Air bubbles in the gearbox lubrication system can be detected by observing foaming or bubbling in the oil, as well as unusual noises or vibrations coming from the gearbox. To resolve this issue, it is important to check for any leaks or loose connections in the system that may be allowing air to enter. Additionally, bleeding the system to remove any trapped air and ensuring the correct oil level is maintained can help eliminate air bubbles.

Common causes of oil leaks in gearbox lubrication systems include worn seals, gaskets, or O-rings, as well as loose fittings or damaged components. It is crucial to regularly inspect the system for any signs of leakage, such as oil puddles or stains, and address any issues promptly to prevent further damage to the gearbox and ensure proper lubrication.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

Maintaining the proper oil level in a gearbox lubrication system is essential for optimal performance and longevity. Regularly checking the oil level using the dipstick or sight glass and topping up as needed with the recommended lubricant can help ensure that the gearbox is adequately lubricated and protected from excessive wear and tear.

Signs of gearbox lubrication system contamination may include discolored or milky oil, unusual odors, or increased operating temperatures. To prevent contamination, it is important to use high-quality, clean lubricants, regularly change the oil according to manufacturer recommendations, and keep the system sealed to prevent dirt, water, or other contaminants from entering.

Recommended maintenance intervals for gearbox lubrication systems vary depending on the type of gearbox, operating conditions, and manufacturer guidelines. However, as a general rule of thumb, it is advisable to inspect and service the gearbox lubrication system at least once a year or more frequently for heavy-duty applications or harsh environments.

Monitoring the viscosity of the gearbox lubricant can be done using a viscosity measurement tool or by sending oil samples to a laboratory for analysis. Adjusting the viscosity as needed can help ensure proper lubrication and protection for the gearbox components, especially in extreme temperatures or operating conditions.

Using the wrong type of lubricant in a gearbox lubrication system can lead to increased friction, wear, and overheating of the components. This can result in premature failure of the gearbox, reduced efficiency, and costly repairs. It is crucial to always use the recommended lubricant specified by the manufacturer to maintain optimal performance and prolong the lifespan of the gearbox.

To identify and repair pump suction side erosion, one must first inspect the pump components for signs of wear, such as pitting, corrosion, or rough surfaces. Common causes of erosion on the suction side of a pump include cavitation, abrasive particles in the fluid, and high flow velocities. To repair the erosion, one can use methods such as applying protective coatings, replacing worn components, or adjusting the pump operation to reduce erosion. It is important to address suction side erosion promptly to prevent further damage to the pump and ensure optimal performance. Regular maintenance and monitoring of the pump system can help prevent erosion issues in the future.

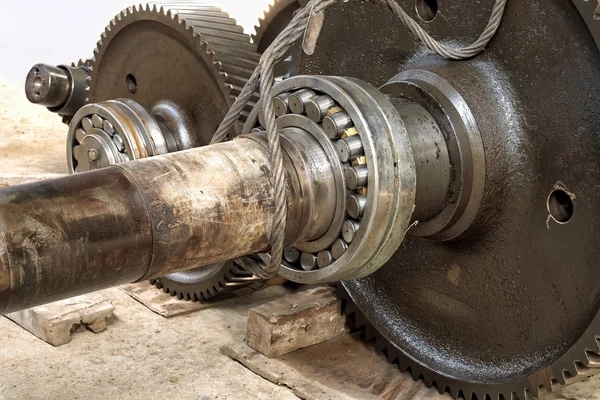

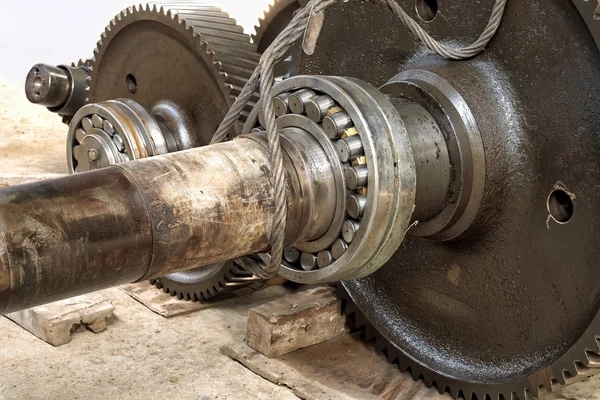

Gearbox bearing failure can be identified by several key signs, including unusual noises such as grinding, whining, or rumbling coming from the transmission. Other indicators may include difficulty shifting gears, vibrations felt through the gear stick or floorboard, and leaks of transmission fluid. In some cases, there may also be a burning smell or visible metal shavings in the transmission fluid. It is important to address these symptoms promptly, as gearbox bearing failure can lead to more extensive damage to the transmission if left untreated. Regular maintenance and inspections can help prevent gearbox bearing failure and ensure the longevity of the transmission system.

To calculate the expected pump bearing lifespan, one must consider various factors such as the type of bearing used, the load and speed at which the pump operates, the lubrication system in place, and the environmental conditions in which the pump is located. By analyzing these factors and consulting manufacturer specifications, engineers can estimate the expected lifespan of the pump bearing. Additionally, conducting regular maintenance and monitoring the condition of the bearing can help prolong its lifespan and prevent unexpected failures. It is important to consider all these factors in order to accurately predict the expected lifespan of a pump bearing.

Gearbox gear teeth can indeed be coated with various materials to improve wear resistance. Coatings such as diamond-like carbon (DLC), nitride, and ceramic coatings are commonly used to enhance the durability and longevity of gear teeth. These coatings provide a protective barrier against friction, abrasion, and corrosion, ultimately extending the lifespan of the gears. Additionally, coatings can also improve the overall performance of the gearbox by reducing maintenance requirements and increasing efficiency. Overall, coating gear teeth is a proven method to enhance wear resistance and optimize the functionality of gear systems.

To check gearbox backlash, the technician should first secure the gearbox in place to prevent any movement during the inspection. Next, they should rotate the input shaft in both directions while measuring the amount of free play or movement in the output shaft. This measurement will indicate the amount of backlash present in the gearbox. The technician should compare this measurement to the manufacturer's specifications to determine if the backlash is within acceptable limits. If the backlash is found to be excessive, adjustments may need to be made to the gearbox components to reduce the amount of play and ensure proper operation. Regular monitoring of gearbox backlash is essential to prevent premature wear and damage to the gearbox components.

When determining the appropriate pump impeller diameter for a specific application, engineers typically consider factors such as flow rate, head pressure, fluid viscosity, and pump speed. The impeller diameter plays a crucial role in determining the pump's efficiency and performance. By analyzing the system requirements, including the desired flow rate and pressure, engineers can calculate the required impeller diameter using equations based on fluid dynamics principles. Additionally, considerations such as cavitation, NPSH (Net Positive Suction Head), and impeller design characteristics must be taken into account to ensure optimal pump performance. Conducting thorough analysis and calculations based on the specific application parameters will help determine the most suitable impeller diameter for the pump system.

Signs of gearbox oil contamination can include a burnt smell, dark or cloudy appearance, presence of metal particles, and increased noise or vibration during operation. To prevent gearbox oil contamination, regular maintenance such as oil changes and filter replacements should be performed according to the manufacturer's recommendations. Additionally, ensuring that the gearbox is properly sealed and protected from external contaminants, such as water or dirt, can help prevent contamination. Using high-quality gearbox oil and monitoring oil levels regularly can also help prevent contamination and maintain optimal gearbox performance.