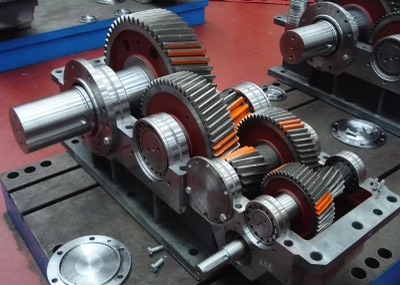

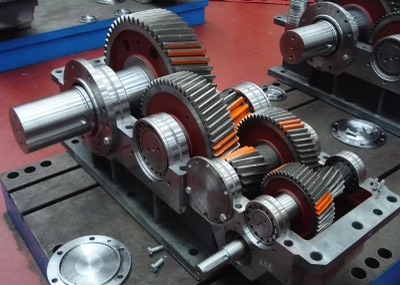

The gear tooth contact pattern analysis method is crucial in determining the efficiency of a gearbox by providing insights into how the gear teeth are interacting during operation. By analyzing the contact pattern, engineers can identify any irregularities or misalignments that may be causing increased friction, wear, or noise in the gearbox. This method helps in optimizing the gear design and alignment to ensure smooth and efficient power transmission within the gearbox.

Several key factors influence the contact pattern of gear teeth in a gearbox, including gear alignment, tooth profile accuracy, load distribution, lubrication, and material properties. Proper alignment and accurate tooth profiles are essential for achieving a uniform contact pattern and minimizing stress concentrations. Additionally, the distribution of load across the gear teeth, the effectiveness of the lubrication system, and the material properties of the gears all play a significant role in determining the contact pattern.

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

Yes, the gear tooth contact pattern analysis method can be used to predict potential gear failures in advance by identifying abnormal contact patterns that may lead to premature wear or failure. By analyzing the contact pattern, engineers can detect issues such as uneven loading, misalignment, or insufficient lubrication that could cause accelerated wear or tooth breakage. This proactive approach allows for timely maintenance or design modifications to prevent costly downtime and repairs.

The lubrication system has a significant impact on the gear tooth contact pattern in a gearbox. Proper lubrication is essential for reducing friction, dissipating heat, and preventing wear between the gear teeth. Inadequate lubrication can lead to increased contact pressures, surface damage, and accelerated wear, resulting in an irregular contact pattern. By ensuring the proper lubrication system design and maintenance, engineers can optimize the contact pattern for improved efficiency and longevity of the gearbox.

The gear material plays a crucial role in the contact pattern analysis of gear teeth as it determines the strength, hardness, and wear resistance of the gears. The material properties influence the contact stresses, surface fatigue, and wear characteristics of the gear teeth, which directly impact the contact pattern. By selecting the appropriate gear material based on the application requirements, engineers can optimize the contact pattern for maximum performance and durability of the gearbox.

There are software tools available for simulating and analyzing gear tooth contact patterns, such as finite element analysis (FEA) software and gear design software. These tools allow engineers to model the gear geometry, loading conditions, material properties, and lubrication effects to predict the contact pattern and analyze the stress distribution on the gear teeth. By using these software tools, engineers can optimize the gear design, alignment, and material selection to achieve the desired contact pattern and performance goals.

The gear tooth contact pattern analysis method can be used to optimize the design of a gearbox for maximum performance by identifying areas of improvement in the gear geometry, alignment, material selection, and lubrication system. By analyzing the contact pattern, engineers can make informed decisions to enhance the load distribution, reduce stress concentrations, improve lubrication effectiveness, and minimize wear on the gear teeth. This optimization process helps in achieving a more efficient and reliable gearbox design that meets the performance requirements and ensures long-term durability.

The expected lifespan of a gearbox can vary depending on various factors such as the type of gearbox, operating conditions, maintenance practices, and quality of materials used. Generally, a well-maintained gearbox can last anywhere from 5 to 20 years. To prolong the lifespan of a gearbox, regular maintenance is crucial. This includes checking and replacing lubricants, monitoring temperature and vibration levels, inspecting for wear and tear, and addressing any issues promptly. Proper alignment and balancing of components, as well as ensuring proper loading and operating conditions, can also help extend the lifespan of a gearbox. Additionally, using high-quality materials and components during manufacturing or repairs can contribute to increased durability and longevity.

Common causes of gear wear in industrial gearboxes can be attributed to factors such as inadequate lubrication, high operating temperatures, misalignment, overloading, contamination, and poor maintenance practices. Insufficient lubrication can lead to increased friction and wear between gear teeth, while high temperatures can cause thermal expansion and accelerated wear. Misalignment of gears can result in uneven distribution of forces, leading to premature wear on specific areas. Overloading the gearbox beyond its capacity can also cause excessive stress on the gears, resulting in wear. Contamination from dirt, debris, or moisture can further accelerate gear wear by causing abrasive damage. Regular maintenance, including proper lubrication and alignment checks, is essential in preventing gear wear in industrial gearboxes.

When determining the appropriate gearbox oil viscosity for a specific application, it is important to consider factors such as operating temperature, load, speed, and gear type. The viscosity of the oil should be selected based on the manufacturer's recommendations, taking into account the specific requirements of the gearbox. It is crucial to choose an oil viscosity that will provide adequate lubrication and protection for the gears, bearings, and other components within the gearbox. Additionally, considering the environmental conditions and the desired performance characteristics of the gearbox can help in selecting the most suitable viscosity grade. Conducting thorough research and consulting with experts in the field can also aid in determining the optimal gearbox oil viscosity for a particular application.

To identify and address gear tooth wear patterns, one must first conduct a thorough inspection of the gear teeth using tools such as micrometers, calipers, and magnifying glasses. Common wear patterns to look for include pitting, scoring, spalling, and abrasive wear. Once identified, the root cause of the wear pattern must be determined, which could be due to factors such as improper lubrication, misalignment, overloading, or material defects. Addressing the wear pattern may involve adjusting the lubrication schedule, realigning the gears, reducing the load on the gears, or replacing the gears altogether. Regular monitoring and maintenance of gear teeth are essential to prevent excessive wear and ensure optimal performance of the machinery.

To minimize gear noise during operation, several measures can be taken. One approach is to ensure proper lubrication of the gears to reduce friction and wear, which can contribute to noise generation. Additionally, using high-quality materials for the gears and maintaining them regularly can help prevent excessive noise. Another strategy is to design the gears with precision to minimize backlash and ensure proper meshing, as this can also impact noise levels. Implementing sound-absorbing materials or enclosures around the gear system can further reduce noise transmission. Furthermore, adjusting the gear teeth profile and spacing can help optimize the gear meshing process and decrease noise. Overall, a combination of proper maintenance, design considerations, and noise-reducing techniques can effectively minimize gear noise during operation.

Determining the appropriate clearance for pump impellers involves considering factors such as impeller diameter, shaft size, and operating conditions. The clearance between the impeller and the pump casing is crucial for optimal performance and efficiency. It is important to follow manufacturer guidelines and specifications to ensure the correct clearance is maintained. Factors such as fluid viscosity, temperature, and pressure can also impact the clearance requirements. Regular maintenance and monitoring of the clearance is essential to prevent issues such as cavitation and wear. Adjustments to the clearance may be necessary based on the specific application and operating conditions of the pump system.