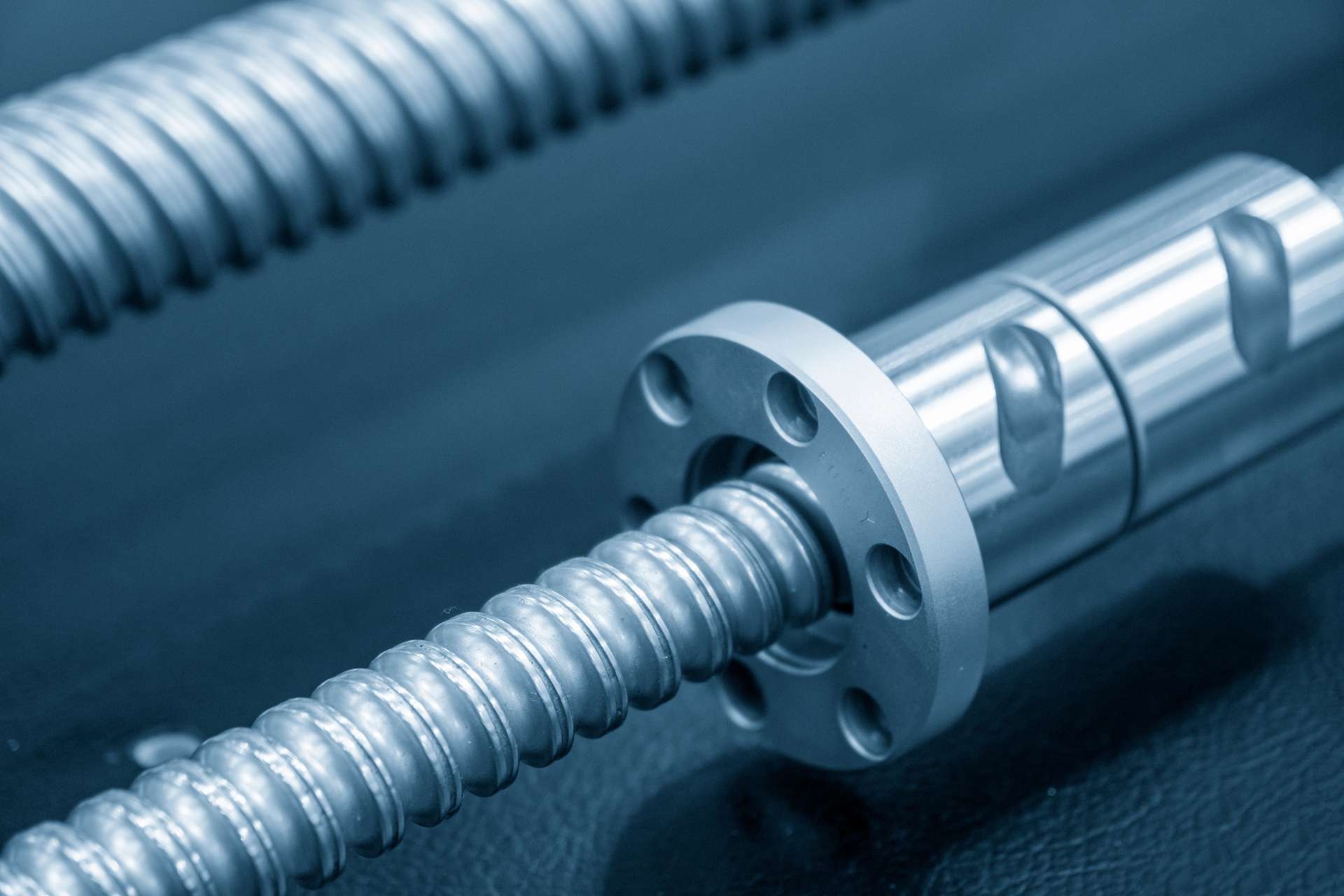

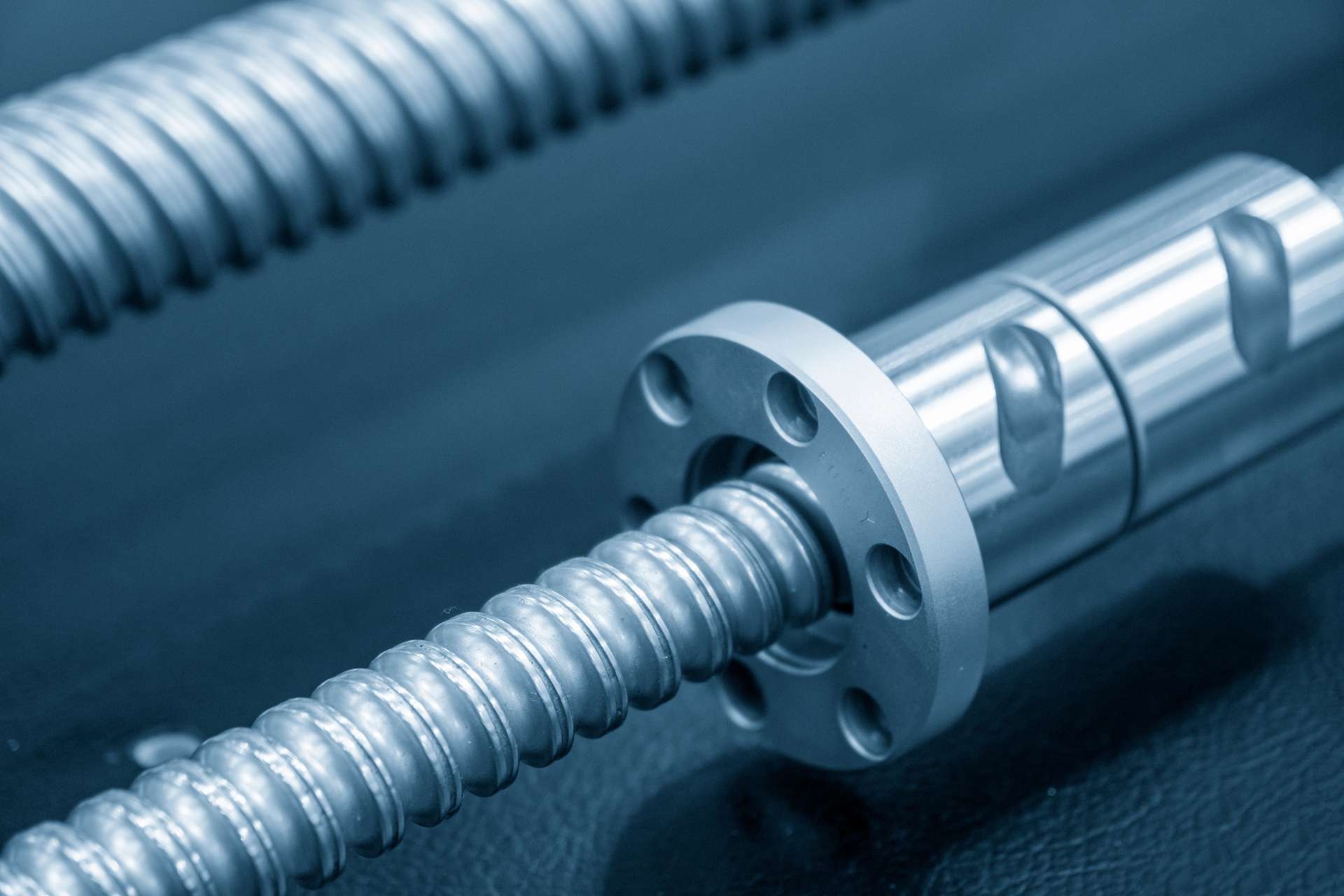

Machine guarding devices are safety mechanisms designed to protect workers from hazardous machinery in industrial settings. These devices are important because they help prevent accidents and injuries by creating a physical barrier between the worker and the machine's moving parts. They are typically made of durable materials such as metal or plastic and are installed around the dangerous areas of the machine, such as the blades or gears. Machine guarding devices are crucial in industrial settings to ensure the safety and well-being of workers and to comply with safety regulations.

Safety Considerations for Dallas-TX-Based Industrial Equipment Maintenance and Repair Companies

There are several types of machine guarding devices available in the market. One common type is fixed guards, which are permanent barriers that are securely attached to the machine. Another type is adjustable guards, which can be moved or repositioned to accommodate different sizes of materials or to access the machine for maintenance. Interlocking guards are another type, which automatically shut off the machine when the guard is opened or removed. Other types include presence-sensing devices, which use sensors to detect the presence of a worker and stop the machine, and two-hand controls, which require both hands to be engaged to operate the machine.

