When working with live wires, it is crucial to follow key electrical safety practices to prevent accidents and injuries. This includes wearing appropriate personal protective equipment such as insulated gloves and safety goggles, ensuring that the power source is turned off before working on the wires, using insulated tools, and keeping a safe distance from the live wires. Additionally, it is important to regularly inspect the wires for any signs of damage or wear and to follow proper lockout/tagout procedures to prevent unexpected energization.

To ensure electrical safety when using power tools, it is important to inspect the tools for any damage or defects before use. Always use tools that are properly grounded or double insulated, and never remove or bypass safety features such as guards or shields. It is also important to use the right tool for the job and to avoid using damaged or frayed cords. Additionally, following proper operating procedures and using the appropriate personal protective equipment can help prevent electrical accidents while using power tools.

We heard your feedback and HGR is here to make storing your equipment much easier our new and improved storage policy update. HGR is proud to announce that our new storage policy update is here to make it more cost efficient for our customers. Starting this month, HGR will bill out storage fees on... Read More... The post We Heard You! Check Out Our Improved Storage Policy appeared first on HGR Inc..

Posted by on 2023-02-02

Giving back to the community has been a major staple of HGR’s identity since we first opened for business in 1998. This year was no different as employees from the Euclid facility gathered for their annual holiday celebration. This year HGR managed to collect and donate over 473lbs of non-perishable food items to the Euclid Hunger... Read More... The post HGR Gives Back During The Holidays! appeared first on HGR Inc..

Posted by on 2023-01-06

U.S. Inflation Slowed Sharply to 7.1% Over Past 12 Months Christopher Rugaber | Nov 13, 2022 | IEN Inflation in the United States slowed again last month in the latest sign that price increases are cooling despite the pressures they continue to inflict on American households. Economists expect the Fed to further slow its rate... Read More... The post Weekly Roundup – U.S. Inflation Slowing Down? Predictions for Manufacturing in 2023, Embracing Automation Technologies – Week of 12/12/22 appeared first on HGR Inc..

Posted by on 2022-12-15

Could These Risks Derail Your 2023 Engineering Projects? Design News | Dec 6, 2022 | Design News Design News asked Matthew Bey, senior global analyst for RANE, a risk intelligence company, about the current supply chain risks that could impact engineering projects in 2023. Around this time each year, RANE shares the key global trends and constraints that... Read More... The post Weekly Roundup – Could These Risks Derail Your 2023 Engineering Projects? 3 Critical Factors for Industry’s Future, Can Robotics Solve Labor Shortages – Week of 12/05/22 appeared first on HGR Inc..

Posted by on 2022-12-08

When working on electrical equipment, there are precautions that should be taken to prevent electrical shocks. This includes ensuring that the equipment is properly de-energized before starting any work, using insulated tools and wearing appropriate personal protective equipment, and following proper lockout/tagout procedures. It is also important to be aware of the potential hazards and to work in a methodical and cautious manner to prevent accidental contact with live parts.

Recommended safety measures for preventing electrical fires include regular inspection and maintenance of electrical systems and equipment, using the correct fuses and circuit breakers, and avoiding overloading circuits. It is also important to keep flammable materials away from electrical equipment, to use electrical equipment that is approved by a recognized testing laboratory, and to have a fire extinguisher readily available in case of an electrical fire.

Safety Considerations for Dallas-TX-Based Industrial Equipment Maintenance and Repair Companies

When handling and storing electrical equipment and cords, it is important to do so safely to prevent accidents and damage. This includes properly coiling and storing cords to prevent tripping hazards and damage, using cord protectors or covers when cords need to cross walkways, and avoiding overloading outlets or power strips. It is also important to inspect cords and equipment for any signs of damage or wear and to replace or repair as needed.

