There are several different types of emergency communication systems available to ensure effective communication during emergencies. One type is the Emergency Alert System (EAS), which is a national public warning system that can be activated by government officials to provide emergency information to the public via television, radio, and other media outlets. Another type is the Wireless Emergency Alerts (WEA) system, which sends text-like messages to mobile devices in a specific geographic area to alert people about imminent threats or emergencies. Additionally, there are emergency communication systems specifically designed for organizations and institutions, such as mass notification systems, which use various channels like text messages, emails, and voice calls to quickly disseminate emergency information to employees or students.

Safety Considerations for Dallas-TX-Based Industrial Equipment Maintenance and Repair Companies

Emergency communication systems ensure effective communication during emergencies by utilizing various strategies and technologies. Firstly, they often employ multiple communication channels to reach a wide audience, such as text messages, phone calls, emails, and social media notifications. This helps to ensure that people receive the emergency information through their preferred method of communication. Secondly, these systems often have the capability to send out mass notifications simultaneously, allowing for quick and efficient dissemination of information. Additionally, emergency communication systems may have features like pre-recorded messages or templates that can be customized and activated with just a few clicks, saving valuable time during critical situations.

We heard your feedback and HGR is here to make storing your equipment much easier our new and improved storage policy update. HGR is proud to announce that our new storage policy update is here to make it more cost efficient for our customers. Starting this month, HGR will bill out storage fees on... Read More... The post We Heard You! Check Out Our Improved Storage Policy appeared first on HGR Inc..

Posted by on 2023-02-02

Giving back to the community has been a major staple of HGR’s identity since we first opened for business in 1998. This year was no different as employees from the Euclid facility gathered for their annual holiday celebration. This year HGR managed to collect and donate over 473lbs of non-perishable food items to the Euclid Hunger... Read More... The post HGR Gives Back During The Holidays! appeared first on HGR Inc..

Posted by on 2023-01-06

U.S. Inflation Slowed Sharply to 7.1% Over Past 12 Months Christopher Rugaber | Nov 13, 2022 | IEN Inflation in the United States slowed again last month in the latest sign that price increases are cooling despite the pressures they continue to inflict on American households. Economists expect the Fed to further slow its rate... Read More... The post Weekly Roundup – U.S. Inflation Slowing Down? Predictions for Manufacturing in 2023, Embracing Automation Technologies – Week of 12/12/22 appeared first on HGR Inc..

Posted by on 2022-12-15

Could These Risks Derail Your 2023 Engineering Projects? Design News | Dec 6, 2022 | Design News Design News asked Matthew Bey, senior global analyst for RANE, a risk intelligence company, about the current supply chain risks that could impact engineering projects in 2023. Around this time each year, RANE shares the key global trends and constraints that... Read More... The post Weekly Roundup – Could These Risks Derail Your 2023 Engineering Projects? 3 Critical Factors for Industry’s Future, Can Robotics Solve Labor Shortages – Week of 12/05/22 appeared first on HGR Inc..

Posted by on 2022-12-08

When choosing an emergency communication system, there are several key features to consider. Firstly, it is important to assess the system's reliability and redundancy. This includes evaluating the system's uptime, backup power sources, and the ability to handle high volumes of messages during emergencies. Secondly, the system should have the capability to integrate with other emergency response systems, such as fire alarms or security systems, to provide a comprehensive emergency communication solution. Additionally, the system should have a user-friendly interface that allows for easy message creation and distribution. It is also important to consider the system's scalability, as the organization's needs may change over time. Finally, it is crucial to ensure that the system complies with relevant regulations and standards, such as the Federal Communications Commission (FCC) guidelines for emergency alerts.

Emergency communication systems can integrate with other emergency response systems to enhance overall emergency preparedness and response. For example, they can integrate with fire alarm systems to automatically trigger emergency notifications when a fire alarm is activated. Similarly, they can integrate with security systems to send out alerts and instructions in the event of a security breach or threat. Integration with weather monitoring systems can also enable the system to automatically send out weather-related alerts and warnings. These integrations help to streamline the emergency response process and ensure that relevant information is communicated to the appropriate parties in a timely manner.

Implementing and maintaining emergency communication systems can present several challenges. One common challenge is ensuring that the system reaches all intended recipients, especially in large organizations or densely populated areas. This may require the use of multiple communication channels and the ability to target specific groups or locations. Another challenge is keeping the system up to date and compatible with evolving technologies. Regular maintenance and updates are necessary to ensure that the system remains reliable and effective. Additionally, training personnel to effectively use the system and respond appropriately during emergencies can be a challenge. Ongoing training and drills are essential to ensure that personnel are familiar with the system and know how to use it effectively in high-stress situations.

