Common materials used for pump casing repair include stainless steel, carbon steel, bronze, and various types of alloys. These materials are chosen based on their durability, resistance to corrosion, and compatibility with the specific pump system being repaired.

Corrosion in pump casings can be effectively repaired through methods such as abrasive blasting to remove the corroded material, followed by applying protective coatings or linings to prevent further corrosion. Epoxy coatings, ceramic coatings, and polymer linings are commonly used to repair and protect pump casings from corrosion.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

Techniques used to repair cracks in pump casings typically involve welding, brazing, or soldering the cracked areas. Welding processes such as TIG welding or MIG welding are commonly used to fill and repair cracks in pump casings, ensuring structural integrity and preventing further damage.

Specific methods for repairing erosion damage in pump casings include applying protective coatings or linings that are resistant to abrasive wear. Ceramic coatings, polymer linings, and hard-facing techniques are often used to repair erosion damage in pump casings and extend their lifespan.

Cavitation damage in pump casings can be repaired by filling in the cavitated areas with epoxy compounds or weld overlays. Additionally, installing sacrificial wear rings or coatings can help prevent cavitation damage from occurring in the future and protect the pump casing from further deterioration.

The steps involved in welding repairs for pump casings typically include cleaning the damaged area, preheating the casing to the appropriate temperature, welding the cracks or defects using the chosen welding process, and post-weld heat treatment to ensure proper bonding and strength of the repaired area.

Specialized coatings available for pump casing repair include epoxy coatings, ceramic coatings, polymer linings, and corrosion-resistant coatings. These coatings are designed to protect pump casings from various forms of damage, such as corrosion, erosion, and cavitation, and extend the lifespan of the pump system. Proper application of these coatings can significantly improve the performance and durability of pump casings.

Determining the appropriate pump shaft alignment tolerances involves considering factors such as shaft size, coupling type, operating speed, and alignment method. It is important to adhere to industry standards and manufacturer recommendations when setting alignment tolerances for pumps. Common alignment methods include reverse dial indicator, laser alignment, and straight edge alignment. Tolerances can vary depending on the type of pump, such as centrifugal, reciprocating, or rotary pumps. Factors like thermal growth, vibration levels, and shaft material should also be taken into account when determining alignment tolerances. Regular monitoring and adjustment of alignment tolerances can help prevent premature wear and failure of pump components.

Preventing gearbox foaming in lubricants can be achieved by implementing various measures. One effective method is to use anti-foam additives in the lubricant formulation, which help to reduce the formation of foam during operation. Additionally, ensuring that the gearbox is properly vented and that the lubricant is not overfilled can also help prevent foaming. Regularly monitoring the condition of the lubricant and changing it at recommended intervals can further prevent foaming issues. Proper maintenance of the gearbox, including checking for leaks and ensuring proper sealing, can also contribute to preventing foaming in lubricants. Overall, a combination of these measures can help maintain optimal gearbox performance and prevent foaming in lubricants.

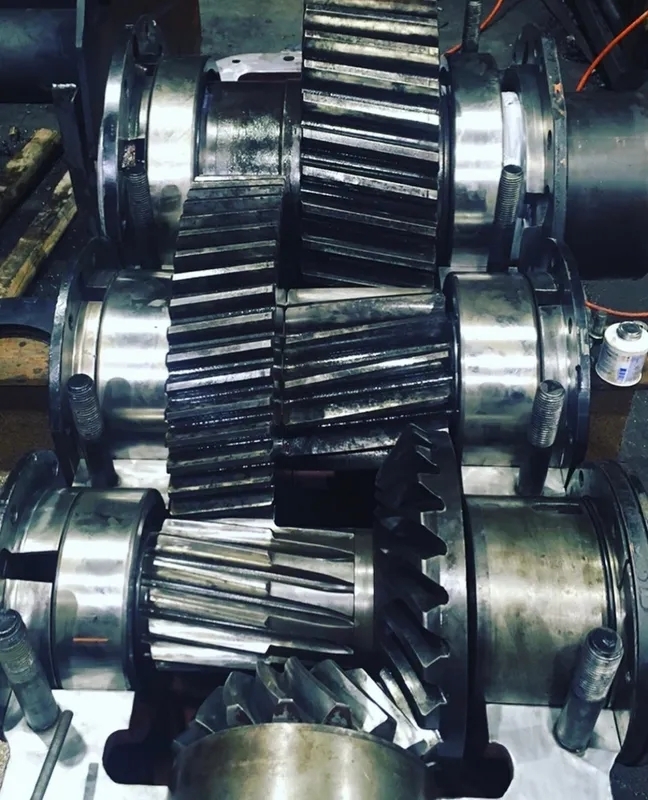

Gear tooth chipping in a gearbox can have significant implications on its performance. When gear teeth become chipped, it can lead to increased friction, vibration, and noise during operation. This can result in decreased efficiency, reduced power transmission, and potential damage to other components within the gearbox. Additionally, chipped gear teeth can cause misalignment and uneven wear, further compromising the overall performance and longevity of the gearbox. It is important to address gear tooth chipping promptly to prevent further deterioration and ensure optimal gearbox functionality. Regular maintenance, proper lubrication, and monitoring of gear tooth condition are essential to prevent issues related to chipping and maintain peak performance of the gearbox.

Signs of pump seal wear include leaking fluid around the pump, increased noise during operation, decreased pump efficiency, and visible damage to the seal itself. Pump seals should be replaced when any of these signs are present to prevent further damage to the pump and ensure optimal performance. It is important to regularly inspect pump seals for wear and tear to avoid costly repairs or downtime. Proper maintenance and timely replacement of pump seals can extend the lifespan of the pump and prevent potential safety hazards.

Cavitation in pump equipment can be caused by a variety of factors, including high fluid velocity, low pressure at the pump inlet, and improper pump design. Other contributing factors may include the presence of air or gases in the fluid, inadequate NPSH (Net Positive Suction Head), and excessive pump speed. Additionally, factors such as pump impeller design, fluid temperature, and the presence of solids in the fluid can also play a role in the occurrence of cavitation. Proper maintenance and operation of pump equipment, as well as ensuring that the system is properly designed and installed, can help mitigate the risk of cavitation.