When working in wet or damp conditions, it is important to follow important safety guidelines to prevent electrical accidents. This includes using ground fault circuit interrupters (GFCIs) to protect against electric shock, using tools and equipment that are designed for wet conditions, and avoiding contact with electrical equipment with wet hands or while standing in water. It is also important to be aware of the potential hazards and to take extra precautions to prevent electrical accidents in wet or damp environments.

Potential hazards of using extension cords include overloading circuits, creating trip hazards, and using damaged or improperly rated cords. To mitigate these hazards, it is important to use extension cords that are rated for the intended use, to avoid daisy-chaining multiple cords together, and to inspect cords for any signs of damage or wear. Additionally, it is important to use extension cords with built-in circuit breakers or surge protectors to prevent overloading and to avoid running cords under carpets or through doorways where they can be damaged.

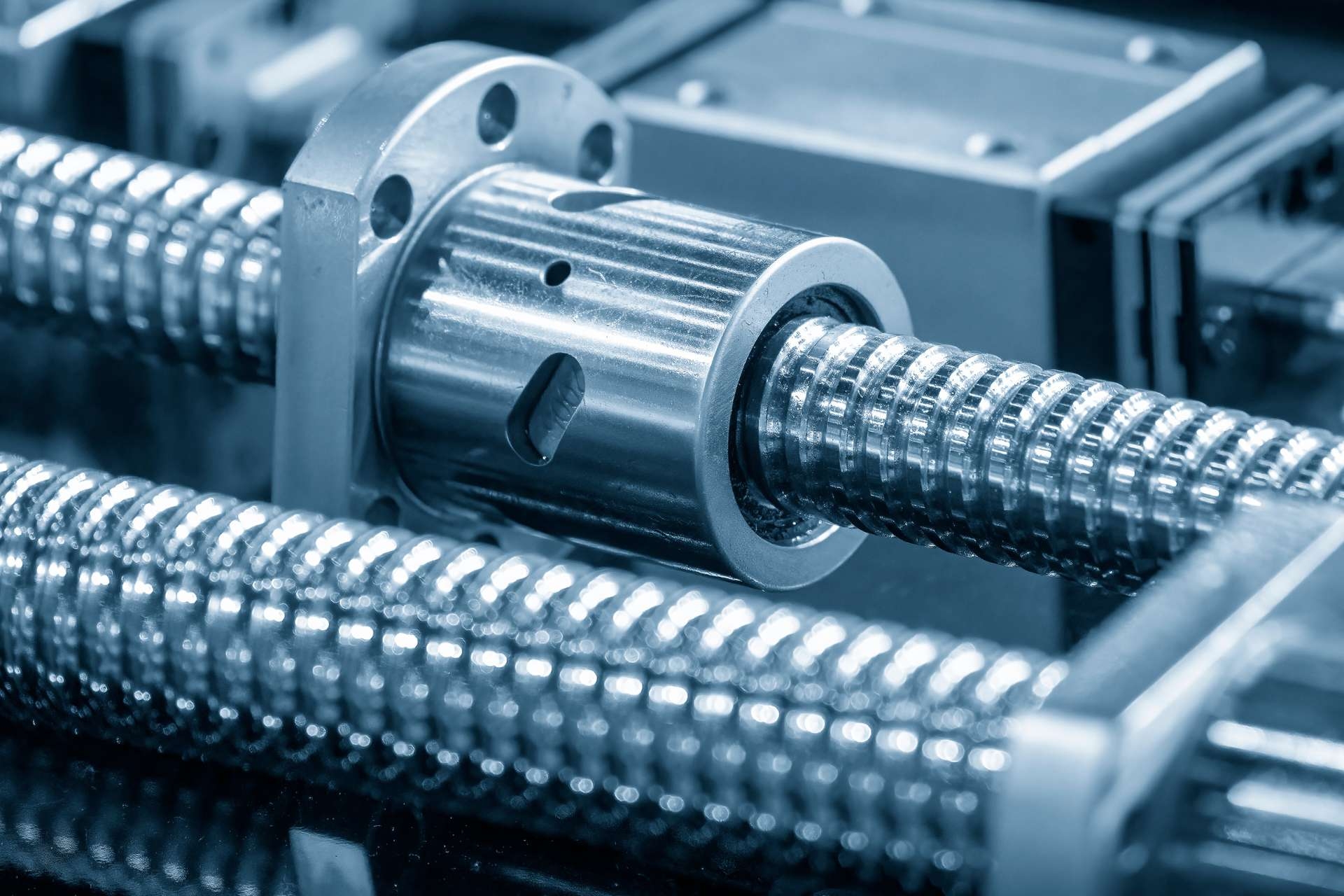

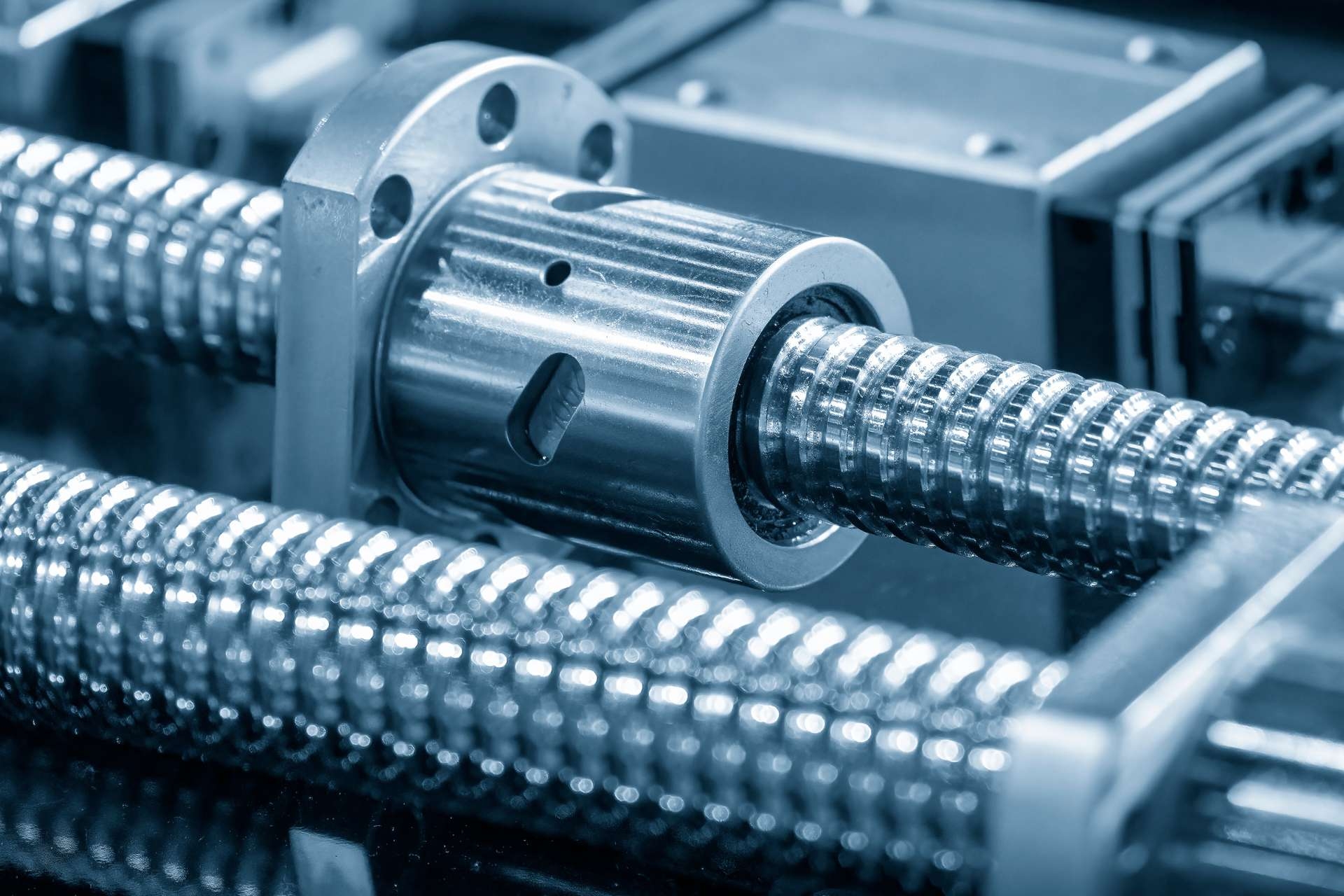

Machine lubrication should be performed on a regular basis to ensure optimal performance and longevity of the equipment. The frequency of lubrication will depend on various factors such as the type of machine, operating conditions, and the specific lubrication requirements outlined by the manufacturer. In general, it is recommended to follow a maintenance schedule that includes regular inspections and lubrication intervals to prevent excessive wear and tear, reduce friction, and minimize the risk of mechanical failures. Proper lubrication can also help to maintain the efficiency and reliability of the machine, ultimately leading to cost savings and improved productivity. It is important to use the appropriate type and amount of lubricant, as well as to follow proper application techniques to achieve the best results. Regular monitoring and documentation of lubrication activities can also help to identify any potential issues and make adjustments as needed.

