The viscosity of the lubricant plays a crucial role in the performance of a gearbox lubrication system retrofit. The viscosity determines the lubricant's ability to flow and adhere to the gears, bearings, and other components within the gearbox. If the viscosity is too low, the lubricant may not provide sufficient protection and lubrication, leading to increased friction, wear, and potential damage to the gearbox. On the other hand, if the viscosity is too high, it may impede the flow of the lubricant, causing inadequate lubrication and potential overheating of the gearbox components.

Using synthetic lubricants in a gearbox lubrication system retrofit offers several advantages. Synthetic lubricants are engineered to provide superior performance in terms of viscosity stability, thermal resistance, and wear protection. They have a more consistent molecular structure compared to conventional mineral oils, which allows them to maintain their viscosity and lubricating properties over a wider range of temperatures. Additionally, synthetic lubricants typically have a longer service life, reducing the frequency of maintenance and replacement intervals for the gearbox.

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

Blackstone is a new investor in Dallas-based Aligned Data Centers. The world’s largest alternative asset manager, with $1 trillion in assets, has provided a $600 million senior secured credit facility to support the development of Aligned’s newest and largest data center in Utah, a two-story, 80 MW build-to suit project. “Blackstone’s support contributes to Aligned’s continued growth in … Continued The post Blackstone Provides Aligned Data Centers with $600 Million Credit Facility appeared first on D Magazine.

Posted by on 2024-03-15

People are coming to North Texas, but they are not moving to Dallas. The regional success story told in this week’s Census data dump—8.1 million people now call the region home for the first time—is not actually a tale about the center of our metro area, Dallas County, which charted a meager growth that was … Continued The post The Depressing Reality About Dallas in the New U.S. Census Numbers appeared first on D Magazine.

Posted by on 2024-03-15

The operating temperature of the gearbox is a critical factor in determining the most suitable lubrication system retrofitting techniques. High operating temperatures can accelerate the degradation of lubricants, leading to reduced viscosity, increased friction, and wear on gearbox components. In such cases, retrofitting the gearbox with a cooling system or using lubricants with higher thermal stability can help maintain optimal operating conditions and prolong the lifespan of the gearbox.

