Various methods are used to test the hardness of pump impeller materials, including Rockwell, Brinell, and Vickers hardness tests. These tests involve applying a specific amount of force to the material's surface and measuring the depth or size of the indentation left behind. Each method has its own advantages and limitations, making it important to choose the most appropriate one based on the material being tested and the desired level of accuracy.

The Rockwell hardness test and the Brinell hardness test are both commonly used to assess the hardness of pump impeller materials. While the Rockwell test measures the depth of penetration of an indenter under a specific load, the Brinell test measures the diameter of the indentation left by a hard steel ball. The Rockwell test is typically faster and more convenient, while the Brinell test is better suited for softer materials or larger samples.

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

George Dahl was one of the architects who built Dallas. He certainly was the drive behind Fair Park, leading the planning and construction of 26 Art Deco-style buildings ahead of the 1936 Texas Centennial Exposition. He divided the park into four sub-districts, centered upon the 700-foot-long Esplanade that led to the ornate Hall of State. … Continued The post <i>D Magazine’</i>s 50 Greatest Stories: The Tragic End of Architect George Dahl’s Life appeared first on D Magazine.

Posted by on 2024-03-15

The Vickers hardness test is another method that can accurately determine the hardness of pump impeller materials. This test involves applying a load using a diamond indenter and measuring the size of the resulting impression. The Vickers test is known for its ability to provide precise and consistent results, making it a reliable option for evaluating the hardness of various materials, including pump impellers.

Selecting the right hardness testing method for pump impeller materials is crucial for ensuring the accuracy and reliability of the results. The hardness of these materials can impact their performance and durability, making it essential to choose a method that can provide precise measurements. By selecting the most appropriate testing method, manufacturers can make informed decisions about material selection, quality control, and process optimization.

The hardness of pump impeller materials plays a significant role in their performance and durability. Materials with higher hardness values are generally more resistant to wear, abrasion, and deformation, leading to improved longevity and efficiency of pump impellers. By accurately assessing the hardness of these materials, manufacturers can ensure that their products meet the required specifications and standards for optimal performance in various applications.

Non-destructive hardness testing methods, such as ultrasonic and electromagnetic techniques, are available for evaluating the hardness of pump impeller materials without causing any damage to the samples. These methods use sound waves or electromagnetic fields to assess the material's hardness based on its elastic properties or electrical conductivity. Non-destructive testing can be particularly useful for inspecting finished components or delicate materials that cannot undergo traditional hardness tests.

The results of hardness testing can be used to improve the design and manufacturing of pump impellers in several ways. By understanding the hardness properties of different materials, engineers can select the most suitable material for specific applications, optimize heat treatment processes to enhance hardness, and identify potential quality issues early in the production cycle. This information can help manufacturers enhance the performance, reliability, and lifespan of pump impellers, ultimately leading to better overall product quality and customer satisfaction.

When pump impellers become worn, they can often be refurbished through a process known as reconditioning or reclamation. This involves repairing any damage, restoring the impeller to its original specifications, and improving its performance. Refurbishing worn pump impellers can help extend their lifespan and save on costs compared to replacing them with new ones. However, in some cases where the impeller is severely damaged or worn beyond repair, replacement may be necessary to ensure optimal pump efficiency and functionality. It is important to consult with a professional pump technician to determine the best course of action for worn pump impellers.

Signs of misalignment in a pump shaft can include vibration, increased noise levels, overheating, premature wear on bearings, and reduced efficiency. Other indicators may include leaks, seal failures, and irregular shaft movement. It is important to regularly monitor and inspect the pump shaft for any signs of misalignment to prevent further damage and ensure optimal performance. Proper alignment of the pump shaft is crucial for maintaining the overall health and functionality of the pump system. Regular maintenance and alignment checks can help identify and address any misalignment issues before they escalate into more serious problems.