Exposure limits for chemicals can be determined through a variety of methods, including toxicological studies, epidemiological data, and risk assessments. Toxicological studies involve testing the effects of a chemical on animals or cells in a laboratory setting, and can provide information on the potential health effects of exposure. Epidemiological data involves studying the health outcomes of individuals who have been exposed to a chemical in real-world settings, and can provide insight into the risks associated with exposure. Risk assessments involve evaluating the available data on a chemical, including toxicological and epidemiological studies, to determine safe exposure levels. These exposure limits are typically set by regulatory agencies, such as the Environmental Protection Agency or the Occupational Safety and Health Administration, and take into account factors such as the toxicity of the chemical, the route of exposure, and the duration and frequency of exposure.

Before using hand and power tools, it is important to perform a series of checks to ensure their safety and functionality. This includes inspecting the tool for any visible damage, such as cracks, dents, or missing parts. It is also important to check the power source and cord for any fraying or exposed wires. Additionally, the user should inspect the blades, bits, or cutting surfaces for sharpness and proper alignment. It is also crucial to ensure that all safety guards and features are in place and functioning properly. Furthermore, the user should check for any loose or damaged handles, grips, or controls. Finally, it is important to verify that the tool is appropriate for the specific task at hand and that the user is properly trained in its use. By conducting these thorough checks, the user can help prevent accidents and ensure the safe and effective use of hand and power tools.

