Signs that indicate a pump coupling needs to be replaced include excessive vibration, misalignment, unusual noises, and visible wear and tear on the coupling components. If there is a noticeable decrease in pump performance or an increase in energy consumption, it may also be a sign that the coupling needs replacement.

Pump couplings should be inspected for wear and tear regularly, ideally during routine maintenance checks. Depending on the type of pump and its usage, inspections can range from monthly to annually. It is essential to monitor the condition of the coupling to prevent unexpected failures and downtime.

Plano Pooped on Dallas. A mechanical failure at a water station dumped more than 1.5 million gallons of hell into White Rock Creek. It started Thursday and was fixed Saturday. The Corinthian Sailing Club on White Rock Lake moved its annual regatta to Lake Ray Hubbard over the weekend, but officials yesterday said they are … Continued The post Leading Off (3/19/24) appeared first on D Magazine.

Posted by on 2024-03-19

The Old Monk, the beloved Henderson Avenue pub, plans to open a second location in Oak Cliff this fall. An alert and pub-loving reader alerted us to this news a few weeks ago, when he wrote to ask about a building being renovated into a restaurant at 810 W. Davis St., next to Bbbop Seoul … Continued The post The Old Monk Will Open a Second Location in Oak Cliff This Fall appeared first on D Magazine.

Posted by on 2024-03-18

Hey! The Cowboys beat the 49ers. In the playoffs? No. On the field at all? No. But they did flip linebacker Eric Kendricks from an initial agreement to sign with San Francisco to join them on a one-year deal. Rejoice! You’re going to have to. Because that is essentially the only thing the Cowboys have … Continued The post Did You Like That Free Agency? I Hope You Did. I Hope You Did Very Much. appeared first on D Magazine.

Posted by on 2024-03-18

It seems like just yesterday that we were celebrating Mardi Gras, but Easter is almost here. And that means a busy week of entertaining out-of-town in-laws, stuffing plastic eggs with candy in the middle of the night, coordinating family photos in some flower bed, and comforting little ones scared of the giant Easter bunny costume. … Continued The post 26 Ways to Celebrate Easter in Dallas-Fort Worth This Month appeared first on D Magazine.

Posted by on 2024-03-18

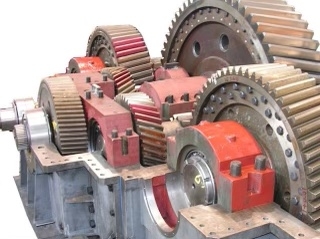

There are several types of pump couplings available for replacement, including gear couplings, grid couplings, elastomeric couplings, and disc couplings. Each type has its own set of advantages and is suitable for different applications. It is crucial to choose the right coupling type based on the specific requirements of the pump system.

It is not always necessary to shut down the entire system when replacing a pump coupling. In some cases, the coupling can be replaced while the pump is still running, using specialized tools and techniques. However, for safety reasons and to ensure proper installation, it is recommended to shut down the system if possible.

When replacing a pump coupling, several safety precautions should be taken. This includes wearing appropriate personal protective equipment, following proper lockout/tagout procedures, and ensuring that the pump system is depressurized and de-energized before starting the replacement process. It is also essential to work in a well-ventilated area and to have a clear understanding of the replacement procedure.

Specific tools are required for replacing a pump coupling, such as alignment tools, torque wrenches, and coupling pullers. These tools help ensure that the replacement process is carried out accurately and efficiently. It is important to use the correct tools for the specific type of coupling being replaced to prevent damage and ensure proper alignment.

Proper alignment when installing a new pump coupling is crucial to prevent premature wear and failure. To ensure proper alignment, it is recommended to use laser alignment tools or dial indicators to accurately align the coupling components. Following the manufacturer's guidelines and specifications for alignment is essential to maintain the efficiency and longevity of the pump system. Regularly checking and adjusting the alignment of the coupling can help prevent costly repairs and downtime in the future.

