipment.

Gearbox lubricants can be filtered and reused in some cases, depending on the level of contamination and the type of filtration system used. Filtration processes such as oil purification, centrifugal separation, and magnetic filtration can help remove contaminants like dirt, metal particles, and water from the lubricant, extending its lifespan. However, in cases of severe contamination or degradation, replacement of the lubricant may be necessary to ensure optimal gearbox performance and prevent damage. Regular monitoring of lubricant condition and implementing proper maintenance practices can help determine whether filtration and reuse are viable options for a specific gearbox system.