Induction hardening and carburizing are both effective methods for surface hardening gearbox gear teeth, but they differ in their processes. Induction hardening involves heating the gear teeth with high-frequency electrical currents and then rapidly cooling them to create a hardened surface layer. On the other hand, carburizing involves introducing carbon into the surface of the gear teeth by heating them in a carbon-rich environment. This process forms a hardened layer of carbides on the surface of the gears, increasing their wear resistance and durability.

Laser hardening and nitriding are both surface hardening techniques used to increase the hardness of gearbox gear teeth. Laser hardening involves using a high-energy laser beam to heat the surface of the gears quickly, followed by rapid cooling to create a hardened layer. Nitriding, on the other hand, involves diffusing nitrogen into the surface of the gears at high temperatures to form nitrides, which increase hardness. While both methods are effective, laser hardening can provide more precise control over the hardened depth and is often faster than nitriding.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Flame hardening can be a versatile surface hardening method for gearbox gear teeth, but there are limitations to its application. Flame hardening involves heating the surface of the gears with a flame and then rapidly cooling them to create a hardened layer. This method is suitable for medium to high carbon steels and can be used on a variety of gear materials. However, it may not be as effective for gears with complex geometries or for materials that are not suitable for rapid heating and cooling.

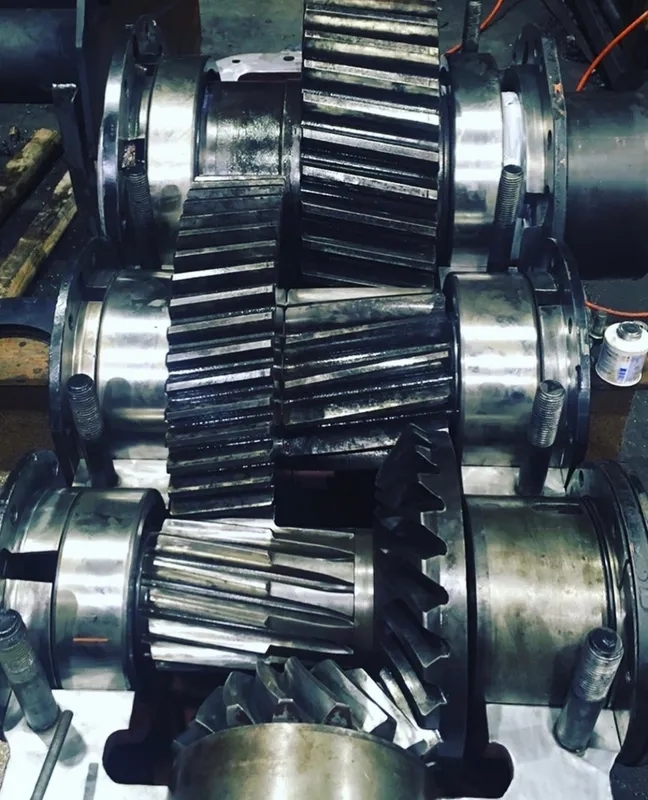

Case hardening offers several advantages over through-hardening for surface hardening gearbox gear teeth. Through-hardening involves heating the gears uniformly to achieve a consistent hardness throughout, while case hardening focuses on hardening only the surface layer of the gears. This allows for a tough core with a hard surface, providing better wear resistance and impact strength. Case hardening also allows for more control over the hardened depth, making it suitable for gears with specific hardness requirements.

The quenching process differs between gear tooth surface hardening methods like induction hardening and nitriding. In induction hardening, the heated gear teeth are rapidly cooled using a quenching medium such as water or oil to achieve the desired hardness. On the other hand, nitriding involves a slow cooling process after the nitrogen diffusion, which helps prevent distortion and cracking of the gears. The choice of quenching method can impact the final hardness and microstructure of the gear teeth.

Certain gear tooth geometries may be more suitable for specific surface hardening methods such as shot peening or laser hardening. Shot peening involves bombarding the gear teeth with small metal particles to create compressive residual stresses, improving fatigue resistance. This method is more suitable for gears with complex geometries or internal features. Laser hardening, on the other hand, is ideal for gears with precise hardening depth requirements or intricate shapes, as the laser beam can be controlled to target specific areas.

