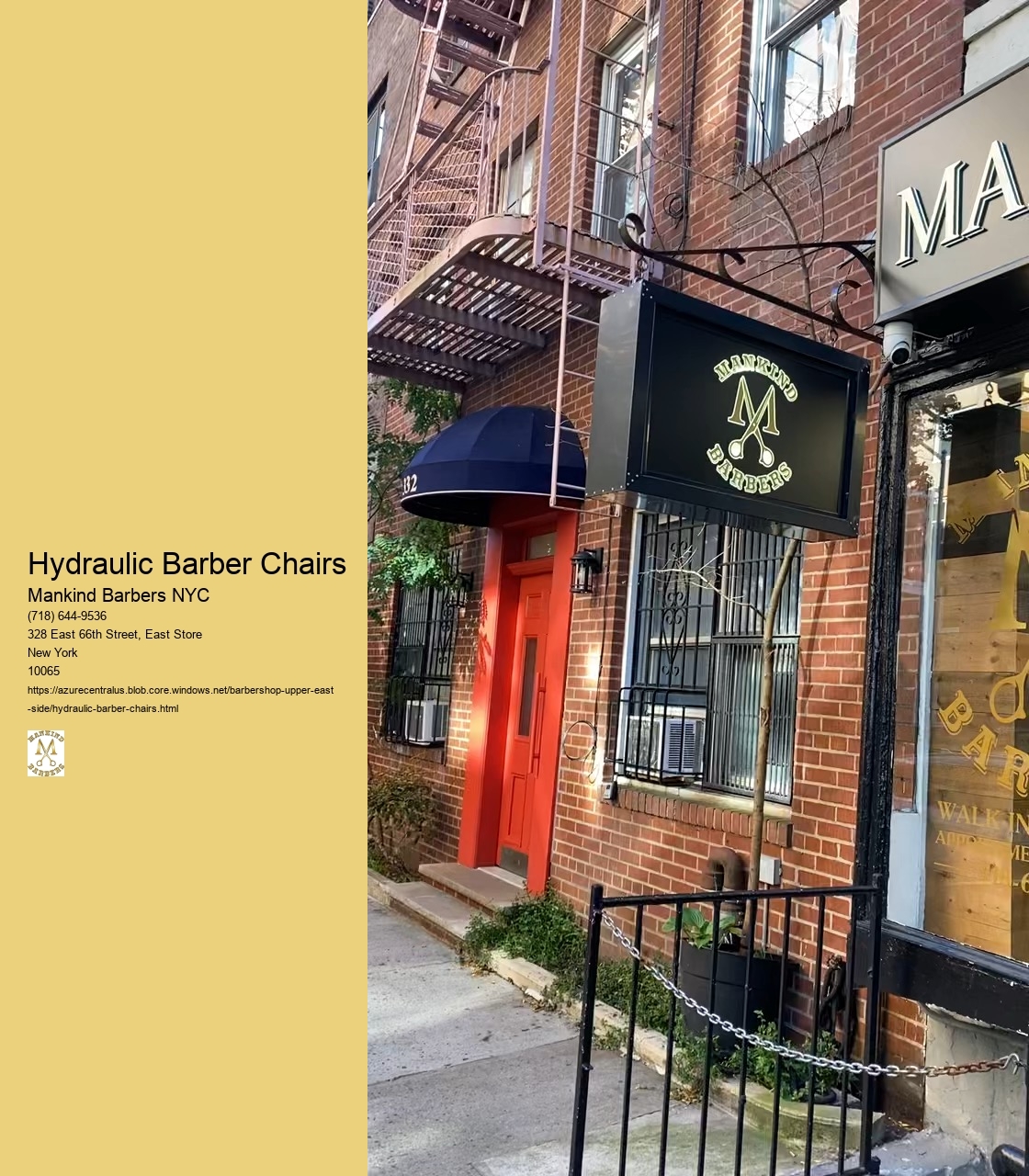

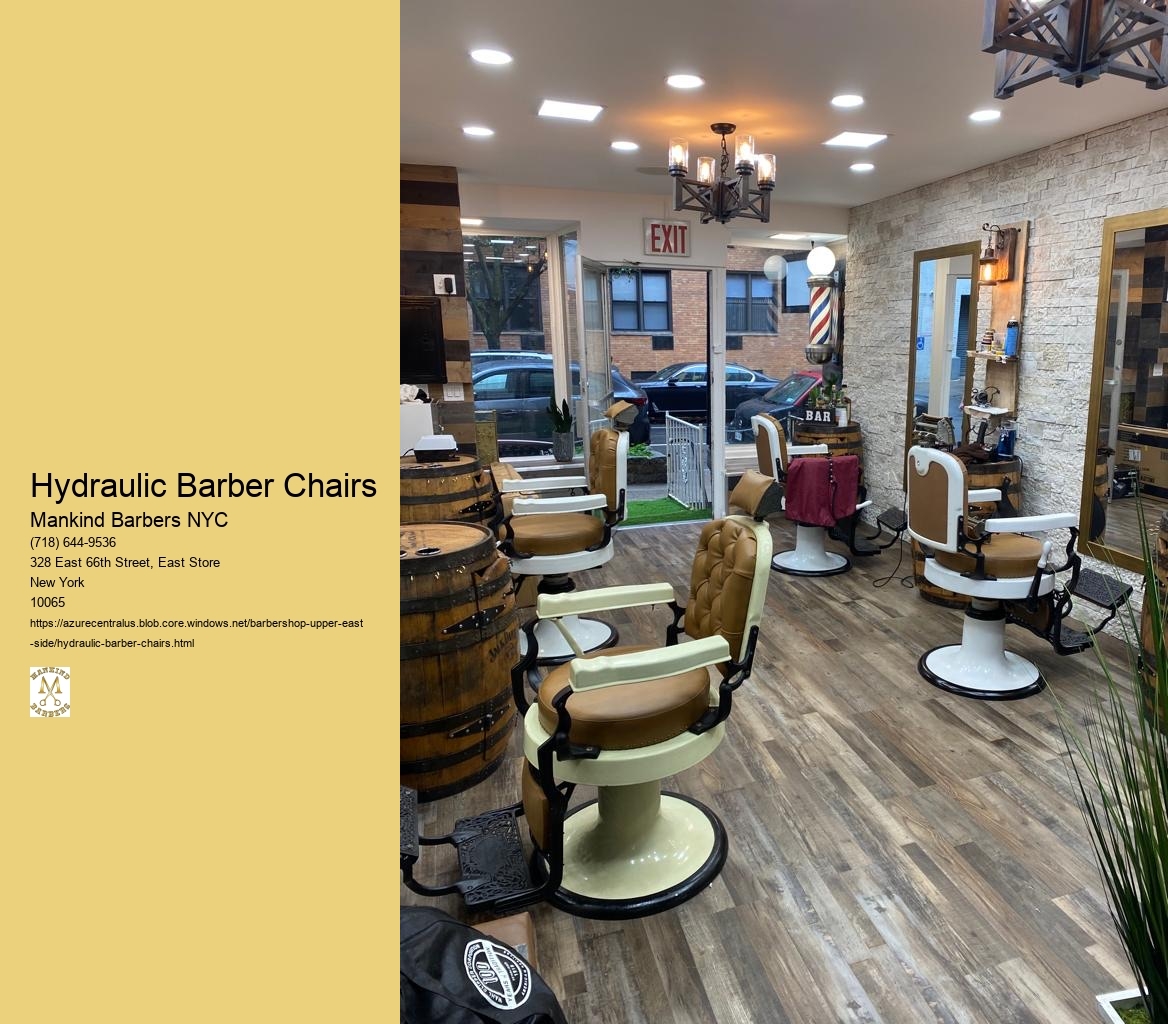

The hydraulic system in barber chairs plays a crucial role in their adjustable height and reclining capabilities. The system utilizes hydraulic fluid, a pump, and cylinders to control the chair's movement. Clipper Guards and Attachments When the pump is activated, the hydraulic fluid is pressurized, causing the cylinders to extend or retract, thus adjusting the chair's height or recline angle. This system allows for smooth and precise adjustments, providing convenience for both the barber and the client during haircuts or other grooming services.

To ensure the long-term functionality of the hydraulic components in barber chairs, specific maintenance requirements must be followed. Regular inspection of hydraulic hoses, seals, and fittings is essential to detect any signs of wear or leaks. Additionally, the hydraulic fluid should be checked and replaced as needed to maintain proper lubrication and performance. Proper maintenance helps prevent issues such as fluid leaks, loss of pressure, or uneven movement, ultimately extending the lifespan of the hydraulic system in barber chairs.

The hydraulic system in barber chairs can be customized to accommodate different weight capacities and user preferences. Barber Razor Blades By adjusting the size and strength of the hydraulic cylinders, as well as the hydraulic fluid pressure, the chair can be tailored to support various body weights and provide the desired level of reclining resistance. This customization ensures that the chair can comfortably and safely accommodate a diverse range of clients, enhancing their overall experience in the barber shop.

Safety features are integrated into the hydraulic system of barber chairs to prevent accidents or malfunctions. Overload valves are commonly included to prevent the chair from collapsing under excessive weight, while pressure relief valves protect the system from damage due to over-pressurization. Barber Anti-Fatigue Mats Additionally, some chairs may feature locking mechanisms to secure the chair in a desired position, ensuring stability during use. These safety features contribute to a secure and reliable experience for both the barber and the client.

The hydraulic system significantly impacts the overall comfort and ergonomics of the barber chair for both the client and the barber. The smooth and precise adjustments provided by the hydraulic system contribute to a comfortable and efficient grooming experience. The ability to easily change the chair's height and recline angle allows the barber to work at an optimal position, reducing strain and fatigue. Simultaneously, clients can enjoy personalized seating positions, enhancing their comfort during services.

