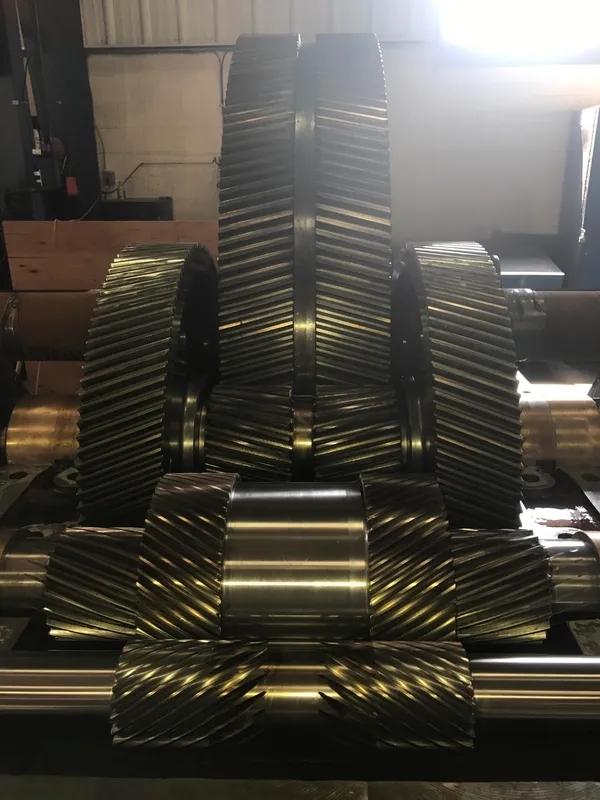

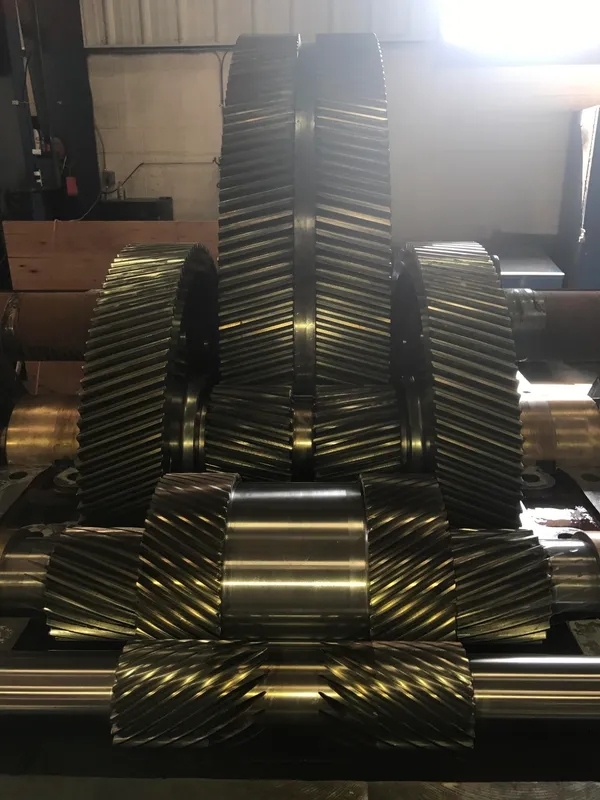

Gearbox shaft bending can be caused by various factors such as overloading, misalignment, improper installation, or wear and tear over time. These issues can lead to the shaft becoming bent, which can affect the overall performance and efficiency of the gearbox. In such cases, straightening procedures may be necessary to restore the shaft to its proper alignment and functionality.

Determining whether a gearbox shaft needs to be straightened or replaced requires a thorough inspection of the shaft for signs of bending or damage. Visual inspection, measurements, and testing for runout can help in identifying any issues with the shaft. If the shaft shows signs of bending or deformation that cannot be corrected through other means, straightening may be the best course of action.

Joy and Kevin met at a homeless shelter in Texarkana. Joy is a registered stockbroker and Kevin is a minister who says he intended to go it alone, but “God had decided to bring Joy into my life—we fell in love.” The couple assessed their strengths and recently hopped a Greyhound bus for Dallas, spending … Continued The post Dallas Public Library Introduces Homeless Community Through New Podcast appeared first on D Magazine.

Posted by on 2024-03-18

D CEO is proud to host a special Women Leaders in Law breakfast panel discussion on March 27 at the Communities Foundation of Texas. We’ll talk with accomplished attorneys about the paths they’ve chosen and the possibilities ahead. Join us as these leaders share their perspectives on the topics that are top-of-mind for women in the … Continued The post Join <I>D CEO</I> for an Inspiring Conversation with Women Leaders in Law appeared first on D Magazine.

Posted by on 2024-03-18

The Angels’ spring clubhouse is not large, closer in size to a high school locker room than a big-league dressing space. Ron Washington traverses it slowly. That might be expected of a 71-year-old man, but the new Angels manager does not putter. Clad in a red team hoodie, he’s fresh off the field, where he’d … Continued The post The Second Act of Ron Washington appeared first on D Magazine.

Posted by on 2024-03-18

When 18-year-old Melvin Hicks graduates from Moisés E. Molina High School, he wants to work in a restaurant. He’s a senior in the school’s culinary arts program, which teaches students how to cook, manage a restaurant, and develop other skills required for a career in the hospitality industry. Hicks wants to one day become an … Continued The post Dallas ISD Will Soon Have a Student-Operated Food Truck appeared first on D Magazine.