Emergency communication systems are designed to handle different types of emergencies, including natural disasters and terrorist attacks. In the case of natural disasters, such as hurricanes or earthquakes, these systems can send out alerts and warnings to affected areas, providing information on evacuation routes, shelter locations, and safety precautions. They can also provide updates on the status of the emergency and any ongoing relief efforts. In the case of terrorist attacks, emergency communication systems can be used to alert the public about the threat, provide instructions on how to stay safe, and disseminate information about the ongoing situation. These systems play a crucial role in keeping the public informed and helping them make informed decisions during emergencies.

Training personnel to use emergency communication systems effectively is essential for ensuring a coordinated and efficient response during emergencies. Best practices for training include providing comprehensive training sessions that cover the system's features, functionality, and protocols. This can include hands-on exercises and simulations to familiarize personnel with the system and its capabilities. Regular refresher training sessions should also be conducted to reinforce knowledge and skills. It is important to involve key personnel from different departments or units in the training process to ensure a holistic understanding of the system and its integration with other emergency response systems. Additionally, providing clear guidelines and protocols for using the system during emergencies can help personnel respond effectively and make informed decisions.

Crane operators are required to obtain certain certifications in order to ensure their competence and safety in operating cranes. One of the most important certifications for crane operators is the National Commission for the Certification of Crane Operators (NCCCO) certification. This certification is widely recognized and demonstrates that the operator has met the industry's standards for knowledge and skills. Additionally, crane operators may also need to obtain specific certifications for different types of cranes they operate, such as mobile cranes, tower cranes, or overhead cranes. These certifications typically involve both written and practical exams to assess the operator's understanding of crane operations, safety procedures, and ability to handle different loads and environments. Other certifications that may be required include Occupational Safety and Health Administration (OSHA) certifications, which focus on safety regulations and practices, and certifications related to specific industries or job sites, such as construction or oil and gas. Overall, obtaining the necessary certifications is crucial for crane operators to demonstrate their expertise and ensure the safe and efficient operation of cranes.

A comprehensive respiratory protection program typically includes several key components to ensure the safety and well-being of workers. These components may include a thorough assessment of workplace hazards, such as airborne contaminants or oxygen-deficient environments, to determine the appropriate level of respiratory protection needed. The program may also involve the selection and use of appropriate respiratory protective equipment, such as respirators or masks, based on the identified hazards. Training and education on the proper use, maintenance, and limitations of respiratory protective equipment are crucial aspects of the program. Fit testing and medical evaluations may be conducted to ensure that the selected respiratory protective equipment fits properly and does not pose any health risks to the wearer. Additionally, regular inspections, maintenance, and cleaning of respiratory protective equipment are essential to ensure their effectiveness. Finally, a respiratory protection program should include procedures for monitoring and evaluating the program's effectiveness, as well as protocols for addressing any deficiencies or incidents that may occur.