To prevent gearbox contamination from external sources, several measures can be taken. One effective method is to regularly inspect and maintain seals, gaskets, and other protective barriers to ensure they are intact and functioning properly. Additionally, implementing proper ventilation systems can help prevent the ingress of dust, dirt, and other contaminants. It is also important to keep the surrounding area clean and free of debris that could potentially enter the gearbox. Utilizing high-quality filters and breathers can further help to minimize the risk of contamination. Regularly monitoring and replacing lubricants can also play a crucial role in preventing gearbox contamination. By taking these proactive steps, the risk of external sources causing contamination in the gearbox can be significantly reduced.

Determining the appropriate pump shaft alignment tolerances involves considering factors such as shaft size, coupling type, operating speed, and alignment method. It is important to adhere to industry standards and manufacturer recommendations when setting alignment tolerances for pumps. Common alignment methods include reverse dial indicator, laser alignment, and straight edge alignment. Tolerances can vary depending on the type of pump, such as centrifugal, reciprocating, or rotary pumps. Factors like thermal growth, vibration levels, and shaft material should also be taken into account when determining alignment tolerances. Regular monitoring and adjustment of alignment tolerances can help prevent premature wear and failure of pump components.

Preventing gearbox foaming in lubricants can be achieved by implementing various measures. One effective method is to use anti-foam additives in the lubricant formulation, which help to reduce the formation of foam during operation. Additionally, ensuring that the gearbox is properly vented and that the lubricant is not overfilled can also help prevent foaming. Regularly monitoring the condition of the lubricant and changing it at recommended intervals can further prevent foaming issues. Proper maintenance of the gearbox, including checking for leaks and ensuring proper sealing, can also contribute to preventing foaming in lubricants. Overall, a combination of these measures can help maintain optimal gearbox performance and prevent foaming in lubricants.

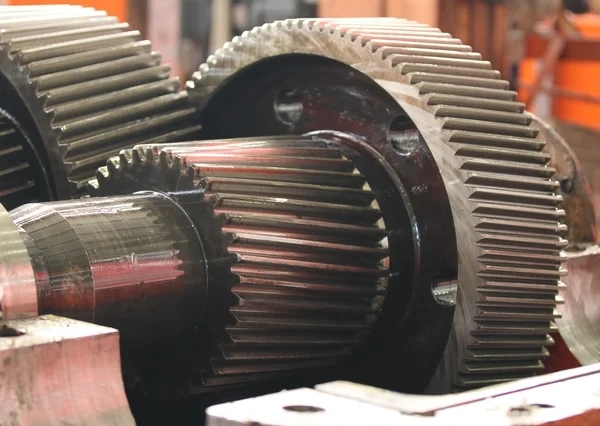

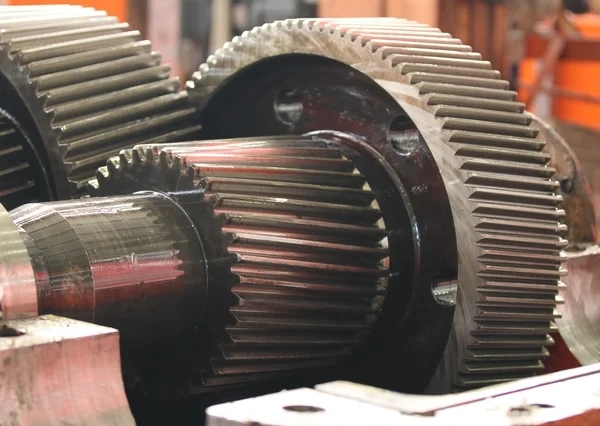

Gear tooth chipping in a gearbox can have significant implications on its performance. When gear teeth become chipped, it can lead to increased friction, vibration, and noise during operation. This can result in decreased efficiency, reduced power transmission, and potential damage to other components within the gearbox. Additionally, chipped gear teeth can cause misalignment and uneven wear, further compromising the overall performance and longevity of the gearbox. It is important to address gear tooth chipping promptly to prevent further deterioration and ensure optimal gearbox functionality. Regular maintenance, proper lubrication, and monitoring of gear tooth condition are essential to prevent issues related to chipping and maintain peak performance of the gearbox.