Recommended maintenance procedures for hydraulic systems in machine maintenance logs include regular inspection of hydraulic fluid levels, checking for leaks or damage in hoses and fittings, and monitoring the condition of filters and seals. It is important to follow manufacturer guidelines for fluid replacement and to use the correct type of hydraulic fluid. Additionally, maintaining proper cleanliness of the system is crucial to prevent contamination and ensure optimal performance. Regularly flushing and cleaning the system, as well as inspecting and cleaning reservoirs and tanks, can help prevent issues and extend the lifespan of hydraulic components.

Safety Considerations for Dallas-TX-Based Industrial Equipment Maintenance and Repair Companies

Lubrication schedules should be followed according to the manufacturer's recommendations for different types of machinery in machine maintenance logs. This can vary depending on factors such as the type of lubricant used, the operating conditions of the machinery, and the frequency of use. Some machinery may require daily lubrication, while others may only need lubrication every few months. It is important to regularly check and replenish lubricant levels, as well as inspect and clean lubrication points to ensure proper lubrication and prevent excessive wear and tear on moving parts.

HGR is gearing up for an electrifying online-only auction set to take place on December 5th and 6th in Birmingham, Alabama (sign up bow to bid). This two-day extravaganza promises a vast inventory reduction sale featuring an impressive catalog of over 500 lots filled with top-tier industrial equipment and machinery. For those in the... Read More... The post HGR’s Upcoming Birmingham Industrial Auction: A Treasure Trove of High-Quality Equipment – Just in Time for Section 179! appeared first on HGR Inc..

Posted by on 2023-11-20

As we approach the end of the tax year, it’s essential for businesses to explore the benefits of Section 179 of the IRS Tax Code. This provision offers a unique opportunity for businesses to save on taxes and improve cash flow by deducting the full purchase price of qualifying equipment and software. In this article,... Read More... The post Maximize 2023 Tax Benefits with Section 179: An Industrial Equipment Guide and AI Answer Bot appeared first on HGR Inc..

Posted by on 2023-11-10

HGR is excited to announce the launch of our “My Account” platform. This isn’t just a change in aesthetics but a deep-rooted enhancement, blending the functionalities you loved in “MyHGR” with additional features and a polished interface, aiming for an optimized user experience. Modernized Interface: The first thing you’ll notice is our contemporary design that... Read More... The post Step into the Future: HGR’s ‘My Account’ Takes User Experience to the Next Level! appeared first on HGR Inc..

Posted by on 2023-07-27

We’ve got some very exciting news! HGR is now an official sponsor of BattleBots. That’s right, we’re teaming up to help the top robotic competitors across the world stay battle ready. Whether you’ve tuned into an episode on Discovery channel or attended one of their live Destruct-A-Thon shows in Las Vegas, BattleBots is a... Read More... The post HGR Steps Into The Arena As Official Sponsors of BattleBots! appeared first on HGR Inc..

Posted by on 2023-04-12

Common signs of wear and tear to look out for in electrical components in machine maintenance logs include frayed or damaged wires, loose connections, overheating, and abnormal noises or smells. It is important to regularly inspect electrical components, such as switches, relays, and motors, for any signs of damage or deterioration. Additionally, monitoring voltage and current levels can help identify potential issues before they cause major problems. Any abnormalities should be addressed promptly to prevent equipment failure or electrical hazards.