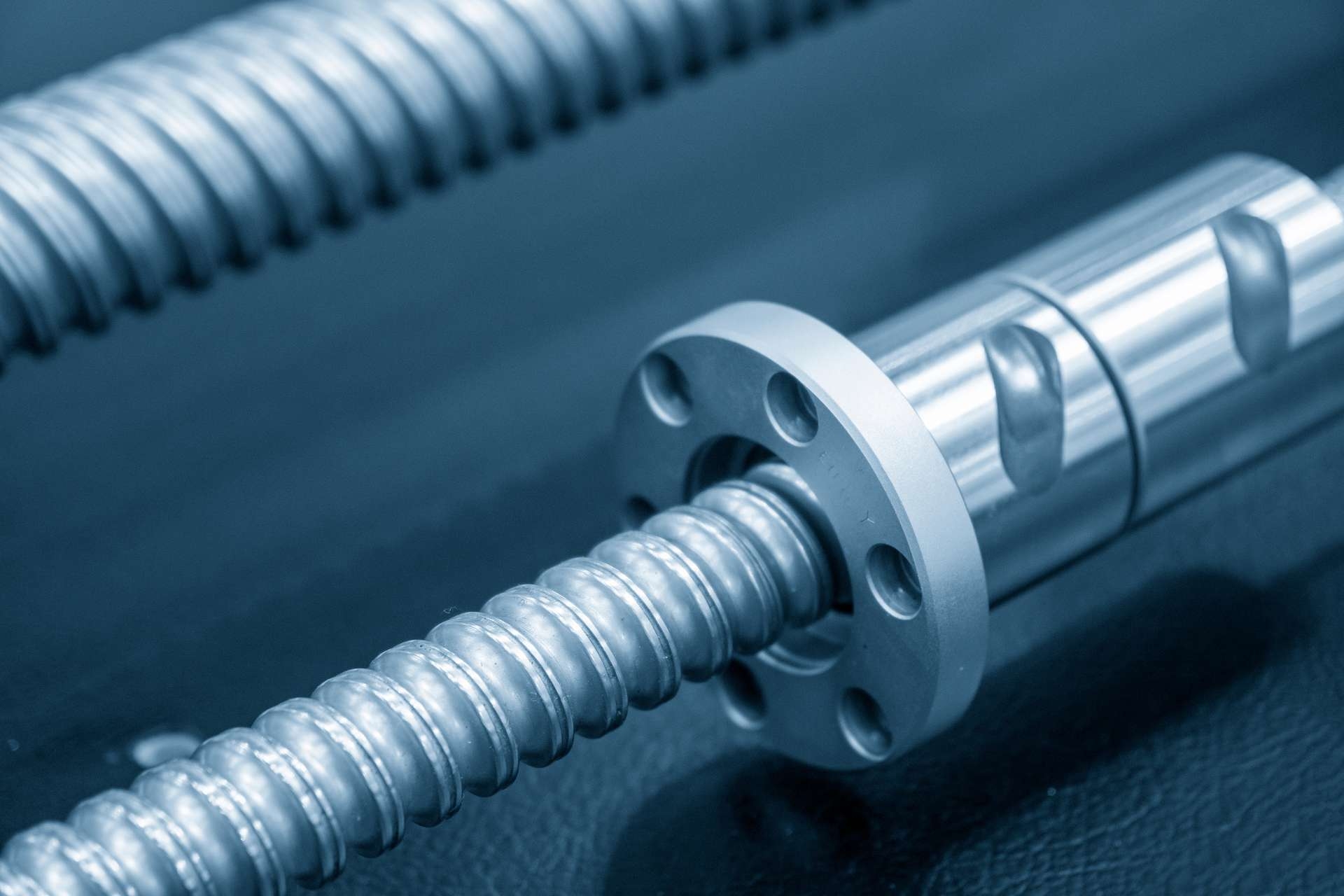

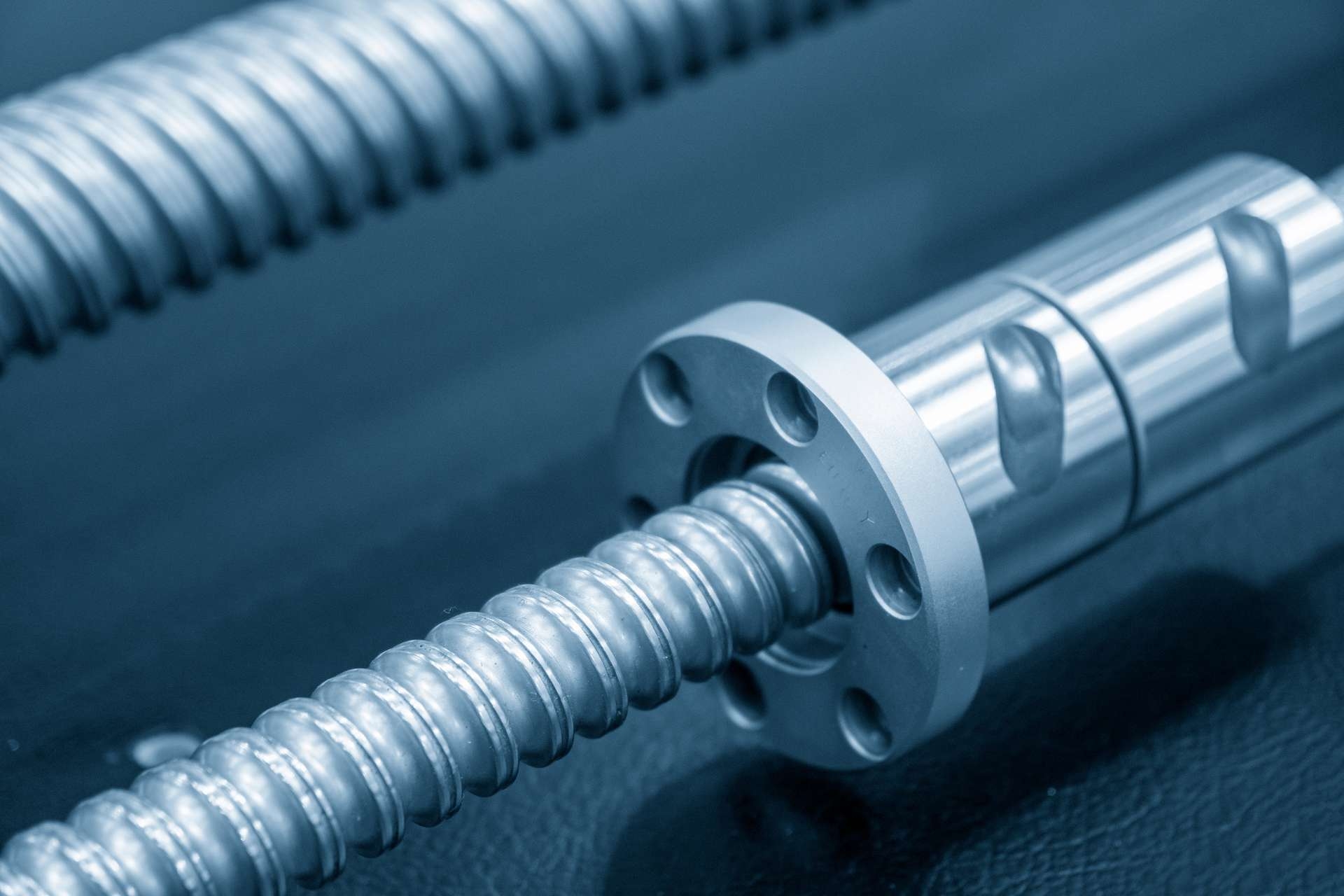

When lubricating equipment, it is important to follow certain precautions to ensure optimal performance and safety. Firstly, it is crucial to select the appropriate lubricant for the specific equipment and its intended use. This involves considering factors such as viscosity, temperature range, and compatibility with the materials involved. Additionally, the equipment should be thoroughly cleaned and free from any debris or contaminants before applying the lubricant. This helps to prevent any potential damage or interference with the lubrication process. It is also essential to follow the manufacturer's guidelines and recommendations regarding the frequency and quantity of lubricant application. Over-lubrication can lead to excessive heat generation and component wear, while under-lubrication can result in increased friction and premature failure. Furthermore, proper storage and handling of lubricants are important to maintain their effectiveness. They should be stored in a cool, dry place away from direct sunlight and sources of ignition. Lastly, personal protective equipment, such as gloves and safety glasses, should be worn to protect against any potential hazards during the lubrication process. By adhering to these precautions, one can ensure the smooth operation and longevity of the equipment.

During repairs, it is crucial to handle asbestos-containing materials with utmost care and follow proper procedures to ensure the safety of everyone involved. Firstly, it is important to identify and assess the presence of asbestos in the materials, using techniques such as visual inspection, sampling, and laboratory analysis. Once confirmed, the materials should be handled by trained professionals who have expertise in asbestos abatement. They should wear appropriate personal protective equipment (PPE) such as respirators, gloves, and coveralls to minimize the risk of asbestos exposure. The materials should be wetted down to prevent the release of asbestos fibers into the air and then carefully removed using specialized tools and techniques. All debris and waste should be sealed in leak-tight containers and labeled as asbestos-containing materials for proper disposal. Regular air monitoring should be conducted to ensure that the area is safe and free from asbestos fibers. By following these meticulous procedures, the handling of asbestos-containing materials during repairs can be done safely and effectively.