Common troubleshooting steps for addressing issues with the hydraulic system in barber chairs include identifying and repairing leaks, checking and adjusting hydraulic fluid levels, and inspecting hydraulic hoses and fittings for damage. If the chair exhibits uneven movement, the hydraulic cylinders and pump should be examined for potential malfunctions. Regular maintenance and prompt troubleshooting help ensure that the hydraulic system operates smoothly and reliably, providing a positive experience for both barbers and their clients.

Barber First Aid Kits

To remove hair buildup from barber shears, begin by wiping the blades with a soft, dry cloth to remove any loose hair and debris. Next, use a small brush or toothbrush to gently scrub the blades, focusing on the areas where hair tends to accumulate. For stubborn buildup, a few drops of blade oil can be applied to help loosen and remove the hair. After cleaning, wipe the blades with a clean, dry cloth to ensure they are free of any remaining debris. Regular maintenance and cleaning of barber shears will help to maintain their performance and longevity.

When it comes to achieving a precise and well-blended layered haircut, professional barbers often opt for high-quality shears designed specifically for this purpose. The best barber shears for achieving a layered haircut are typically those with sharp, convex blades that allow for clean and precise cutting. Look for shears with ergonomic handles for comfortable and controlled handling, as well as adjustable tension screws to customize the cutting experience. Additionally, consider shears with a fine-toothed texturizing blade for seamlessly blending layers and creating soft, natural-looking transitions. It's also beneficial to choose shears made from high-quality stainless steel or titanium for durability and long-lasting sharpness. By selecting shears that incorporate these features, barbers can effectively achieve the desired layered haircut with precision and finesse.

Holographic-coated barber shears offer several benefits for professional hairstylists. The holographic coating provides a durable and corrosion-resistant surface, ensuring longevity and optimal performance. The coating also enhances the shears' aesthetic appeal, making them a stylish and eye-catching addition to any barber's toolkit. Additionally, the holographic coating can reduce friction, resulting in smoother and more precise cutting motions. This can contribute to a more comfortable and efficient cutting experience for both the stylist and the client. Overall, holographic-coated barber shears combine functionality, durability, and visual appeal, making them a valuable investment for any hairstyling professional.

Barber shears can be a versatile tool for creating intricate braided hairstyles, especially when working with fine or thick hair textures. The sharp, precise blades of barber shears allow for detailed sectioning and cutting, enabling the stylist to achieve clean, defined lines and intricate patterns in the braids. Additionally, the ergonomic design of barber shears provides comfort and control, facilitating the intricate weaving and manipulation of hair strands. When used skillfully, barber shears can contribute to the precision and artistry required for elaborate braided hairstyles, making them a valuable asset in the hairstyling toolkit.

Cobalt alloy barber shears offer several benefits that make them a popular choice among professional barbers. The high-quality cobalt alloy material provides exceptional durability, ensuring that the shears maintain their sharpness and cutting performance over time. This results in precise and clean cuts, reducing the need for frequent sharpening and maintenance. Additionally, the cobalt alloy's resistance to corrosion and wear further enhances the longevity of the shears, making them a reliable tool for long-term use. The superior strength of cobalt alloy also allows for the creation of thinner and lighter blades, promoting effortless and precise cutting motions. Furthermore, the ergonomic design of cobalt alloy shears contributes to comfortable handling, reducing strain and fatigue during prolonged use. Overall, the combination of durability, sharpness, corrosion resistance, and ergonomic features makes cobalt alloy barber shears a valuable investment for professional barbers seeking high-performance tools.

Japanese-style barber shears offer a range of benefits that cater to the specific needs of professional hairstylists. These shears are renowned for their precision, sharpness, and ergonomic design, allowing for effortless and accurate hair cutting. The high-quality steel used in Japanese shears ensures durability and longevity, making them a worthwhile investment for barbers and hairstylists. Additionally, the convex edge blades of Japanese shears provide a smooth and clean cut, reducing hair damage and split ends. The lightweight and well-balanced construction of these shears also minimizes hand and wrist fatigue during prolonged use, promoting comfort and efficiency. Overall, the use of Japanese-style barber shears can enhance the cutting experience, resulting in impeccable and professional haircuts.

When selecting the appropriate blade material for barber shears, it is essential to consider factors such as durability, sharpness, and corrosion resistance. High-carbon stainless steel, cobalt steel, and Damascus steel are popular choices due to their exceptional hardness, edge retention, and resistance to corrosion. Additionally, titanium-coated blades offer increased durability and reduced friction, while ceramic blades provide lightweight and corrosion-resistant properties. It is important to assess the specific cutting needs and preferences of the barber, as well as the maintenance requirements associated with each blade material, to make an informed decision. By considering these factors, one can select the most suitable blade material for their barber shears, ensuring optimal performance and longevity.