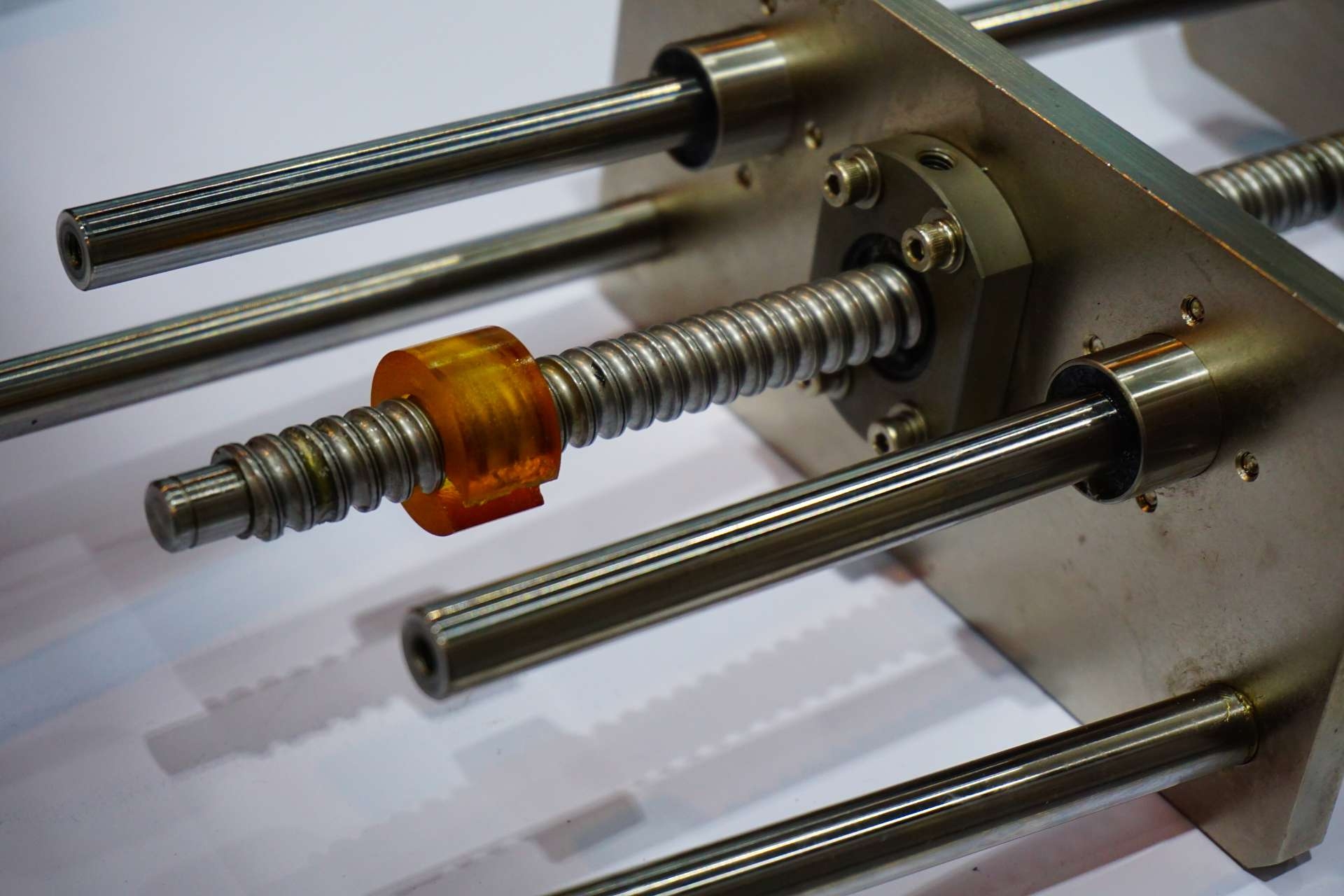

Vibration analysis can be used to detect potential issues in rotating machinery by monitoring and analyzing the vibration patterns and frequencies. By using specialized equipment, such as vibration sensors or accelerometers, vibrations can be measured and compared to established baseline levels. Any significant changes in vibration levels or frequencies can indicate potential problems, such as misalignment, unbalance, or bearing wear. Regular vibration analysis can help identify these issues early on, allowing for timely maintenance or repairs to prevent further damage or breakdowns.

Best practices for maintaining pneumatic systems in machine maintenance logs include regular inspection of air filters, regulators, and lubricators to ensure proper functioning and prevent contamination. It is important to monitor and maintain proper air pressure levels, as well as check for any leaks or damage in hoses and fittings. Regularly draining moisture from the system and cleaning or replacing filters can help prevent issues and ensure optimal performance. Additionally, following manufacturer guidelines for lubrication and using the correct type of pneumatic oil can help extend the lifespan of pneumatic components.