In the event of an emergency evacuation, individuals should follow the established emergency procedures, which may include activating the fire alarm, evacuating the building via designated exit routes, assembling at a predetermined meeting point, and following the instructions of designated emergency personnel. It is important to remain calm and orderly during the evacuation process, and to assist any individuals who may require help, such as those with mobility impairments or injuries. Once outside the building, individuals should move to a safe distance and await further instructions from emergency responders. It is crucial to refrain from re-entering the building until given the all-clear by authorized personnel. Additionally, individuals should be familiar with the location of emergency exits, evacuation routes, and assembly points in advance to ensure a swift and efficient evacuation in the event of an emergency.

An electrical hazard analysis involves a comprehensive assessment of potential risks and dangers associated with electrical systems and equipment. This analysis typically includes the identification and evaluation of electrical hazards such as electrical shock, arc flash, and electrical fires. It involves examining the electrical infrastructure, equipment, and processes to identify potential hazards and determine the likelihood and severity of potential incidents. The analysis may also involve reviewing safety procedures, training programs, and maintenance practices to ensure compliance with relevant regulations and standards. Additionally, it may include the development of mitigation strategies and recommendations to minimize or eliminate identified hazards. Overall, an electrical hazard analysis aims to enhance safety and prevent accidents in electrical systems and environments.