The confined space entry requirements for working in a chemical tank are governed by strict regulations and guidelines to ensure the safety of workers. These requirements include conducting a thorough risk assessment to identify potential hazards such as toxic gases, flammable materials, and oxygen deficiency. Adequate ventilation systems must be in place to maintain a safe atmosphere within the tank. Workers must be trained on the proper use of personal protective equipment (PPE) such as respirators, protective clothing, and gas detectors. Additionally, a permit-to-work system may be implemented to control access to the tank and ensure that all necessary precautions have been taken before entry. Regular monitoring of the tank's atmosphere and continuous communication with workers inside the tank are also essential to prevent accidents and respond promptly to any emergencies.

Confined spaces should be ventilated during maintenance by using mechanical ventilation systems such as blowers, fans, or ducts to ensure the circulation of fresh air. It is important to monitor the air quality and use gas detection equipment to detect any hazardous gases or fumes present in the confined space. Additionally, proper ventilation should be maintained throughout the duration of the maintenance work to prevent the buildup of toxic or flammable gases. Adequate ventilation can help to mitigate the risk of asphyxiation, fire, or explosion in confined spaces, ensuring the safety of workers and preventing potential accidents. It is also essential to follow OSHA regulations and industry standards for confined space ventilation to ensure compliance and safety.

When handling batteries during maintenance, it is crucial to take certain precautions to ensure safety and prevent accidents. Firstly, it is important to wear appropriate personal protective equipment (PPE) such as gloves, safety goggles, and protective clothing to protect against any potential chemical spills or splashes. Additionally, one should ensure that the work area is well-ventilated to minimize the risk of inhaling any harmful fumes or gases emitted by the batteries. It is also advisable to have a fire extinguisher nearby in case of any fire-related incidents. Furthermore, one should be cautious while handling batteries to avoid any physical damage or short-circuiting, as this can lead to leakage of corrosive substances or even explosions. Proper training and knowledge of battery handling procedures are essential to minimize risks and ensure the safe maintenance of batteries.