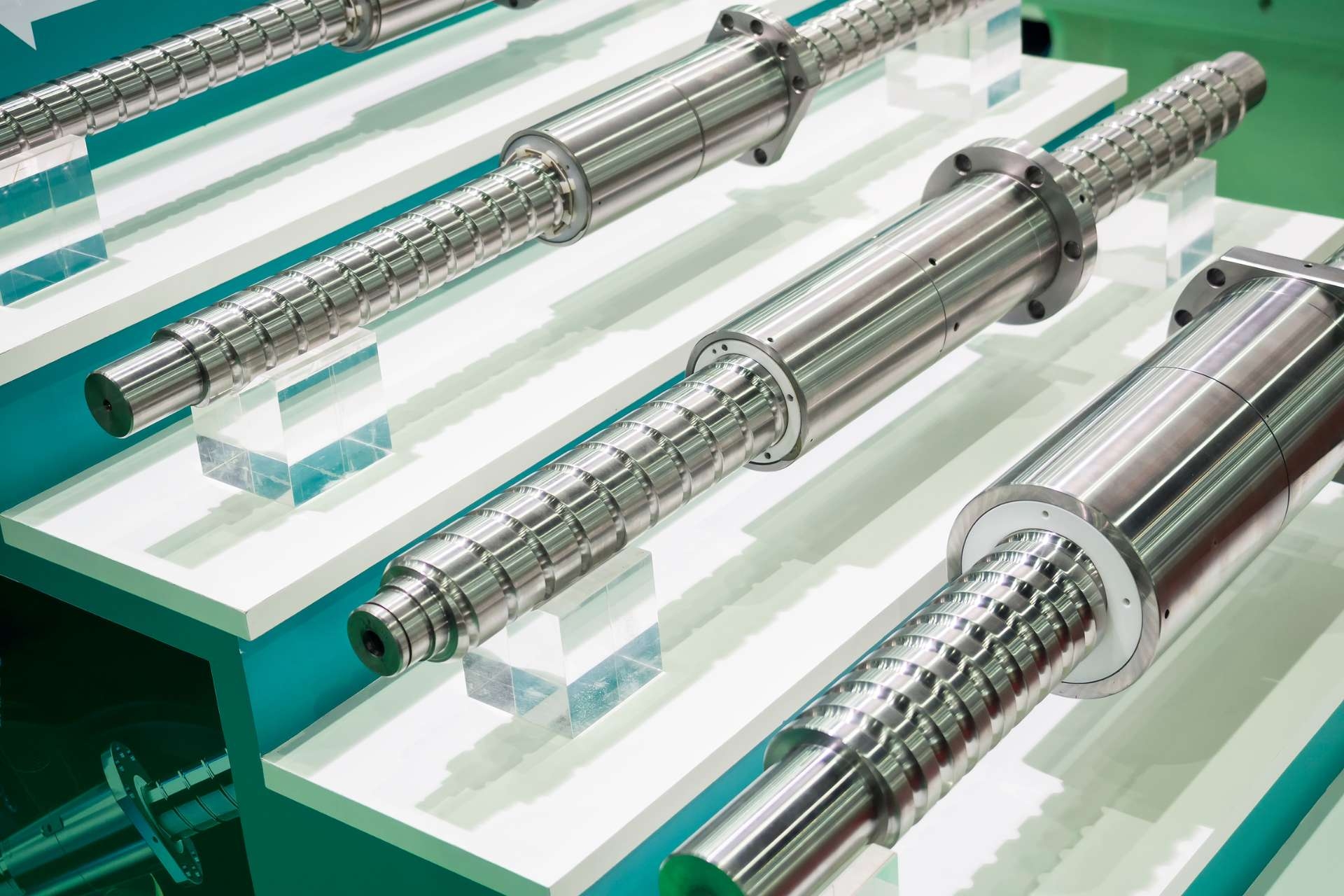

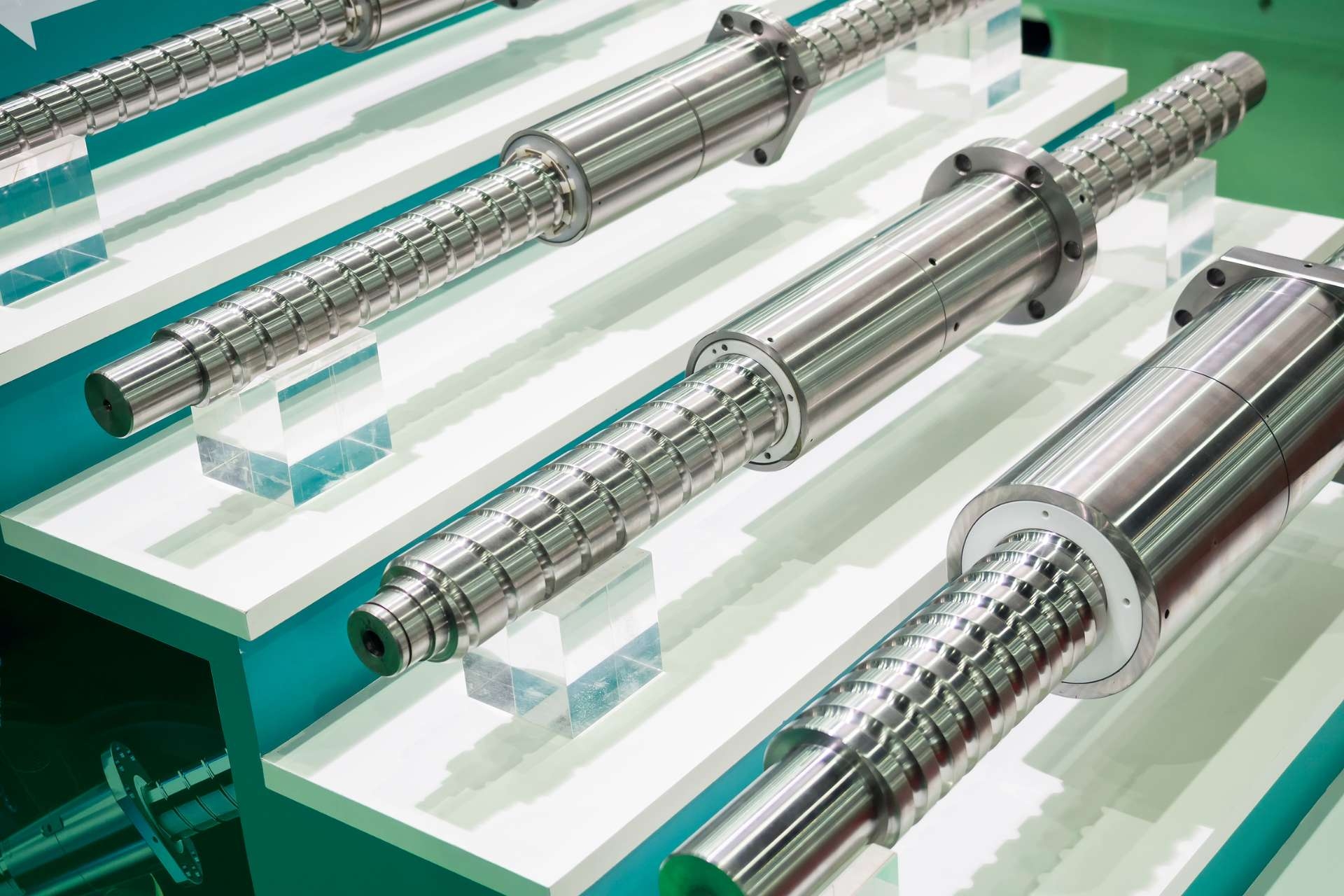

Key components to include in a preventive maintenance checklist for CNC machines in machine maintenance logs include regular inspection and cleaning of the machine's coolant system, checking and adjusting the machine's alignment and backlash, and monitoring the condition of cutting tools and tool holders. It is important to regularly inspect and clean the machine's spindle and bearings, as well as check for any abnormal noises or vibrations. Additionally, regularly calibrating and verifying the machine's accuracy and repeatability can help ensure precise and reliable operation. Following manufacturer guidelines for maintenance and lubrication is also crucial for optimal performance and longevity of CNC machines.

Thermal imaging can be utilized for predictive maintenance in machine maintenance logs by detecting abnormal heat patterns in electrical components or machinery. By using a thermal imaging camera, temperature variations can be visualized and analyzed. Any hotspots or areas of excessive heat can indicate potential issues, such as overheating, electrical faults, or mechanical problems. Regular thermal imaging inspections can help identify these issues early on, allowing for timely maintenance or repairs to prevent equipment failure or safety hazards. It is important to establish baseline temperature levels and compare them to current readings to accurately identify abnormalities.