Different surface hardening methods for gearbox gear teeth can achieve varying hardness values, impacting the overall performance of the gears. Induction hardening can typically achieve hardness values ranging from 50-60 HRC, providing good wear resistance. Carburizing can result in hardness values of 58-63 HRC, offering excellent wear resistance and fatigue strength. Laser hardening can achieve hardness values of 55-65 HRC, providing precise control over the hardened depth. The choice of surface hardening method should be based on the specific requirements of the gearbox gears to ensure optimal performance and durability.

The implications of pump impeller wear on performance can be significant, leading to decreased efficiency, reduced flow rates, increased energy consumption, and potential damage to other components of the pump system. As the impeller wears down, it may become unbalanced, causing vibrations and noise that can further impact the overall operation of the pump. Additionally, worn impellers can result in cavitation, which can lead to erosion of the impeller and other parts of the pump, ultimately reducing its lifespan. Regular maintenance and monitoring of impeller wear are essential to ensure optimal performance and prevent costly repairs or replacements in the future.

Gear tooth pitting can sometimes be repaired through processes such as grinding, honing, or shot peening. However, the extent of the damage and the specific characteristics of the gear will determine whether repair is a viable option. In some cases, replacement of the gear may be necessary if the pitting is too severe or if the structural integrity of the gear is compromised. It is important to consult with a qualified technician or engineer to assess the damage and determine the best course of action for addressing gear tooth pitting. Regular maintenance and inspection of gears can help prevent pitting and other forms of wear, prolonging the lifespan of the equipment.