Giving back to the community has been a major staple of HGR’s identity since we first opened for business in 1998. This year was no different as employees from the Euclid facility gathered for their annual holiday celebration. This year HGR managed to collect and donate over 473lbs of non-perishable food items to the Euclid Hunger... Read More... The post HGR Gives Back During The Holidays! appeared first on HGR Inc..

Posted by on 2023-01-06

U.S. Inflation Slowed Sharply to 7.1% Over Past 12 Months Christopher Rugaber | Nov 13, 2022 | IEN Inflation in the United States slowed again last month in the latest sign that price increases are cooling despite the pressures they continue to inflict on American households. Economists expect the Fed to further slow its rate... Read More... The post Weekly Roundup – U.S. Inflation Slowing Down? Predictions for Manufacturing in 2023, Embracing Automation Technologies – Week of 12/12/22 appeared first on HGR Inc..

Posted by on 2022-12-15

Could These Risks Derail Your 2023 Engineering Projects? Design News | Dec 6, 2022 | Design News Design News asked Matthew Bey, senior global analyst for RANE, a risk intelligence company, about the current supply chain risks that could impact engineering projects in 2023. Around this time each year, RANE shares the key global trends and constraints that... Read More... The post Weekly Roundup – Could These Risks Derail Your 2023 Engineering Projects? 3 Critical Factors for Industry’s Future, Can Robotics Solve Labor Shortages – Week of 12/05/22 appeared first on HGR Inc..

Posted by on 2022-12-08

7 Ways Product Roadmap Management Software Helps Manufacturers Scott Dowell | Nov 11, 2022 | IEN Many global companies have learned to embrace technology over the past few years and not just by adapting to video conferencing with remote teams. Managing a product portfolio in one central location makes it easier to make adjustments, spot... Read More... The post Weekly RoundUp – Improving Roadmap Management, Is the Chip Shortage Over? What lies in Automation’s Future – Week of 11/28/22 appeared first on HGR Inc..

Posted by on 2022-12-02

Gear Up for the Grand Unveiling! Subscribe Now and Get the Inside Scoop! The clock is ticking! Are you on our email and SMS notification list yet? Brace yourself for some thrilling announcement that is coming your way soon! To get ahead of the pack, sign up for both email and SMS updates at... Read More... The post A Thrilling Surprise is on Its Way… Are You Onboard? appeared first on HGR Inc..

Posted by on 2022-12-02

Machine guarding devices play a crucial role in preventing accidents and injuries in industrial settings. By creating a physical barrier between workers and the machine's moving parts, these devices help to minimize the risk of contact with hazardous areas. They also help to prevent workers from accidentally starting or operating the machine, as many guarding devices have interlocking mechanisms that shut off the machine when the guard is opened. Additionally, machine guarding devices can help to reduce the risk of flying debris or projectiles, which can cause serious injuries. Overall, these devices are essential in maintaining a safe working environment and protecting workers from harm.

The use of machine guarding devices is regulated by various legal requirements and regulations. In many countries, there are specific standards and guidelines that dictate the design, installation, and maintenance of machine guarding devices. These regulations aim to ensure the safety of workers and prevent accidents in industrial settings. Employers are typically required to conduct risk assessments to identify potential hazards and implement appropriate guarding measures. Failure to comply with these legal requirements can result in penalties and fines. It is important for employers to stay updated with the relevant regulations and ensure that their machine guarding devices are in compliance.

When selecting and installing machine guarding devices, it is important to consider the specific requirements of different types of machinery. Each machine may have unique hazards and operating characteristics that need to be addressed. It is crucial to conduct a thorough risk assessment to identify potential hazards and determine the appropriate type of guarding device. Factors such as the size and speed of the machine, the type of material being processed, and the accessibility for maintenance should be taken into account. The guarding device should be properly installed and securely attached to the machine to ensure its effectiveness in preventing accidents and injuries.

Implementing machine guarding devices can present certain challenges or issues. One common challenge is resistance from workers who may view the guarding devices as inconvenient or hindering their productivity. It is important for employers to provide proper training and education to workers about the importance of machine guarding and the potential risks associated with not using them. Another challenge is ensuring that the guarding devices are properly maintained and inspected. Over time, guarding devices may become damaged or worn out, compromising their effectiveness. Regular inspections and maintenance should be conducted to ensure that the guarding devices are in good working condition.