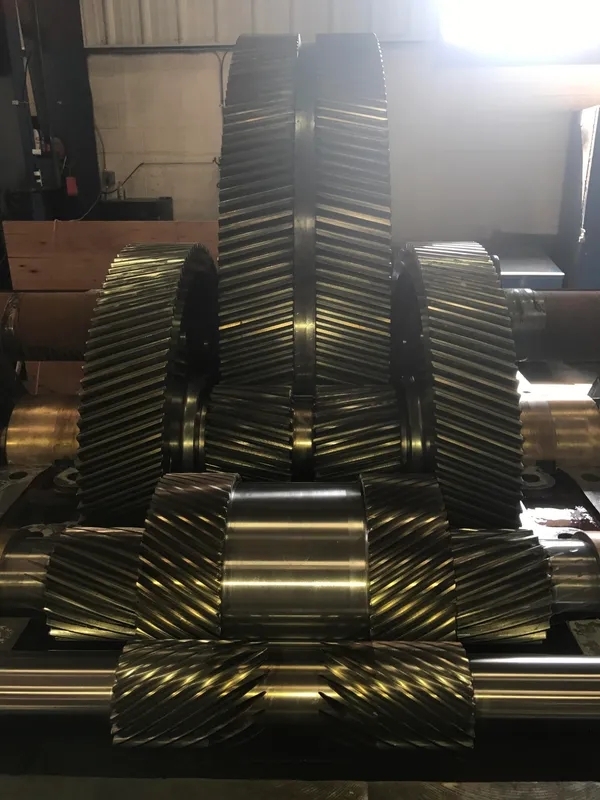

Gearbox gear teeth can indeed be coated with various materials to improve wear resistance. Coatings such as diamond-like carbon (DLC), nitride, and ceramic coatings are commonly used to enhance the durability and longevity of gear teeth. These coatings provide a protective barrier against friction, abrasion, and corrosion, ultimately extending the lifespan of the gears. Additionally, coatings can also improve the overall performance of the gearbox by reducing maintenance requirements and increasing efficiency. Overall, coating gear teeth is a proven method to enhance wear resistance and optimize the functionality of gear systems.

To check gearbox backlash, the technician should first secure the gearbox in place to prevent any movement during the inspection. Next, they should rotate the input shaft in both directions while measuring the amount of free play or movement in the output shaft. This measurement will indicate the amount of backlash present in the gearbox. The technician should compare this measurement to the manufacturer's specifications to determine if the backlash is within acceptable limits. If the backlash is found to be excessive, adjustments may need to be made to the gearbox components to reduce the amount of play and ensure proper operation. Regular monitoring of gearbox backlash is essential to prevent premature wear and damage to the gearbox components.

When determining the appropriate pump impeller diameter for a specific application, engineers typically consider factors such as flow rate, head pressure, fluid viscosity, and pump speed. The impeller diameter plays a crucial role in determining the pump's efficiency and performance. By analyzing the system requirements, including the desired flow rate and pressure, engineers can calculate the required impeller diameter using equations based on fluid dynamics principles. Additionally, considerations such as cavitation, NPSH (Net Positive Suction Head), and impeller design characteristics must be taken into account to ensure optimal pump performance. Conducting thorough analysis and calculations based on the specific application parameters will help determine the most suitable impeller diameter for the pump system.

Signs of gearbox oil contamination can include a burnt smell, dark or cloudy appearance, presence of metal particles, and increased noise or vibration during operation. To prevent gearbox oil contamination, regular maintenance such as oil changes and filter replacements should be performed according to the manufacturer's recommendations. Additionally, ensuring that the gearbox is properly sealed and protected from external contaminants, such as water or dirt, can help prevent contamination. Using high-quality gearbox oil and monitoring oil levels regularly can also help prevent contamination and maintain optimal gearbox performance.

Determining the ideal pump flow rate for a system involves considering various factors such as the system's hydraulic requirements, pipe size, pressure drop, and desired flow velocity. It is important to calculate the system's total dynamic head, which includes the static head (elevation difference), friction losses in the pipes, and any additional head losses. By analyzing the system's flow characteristics, including the required flow rate, maximum flow rate, and operating conditions, engineers can select a pump with the appropriate flow rate capacity. Additionally, conducting pump performance tests and considering factors like pump efficiency and NPSH (Net Positive Suction Head) requirements can help determine the optimal pump flow rate for the system.