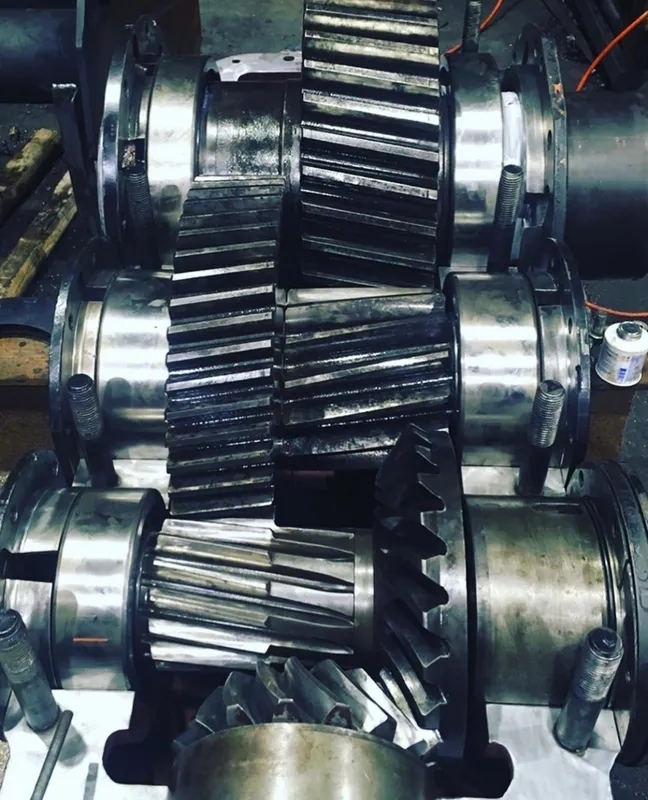

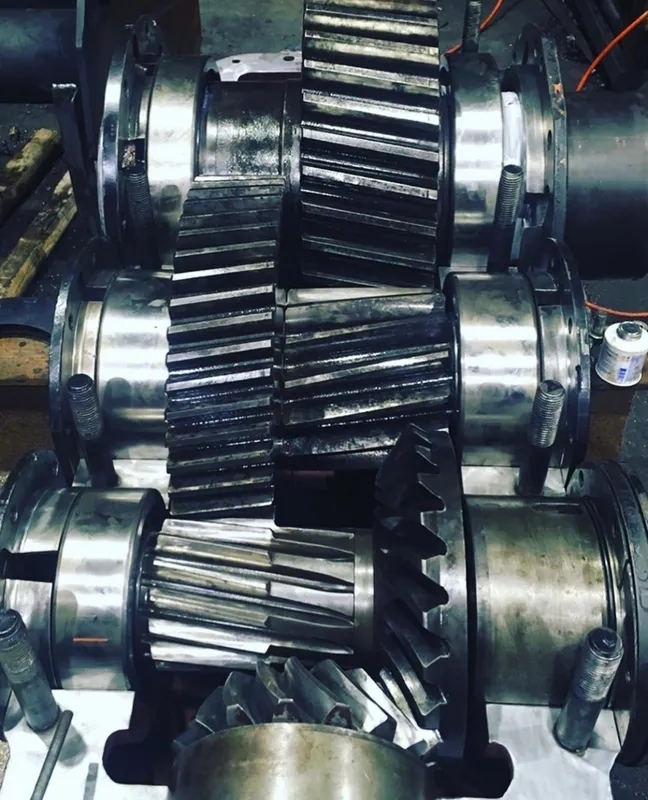

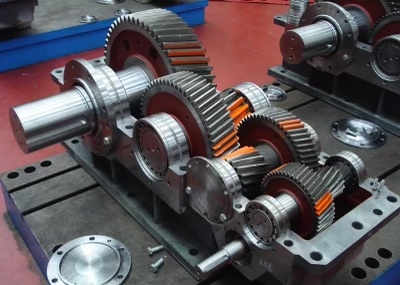

The gear type in a gearbox influences the choice of lubrication system retrofit. Different gear types, such as spur gears, helical gears, bevel gears, or worm gears, have unique lubrication requirements based on their design, load distribution, and operating conditions. For example, helical gears may require lubricants with higher film strength to withstand the sliding action between gear teeth, while worm gears may need lubricants with extreme pressure additives to prevent wear under heavy loads. Understanding the specific gear type is essential in selecting the most appropriate lubrication system retrofit for the gearbox.

Optimizing the frequency of maintenance intervals through proper gearbox lubrication system retrofitting involves selecting the right lubricant, monitoring its performance, and implementing proactive maintenance practices. By choosing a high-quality lubricant that meets the gearbox's requirements and operating conditions, the need for frequent oil changes and component replacements can be reduced. Regular monitoring of the lubricant condition, temperature, and wear debris can help identify potential issues early on and prevent costly downtime. Implementing a proactive maintenance schedule, including lubricant analysis and equipment inspections, can further extend the lifespan of the gearbox and optimize maintenance intervals.

Using the wrong lubricant in a gearbox lubrication system retrofit can have severe consequences on the performance and lifespan of the gearbox. Incompatible lubricants may lead to increased friction, wear, and overheating of gearbox components, resulting in premature failure and costly repairs. Using a lubricant with the wrong viscosity, additives, or thermal stability can compromise the lubrication system's effectiveness and jeopardize the gearbox's reliability. It is essential to carefully select the appropriate lubricant based on the gearbox's requirements and operating conditions to avoid potential consequences of using the wrong lubricant in a retrofit.

The design of the gearbox housing can significantly influence the effectiveness of a lubrication system retrofit. The housing design determines the accessibility of lubrication points, the distribution of lubricant within the gearbox, and the protection of components from contaminants and external factors. A well-designed gearbox housing with proper sealing, drainage, and ventilation features can enhance the lubrication system's efficiency and longevity. Retrofitting the gearbox with additional lubrication channels, filters, or cooling systems may be necessary to optimize lubricant flow, reduce friction, and maintain the gearbox's performance under varying operating conditions. Consideration of the gearbox housing design is essential in ensuring the success of a lubrication system retrofit.

It is indeed possible to upgrade older gearboxes with newer components to enhance efficiency. By incorporating advanced technologies such as high-performance bearings, precision gears, and improved lubrication systems, the overall performance of the gearbox can be significantly improved. Additionally, retrofitting older gearboxes with modern control systems, sensors, and monitoring devices can further optimize their operation and ensure smoother functionality. This process of upgrading older gearboxes with newer components is known as gearbox modernization and is a cost-effective way to extend the lifespan and enhance the efficiency of existing equipment.

Pump shaft misalignment can have significant implications on the overall performance and efficiency of a pumping system. When the shaft is not properly aligned, it can lead to increased wear and tear on the bearings, seals, and other components of the pump. This can result in decreased reliability, higher maintenance costs, and a shorter lifespan for the equipment. Additionally, misalignment can cause vibration, noise, and overheating, which can further exacerbate the issue and potentially lead to catastrophic failure. Proper alignment of the pump shaft is essential to ensure optimal operation and prevent costly downtime and repairs. Regular monitoring and maintenance of shaft alignment is crucial to avoid these negative consequences and ensure the smooth functioning of the pumping system.

Signs of gearbox seal leakage include visible oil spots or puddles underneath the vehicle, a burning smell coming from the engine, difficulty shifting gears, and low transmission fluid levels. To prevent gearbox seal leakage, regular maintenance and inspections are crucial. This includes checking the transmission fluid levels regularly, replacing the seals as needed, ensuring proper installation of the seals, and using high-quality seals and gaskets. Additionally, avoiding harsh driving conditions and maintaining the proper fluid levels can help prevent gearbox seal leakage. Regularly checking for any signs of leakage and addressing them promptly can also help prevent more serious issues in the future.

Diagnosing and repairing gearbox gear tooth breakage involves a thorough inspection of the gear teeth, gear mesh alignment, lubrication system, and overall gearbox condition. The technician should look for signs of wear, pitting, chipping, or cracking on the gear teeth. Additionally, checking the gear mesh alignment to ensure proper contact and load distribution is crucial in preventing further breakage. Examining the lubrication system for proper oil levels and quality can help identify any issues that may have contributed to the gear tooth breakage. Once the diagnosis is complete, repairing the gearbox gear tooth breakage may involve replacing the damaged gear teeth, adjusting the gear mesh alignment, and improving the lubrication system to prevent future breakage. Regular maintenance and inspections can help prevent gearbox gear tooth breakage and ensure optimal gearbox performance.

Preventing contamination in gearbox lubricants can be achieved through various measures. One effective method is to regularly inspect and replace seals and gaskets to ensure they are intact and functioning properly. Additionally, implementing proper storage practices, such as storing lubricants in sealed containers in a clean and dry environment, can help prevent contamination. Using high-quality filters in the lubrication system can also help remove any particles or debris that may cause contamination. Furthermore, conducting routine oil analysis and monitoring the condition of the lubricant can help detect any signs of contamination early on. Overall, taking proactive steps to maintain the cleanliness and integrity of gearbox lubricants is essential in preventing contamination and ensuring optimal performance of the equipment.