Machine guarding devices require regular maintenance and inspections to ensure their effectiveness. Employers should establish a maintenance schedule to inspect and repair any damaged or worn-out guarding devices. This may involve checking for loose or missing parts, ensuring that the guards are securely attached to the machine, and replacing any damaged components. Regular inspections should also be conducted to identify any potential hazards or issues with the guarding devices. Workers should be trained to report any concerns or malfunctions with the guarding devices so that they can be promptly addressed. By maintaining and inspecting machine guarding devices, employers can ensure the ongoing safety of their workers.

Spill response teams require specialized training to effectively handle and mitigate hazardous spills. This training typically includes comprehensive instruction on spill prevention, containment, and cleanup techniques. Team members are educated on the proper use of personal protective equipment (PPE) and are trained in the identification and handling of hazardous materials. They also receive instruction on the various types of spills they may encounter, such as oil spills, chemical spills, or biological spills, and the specific protocols for each. Additionally, spill response teams often undergo training in emergency response procedures, communication protocols, and coordination with other emergency personnel. Regular drills and exercises are conducted to ensure that team members are well-prepared to respond quickly and efficiently to any spill incident.

When handling machine lubricants, it is crucial to follow certain precautions to ensure safety and optimal performance. Firstly, individuals should wear appropriate personal protective equipment (PPE) such as gloves, goggles, and protective clothing to protect themselves from potential skin contact or splashes. It is also important to handle lubricants in a well-ventilated area to avoid inhaling any fumes or vapors. Additionally, one should carefully read and follow the manufacturer's instructions and guidelines for proper storage, handling, and disposal of lubricants. This includes keeping lubricants away from heat sources, open flames, and incompatible materials. Regularly inspecting containers for leaks or damage is essential to prevent spills or accidents. Lastly, individuals should be aware of any specific hazards associated with the type of lubricant being used and take necessary precautions accordingly. By adhering to these precautions, one can ensure safe and effective handling of machine lubricants.

Heat stress in workers is monitored through various methods to ensure their safety and well-being. One common approach is the use of wearable devices that measure physiological parameters such as body temperature, heart rate, and sweat rate. These devices, equipped with sensors, provide real-time data that can be analyzed to determine if a worker is experiencing heat stress. Additionally, environmental monitoring is conducted to measure factors such as air temperature, humidity, and radiant heat. This information is combined with the physiological data to assess the risk of heat stress and make informed decisions regarding work schedules, breaks, and the provision of adequate hydration and cooling measures. Regular training and education on recognizing the signs and symptoms of heat stress also play a crucial role in monitoring and preventing its occurrence in workers.

The specific lockout/tagout procedures for pneumatic equipment involve first identifying the energy sources, such as compressed air lines, and isolating them using lockout devices. This may include shutting off the main air supply, releasing any trapped air, and ensuring that all pressure is relieved from the system. Once the energy sources are isolated, a lockout/tagout device is applied to the equipment to prevent it from being energized. This device is then labeled with a tag indicating the reason for the lockout and the name of the authorized personnel performing the procedure. Before any maintenance or servicing is performed on the pneumatic equipment, it is essential to verify that all energy sources have been effectively isolated and that the equipment is safe to work on. Additionally, proper training and communication among the maintenance team are crucial to ensure that the lockout/tagout procedures are followed accurately and consistently.

Machine-specific safety procedures require specialized training to ensure the safe operation and maintenance of specific machines. This training typically includes comprehensive instruction on the machine's specific features, functions, and potential hazards. It may cover topics such as proper machine setup, operation techniques, emergency shutdown procedures, and maintenance protocols. Additionally, training may include information on personal protective equipment (PPE) requirements, hazard identification, and risk assessment. By providing machine-specific safety training, individuals can develop the necessary knowledge and skills to operate and maintain machines safely, minimizing the risk of accidents and injuries.

Emergency lighting systems in industrial settings are required to meet certain standards and regulations to ensure the safety of workers and visitors in the event of a power outage or emergency situation. These systems must provide adequate illumination to allow for safe evacuation and must be designed to withstand harsh industrial environments. The lighting must be strategically placed to ensure that all areas of the facility are covered, including stairwells, exits, and other critical areas. Additionally, emergency lighting systems must be regularly tested and maintained to ensure that they are functioning properly and are ready to be used in the event of an emergency. Other requirements may include the use of backup power sources, such as generators or batteries, to ensure that the emergency lighting system remains operational even during a power outage. Overall, emergency lighting systems in industrial settings must be designed and installed with safety as the top priority, and must meet all relevant regulations and standards to ensure that they are effective in the event of an emergency.