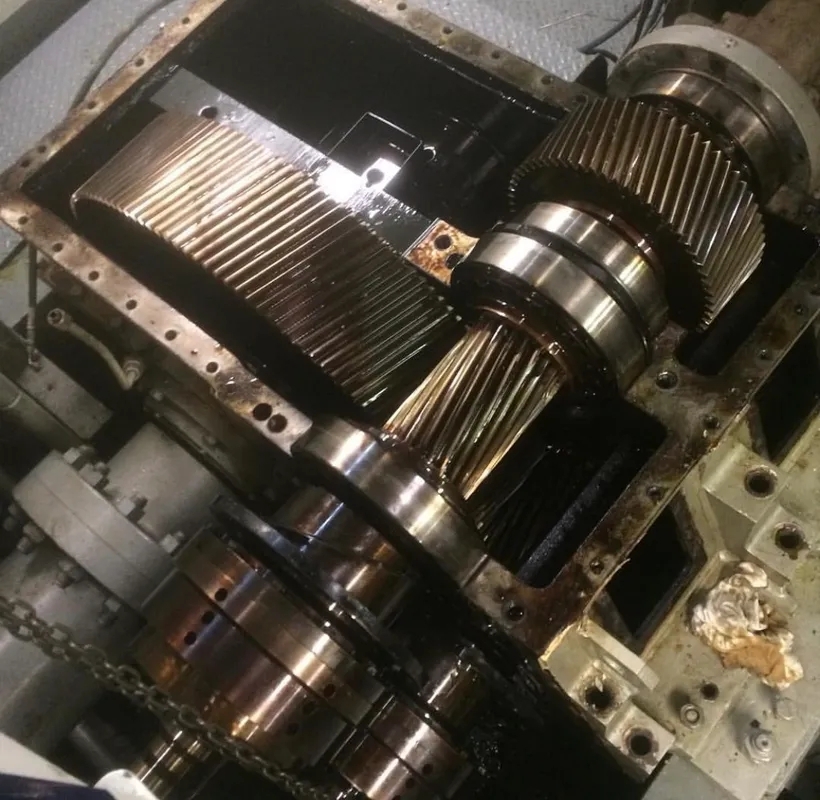

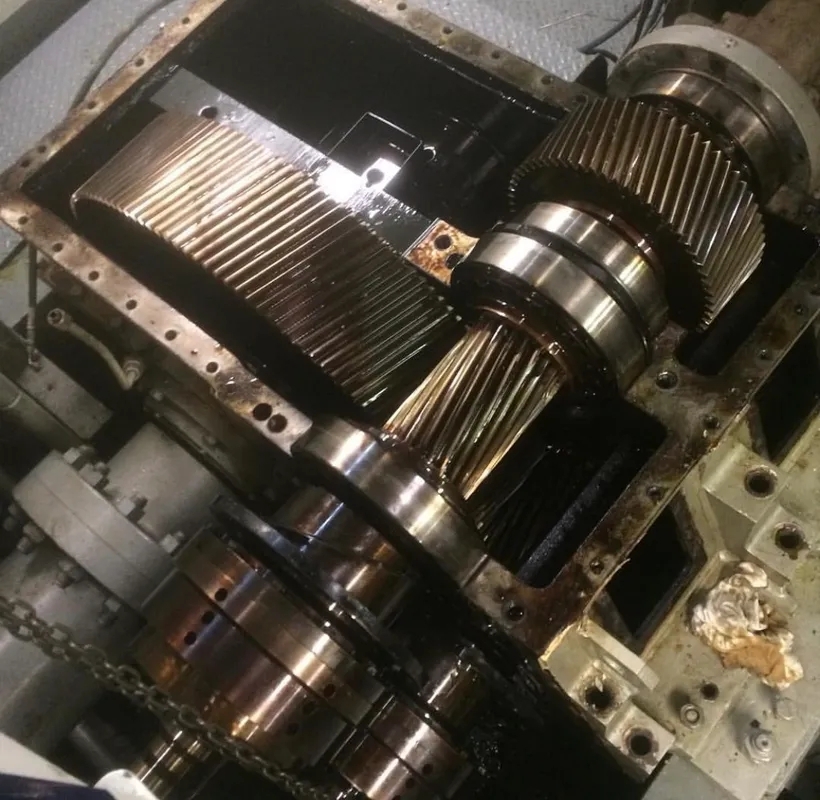

It is indeed possible to upgrade older gearboxes with newer components to enhance efficiency. By incorporating advanced technologies such as high-performance bearings, precision gears, and improved lubrication systems, the overall performance of the gearbox can be significantly improved. Additionally, retrofitting older gearboxes with modern control systems, sensors, and monitoring devices can further optimize their operation and ensure smoother functionality. This process of upgrading older gearboxes with newer components is known as gearbox modernization and is a cost-effective way to extend the lifespan and enhance the efficiency of existing equipment.

Pump shaft misalignment can have significant implications on the overall performance and efficiency of a pumping system. When the shaft is not properly aligned, it can lead to increased wear and tear on the bearings, seals, and other components of the pump. This can result in decreased reliability, higher maintenance costs, and a shorter lifespan for the equipment. Additionally, misalignment can cause vibration, noise, and overheating, which can further exacerbate the issue and potentially lead to catastrophic failure. Proper alignment of the pump shaft is essential to ensure optimal operation and prevent costly downtime and repairs. Regular monitoring and maintenance of shaft alignment is crucial to avoid these negative consequences and ensure the smooth functioning of the pumping system.

Signs of gearbox seal leakage include visible oil spots or puddles underneath the vehicle, a burning smell coming from the engine, difficulty shifting gears, and low transmission fluid levels. To prevent gearbox seal leakage, regular maintenance and inspections are crucial. This includes checking the transmission fluid levels regularly, replacing the seals as needed, ensuring proper installation of the seals, and using high-quality seals and gaskets. Additionally, avoiding harsh driving conditions and maintaining the proper fluid levels can help prevent gearbox seal leakage. Regularly checking for any signs of leakage and addressing them promptly can also help prevent more serious issues in the future.

Diagnosing and repairing gearbox gear tooth breakage involves a thorough inspection of the gear teeth, gear mesh alignment, lubrication system, and overall gearbox condition. The technician should look for signs of wear, pitting, chipping, or cracking on the gear teeth. Additionally, checking the gear mesh alignment to ensure proper contact and load distribution is crucial in preventing further breakage. Examining the lubrication system for proper oil levels and quality can help identify any issues that may have contributed to the gear tooth breakage. Once the diagnosis is complete, repairing the gearbox gear tooth breakage may involve replacing the damaged gear teeth, adjusting the gear mesh alignment, and improving the lubrication system to prevent future breakage. Regular maintenance and inspections can help prevent gearbox gear tooth breakage and ensure optimal gearbox performance.