Posted by on 2024-03-18

Mavs Take Down Denver on Ridiculous Kyrie Irving Left-Handed Hook Shot. Here it is from every angle. Irving said after that he thought he’d gotten closer, but it was officially 20.1 feet, a distance from which many people couldn’t hit a regular shot in five tries. They were in position to win on that shot … Continued The post Leading Off (3/18/24) appeared first on D Magazine.

Posted by on 2024-03-18

The process of straightening a gearbox shaft typically involves the use of specialized tools and equipment such as hydraulic presses, dial indicators, and alignment fixtures. These tools are essential for applying controlled force to the shaft and monitoring its alignment during the straightening process. Proper equipment ensures that the shaft is straightened effectively without causing further damage.

Different types of gearbox shafts may require specific techniques or methods for straightening based on their design, material, and the extent of bending. For example, a hollow shaft may need internal support during straightening to prevent collapse, while a solid shaft may require different force application techniques. It is important to follow manufacturer guidelines and industry best practices when straightening gearbox shafts to ensure optimal results.

Safety precautions are crucial when performing gearbox shaft straightening procedures to prevent accidents or injuries. Proper personal protective equipment such as gloves, safety glasses, and steel-toed boots should be worn at all times. Additionally, ensuring that the work area is clear of obstructions and that the equipment is properly maintained and operated according to safety guidelines is essential for a safe working environment.

The straightening process can have a significant impact on the overall performance and lifespan of the gearbox. By correcting shaft bending and restoring proper alignment, the gearbox can operate more efficiently and smoothly, reducing wear and tear on other components. Properly straightened shafts can also help prevent future issues and prolong the lifespan of the gearbox.

When straightening gearbox shafts in different industries or applications, it is important to follow specific guidelines and standards to ensure quality and safety. Industry standards such as ISO, ANSI, or OEM specifications may provide recommendations for straightening procedures, tolerances, and quality control measures. Adhering to these guidelines can help ensure that gearbox shafts are straightened correctly and meet the required performance standards for their intended use.

To detect and rectify gear tooth misalignment, one can use various methods such as visual inspection, gear tooth contact pattern analysis, and laser alignment tools. Visual inspection involves checking for any visible signs of misalignment such as uneven wear patterns or abnormal noise during operation. Gear tooth contact pattern analysis can be done by applying a special marking compound on the gear teeth and observing the contact pattern to identify any misalignment issues. Laser alignment tools can also be used to accurately measure the alignment of gear teeth and make necessary adjustments to correct any misalignment. Additionally, adjusting the gear mesh settings, checking for proper lubrication, and ensuring proper mounting and alignment of the gear components can help rectify gear tooth misalignment issues. Regular maintenance and monitoring of gear systems can also help prevent misalignment problems in the future.

Pump wear ring clearance issues can have significant implications on the overall performance and efficiency of a pump system. When there is excessive clearance between the wear ring and the impeller, it can lead to reduced pump efficiency, increased vibration, and potential damage to the pump components. This can result in higher energy consumption, decreased flow rates, and premature wear on the pump parts. Additionally, inadequate clearance can cause cavitation, which can further deteriorate the pump performance and lead to costly repairs. Proper maintenance and monitoring of wear ring clearance is essential to ensure optimal pump operation and prevent potential issues down the line.

Preventing corrosion in gearbox components can be achieved through various measures such as applying protective coatings, using corrosion-resistant materials, implementing proper lubrication practices, maintaining a clean and dry environment, conducting regular inspections for signs of corrosion, and addressing any issues promptly. Protective coatings like zinc plating, nickel plating, or powder coating can create a barrier between the component and corrosive elements. Using materials such as stainless steel, aluminum, or titanium that are inherently resistant to corrosion can also help prevent degradation. Proper lubrication with corrosion-inhibiting oils or greases can reduce friction and moisture exposure, further protecting the components. Keeping the gearbox clean and dry can prevent the buildup of corrosive agents, while regular inspections can help identify early signs of corrosion for timely intervention. By implementing these measures, gearbox components can be safeguarded against corrosion, ensuring optimal performance and longevity.

Seals in a gearbox should be replaced periodically to ensure optimal performance and prevent leaks. The frequency of seal replacement can vary depending on factors such as the type of gearbox, operating conditions, and maintenance practices. In general, it is recommended to inspect seals regularly for signs of wear or damage, and replace them as needed. Some common indicators that seals may need to be replaced include oil leaks, excessive noise or vibration, and decreased efficiency. By replacing seals in a timely manner, gearbox components can be protected from contamination and premature wear, ultimately extending the lifespan of the equipment.

To mitigate the effects of pump erosion, various measures can be implemented. One effective strategy is to regularly inspect and maintain the pump components to ensure they are in optimal condition. Utilizing erosion-resistant materials for the pump parts, such as ceramic coatings or hardened alloys, can also help prevent erosion damage. Additionally, adjusting the pump operating conditions, such as flow rate and pressure, can reduce the impact of erosion on the pump. Installing protective measures, such as erosion shields or sacrificial coatings, can further safeguard the pump from erosion. Properly sizing the pump and ensuring proper alignment and installation can also help mitigate erosion effects. Overall, a combination of preventative maintenance, material selection, operational adjustments, and protective measures can help minimize the impact of pump erosion.