To obtain a crane operator certification, there are several requirements that must be met. Firstly, the individual must be at least 18 years old and have a high school diploma or equivalent. They must also complete a crane operator training program that is accredited by the National Commission for the Certification of Crane Operators (NCCCO). Additionally, they must pass both a written and practical exam that covers topics such as crane safety, load charts, and rigging.

Safety Considerations for Dallas-TX-Based Industrial Equipment Maintenance and Repair Companies

The length of time it takes to complete a crane operator certification program can vary depending on the program and the individual's schedule. Some programs can be completed in as little as a few weeks, while others may take several months. It is important to choose a program that is accredited by the NCCCO and provides comprehensive training to ensure that the individual is fully prepared for the certification exams.

Giving back to the community has been a major staple of HGR’s identity since we first opened for business in 1998. This year was no different as employees from the Euclid facility gathered for their annual holiday celebration. This year HGR managed to collect and donate over 473lbs of non-perishable food items to the Euclid Hunger... Read More... The post HGR Gives Back During The Holidays! appeared first on HGR Inc..

Posted by on 2023-01-06

U.S. Inflation Slowed Sharply to 7.1% Over Past 12 Months Christopher Rugaber | Nov 13, 2022 | IEN Inflation in the United States slowed again last month in the latest sign that price increases are cooling despite the pressures they continue to inflict on American households. Economists expect the Fed to further slow its rate... Read More... The post Weekly Roundup – U.S. Inflation Slowing Down? Predictions for Manufacturing in 2023, Embracing Automation Technologies – Week of 12/12/22 appeared first on HGR Inc..

Posted by on 2022-12-15

Could These Risks Derail Your 2023 Engineering Projects? Design News | Dec 6, 2022 | Design News Design News asked Matthew Bey, senior global analyst for RANE, a risk intelligence company, about the current supply chain risks that could impact engineering projects in 2023. Around this time each year, RANE shares the key global trends and constraints that... Read More... The post Weekly Roundup – Could These Risks Derail Your 2023 Engineering Projects? 3 Critical Factors for Industry’s Future, Can Robotics Solve Labor Shortages – Week of 12/05/22 appeared first on HGR Inc..

Posted by on 2022-12-08

7 Ways Product Roadmap Management Software Helps Manufacturers Scott Dowell | Nov 11, 2022 | IEN Many global companies have learned to embrace technology over the past few years and not just by adapting to video conferencing with remote teams. Managing a product portfolio in one central location makes it easier to make adjustments, spot... Read More... The post Weekly RoundUp – Improving Roadmap Management, Is the Chip Shortage Over? What lies in Automation’s Future – Week of 11/28/22 appeared first on HGR Inc..

Posted by on 2022-12-02

Gear Up for the Grand Unveiling! Subscribe Now and Get the Inside Scoop! The clock is ticking! Are you on our email and SMS notification list yet? Brace yourself for some thrilling announcement that is coming your way soon! To get ahead of the pack, sign up for both email and SMS updates at... Read More... The post A Thrilling Surprise is on Its Way… Are You Onboard? appeared first on HGR Inc..

Posted by on 2022-12-02

There are several different types of crane operator certifications available, each of which is designed for a specific type of crane or job. These include mobile crane operator, tower crane operator, overhead crane operator, and articulating crane operator certifications. Each certification requires specific training and testing to ensure that the individual is qualified to operate that type of crane safely and effectively.

To become a certified crane operator, there are some medical and physical requirements that must be met. These include having good vision and hearing, as well as being able to pass a physical exam that assesses the individual's strength, flexibility, and coordination. Additionally, some certifications may have specific requirements, such as a certain level of experience or training in a related field.

A crane operator certification is generally recognized across different states and countries, although there may be some variations in the specific requirements or regulations. It is important for individuals to research the requirements in their specific location to ensure that they are fully compliant with all regulations and able to operate cranes legally and safely.