When considering ergonomic factors for repetitive maintenance tasks, it is important to focus on the design of the work environment and tools to minimize the risk of musculoskeletal disorders. This includes ensuring that workstations are adjustable to accommodate different body sizes and postures, providing adequate support for the back, arms, and wrists, and incorporating anti-fatigue mats to reduce the impact of standing for long periods. Additionally, using power tools with vibration-dampening features, implementing job rotation to vary the types of tasks performed, and providing training on proper lifting techniques can all contribute to reducing the physical strain associated with repetitive maintenance tasks. It is also important to consider the layout of the workspace to minimize the need for excessive reaching, bending, or twisting, as well as providing adequate lighting to reduce eye strain. By addressing these ergonomic considerations, employers can help to improve the comfort, safety, and productivity of workers performing repetitive maintenance tasks.

Process safety management for equipment maintenance involves a comprehensive set of procedures and protocols aimed at ensuring the safe operation and maintenance of equipment in industrial facilities. This includes the development and implementation of maintenance plans, which outline the specific tasks, schedules, and resources required for equipment upkeep. It also involves the establishment of clear communication channels and training programs to ensure that all personnel involved in equipment maintenance are well-informed and competent in their roles. Additionally, process safety management for equipment maintenance involves the regular inspection and testing of equipment to identify any potential hazards or deficiencies, as well as the implementation of appropriate corrective actions to mitigate these risks. Furthermore, it encompasses the documentation and record-keeping of maintenance activities, including maintenance logs, work orders, and equipment history, to facilitate effective monitoring and evaluation of equipment performance and maintenance practices. Overall, process safety management for equipment maintenance is a crucial aspect of ensuring the safe and reliable operation of industrial facilities.

Personal protective devices that are commonly used for lockout/tagout procedures include safety glasses, face shields, gloves, earplugs or earmuffs, and protective clothing such as coveralls or aprons. These devices are designed to protect workers from potential hazards during the lockout/tagout process, such as flying debris, chemical splashes, excessive noise, and contact with energized equipment. Additionally, specialized personal protective equipment may be required depending on the specific task being performed, such as fall protection harnesses for working at heights or respiratory protection for working in environments with airborne contaminants. It is important for employers to provide and enforce the use of appropriate personal protective devices to ensure the safety and well-being of workers during lockout/tagout procedures.

When dealing with airborne contaminants, it is crucial to have the appropriate respiratory protection in place. This includes the use of respirators, masks, or other devices that can effectively filter out harmful particles and gases from the air. These protective measures are especially important in industries such as construction, manufacturing, healthcare, and agriculture, where workers are frequently exposed to hazardous substances. The type of respiratory protection needed may vary depending on the specific contaminants present, their concentration, and the duration of exposure. It is essential to follow industry guidelines and regulations to ensure the proper selection and use of respiratory protection equipment. This may involve considering factors such as the filtration efficiency, fit, and comfort of the respiratory devices to ensure optimal protection for individuals working in environments with airborne contaminants.

In order to mitigate noise levels in industrial environments, several measures can be implemented. Firstly, the installation of sound-absorbing materials such as acoustic panels, baffles, and curtains can effectively reduce noise propagation. Additionally, the implementation of noise barriers and enclosures can help contain and redirect noise emissions. Furthermore, the use of vibration isolation techniques, such as resilient mounts and pads, can minimize the transmission of noise through machinery and equipment. Regular maintenance and lubrication of machinery can also contribute to noise reduction by minimizing friction and mechanical vibrations. Moreover, the adoption of engineering controls, such as the use of quieter equipment and the implementation of noise control measures during the design phase, can significantly reduce noise levels in industrial settings. Lastly, the provision of personal protective equipment, such as earplugs and earmuffs, can help mitigate the impact of noise on workers' hearing health.

Proper maintenance of ventilation systems is crucial for ensuring worker safety in various industries. To maintain these systems effectively, regular inspections should be conducted to identify any potential issues or malfunctions. This includes checking for blockages, leaks, or damaged components that could compromise the system's efficiency. Additionally, cleaning and replacing filters on a routine basis is essential to prevent the buildup of dust, allergens, and other harmful particles. Adequate airflow should be maintained by regularly checking and adjusting dampers, fans, and vents. It is also important to monitor and control humidity levels to prevent the growth of mold and bacteria. By adhering to these maintenance practices, employers can create a safe and healthy working environment for their employees.