To maintain a crane operator certification, individuals must renew their certification every five years. This requires completing continuing education and training to ensure that they are up-to-date on the latest safety regulations and best practices. Additionally, they must pass a written exam to demonstrate their knowledge and skills.

There are several additional endorsements and specializations available for certified crane operators, such as the signalperson certification or the rigger certification. These endorsements require additional training and testing to ensure that the individual is qualified to perform these specialized tasks safely and effectively. By obtaining these additional certifications, crane operators can expand their skill set and increase their job opportunities.

Emergency response team members are required to possess a range of qualifications to effectively carry out their duties. These qualifications typically include a strong background in emergency management, disaster response, and crisis intervention. Additionally, team members should have extensive knowledge of emergency protocols, such as incident command systems, hazard identification, and risk assessment. Proficiency in first aid and CPR is also crucial, as is the ability to effectively communicate and coordinate with other team members and emergency personnel. Furthermore, team members should have physical stamina and the ability to remain calm and composed in high-pressure situations. Continuous training and education in areas such as emergency preparedness, hazardous materials handling, and search and rescue techniques are also essential for emergency response team members to stay up-to-date with the latest practices and procedures.

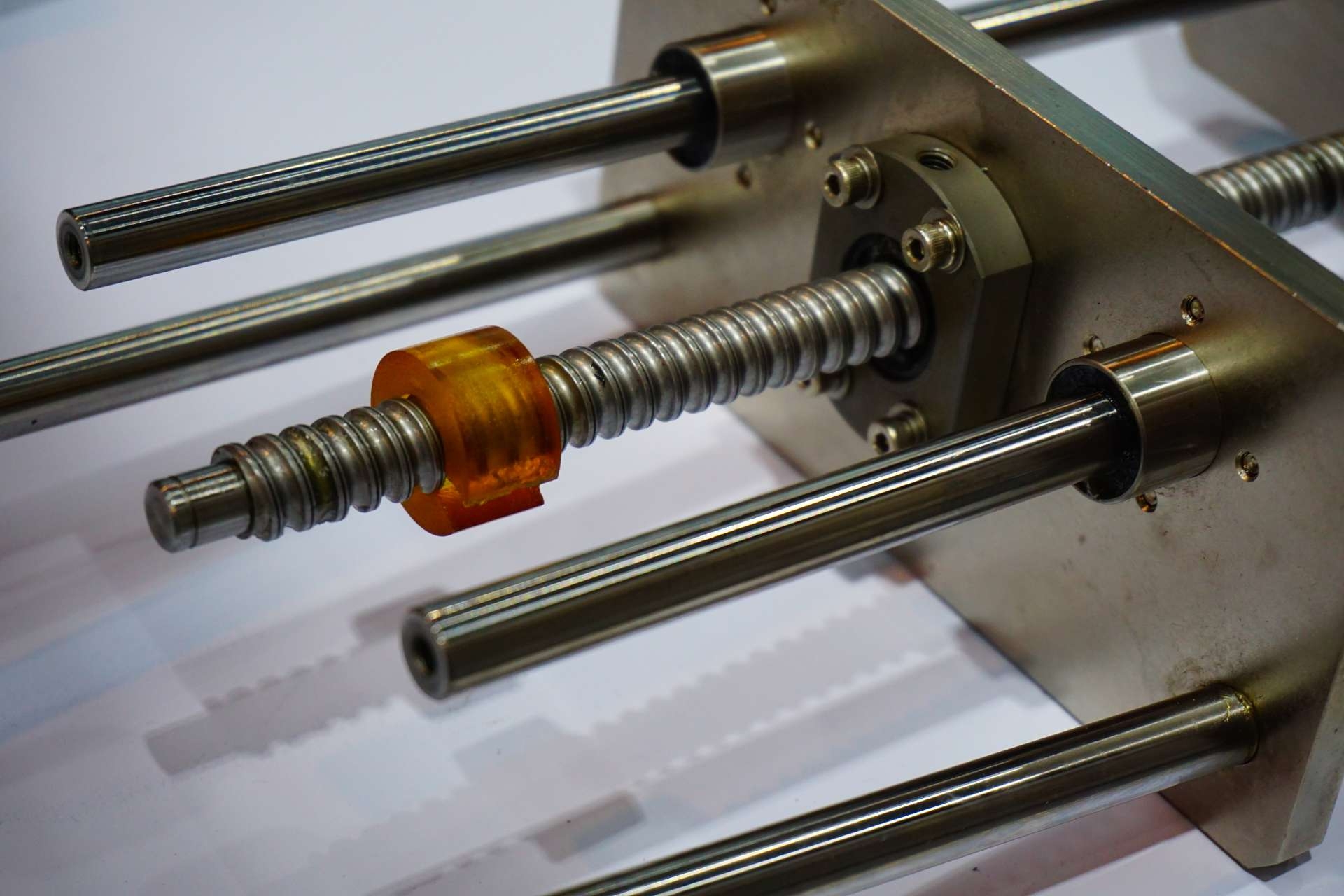

Machine lubrication should be performed on a regular basis to ensure optimal performance and longevity of the equipment. The frequency of lubrication will depend on various factors such as the type of machine, operating conditions, and the specific lubrication requirements outlined by the manufacturer. In general, it is recommended to follow a maintenance schedule that includes regular inspections and lubrication intervals to prevent excessive wear and tear, reduce friction, and minimize the risk of mechanical failures. Proper lubrication can also help to maintain the efficiency and reliability of the machine, ultimately leading to cost savings and improved productivity. It is important to use the appropriate type and amount of lubricant, as well as to follow proper application techniques to achieve the best results. Regular monitoring and documentation of lubrication activities can also help to identify any potential issues and make adjustments as needed.

Exposure limits for chemicals can be determined through a variety of methods, including toxicological studies, epidemiological data, and risk assessments. Toxicological studies involve testing the effects of a chemical on animals or cells in a laboratory setting, and can provide information on the potential health effects of exposure. Epidemiological data involves studying the health outcomes of individuals who have been exposed to a chemical in real-world settings, and can provide insight into the risks associated with exposure. Risk assessments involve evaluating the available data on a chemical, including toxicological and epidemiological studies, to determine safe exposure levels. These exposure limits are typically set by regulatory agencies, such as the Environmental Protection Agency or the Occupational Safety and Health Administration, and take into account factors such as the toxicity of the chemical, the route of exposure, and the duration and frequency of exposure.

Before using hand and power tools, it is important to perform a series of checks to ensure their safety and functionality. This includes inspecting the tool for any visible damage, such as cracks, dents, or missing parts. It is also important to check the power source and cord for any fraying or exposed wires. Additionally, the user should inspect the blades, bits, or cutting surfaces for sharpness and proper alignment. It is also crucial to ensure that all safety guards and features are in place and functioning properly. Furthermore, the user should check for any loose or damaged handles, grips, or controls. Finally, it is important to verify that the tool is appropriate for the specific task at hand and that the user is properly trained in its use. By conducting these thorough checks, the user can help prevent accidents and ensure the safe and effective use of hand and power tools.

In the event of an emergency evacuation, individuals should follow the established emergency procedures, which may include activating the fire alarm, evacuating the building via designated exit routes, assembling at a predetermined meeting point, and following the instructions of designated emergency personnel. It is important to remain calm and orderly during the evacuation process, and to assist any individuals who may require help, such as those with mobility impairments or injuries. Once outside the building, individuals should move to a safe distance and await further instructions from emergency responders. It is crucial to refrain from re-entering the building until given the all-clear by authorized personnel. Additionally, individuals should be familiar with the location of emergency exits, evacuation routes, and assembly points in advance to ensure a swift and efficient evacuation in the event of an emergency.