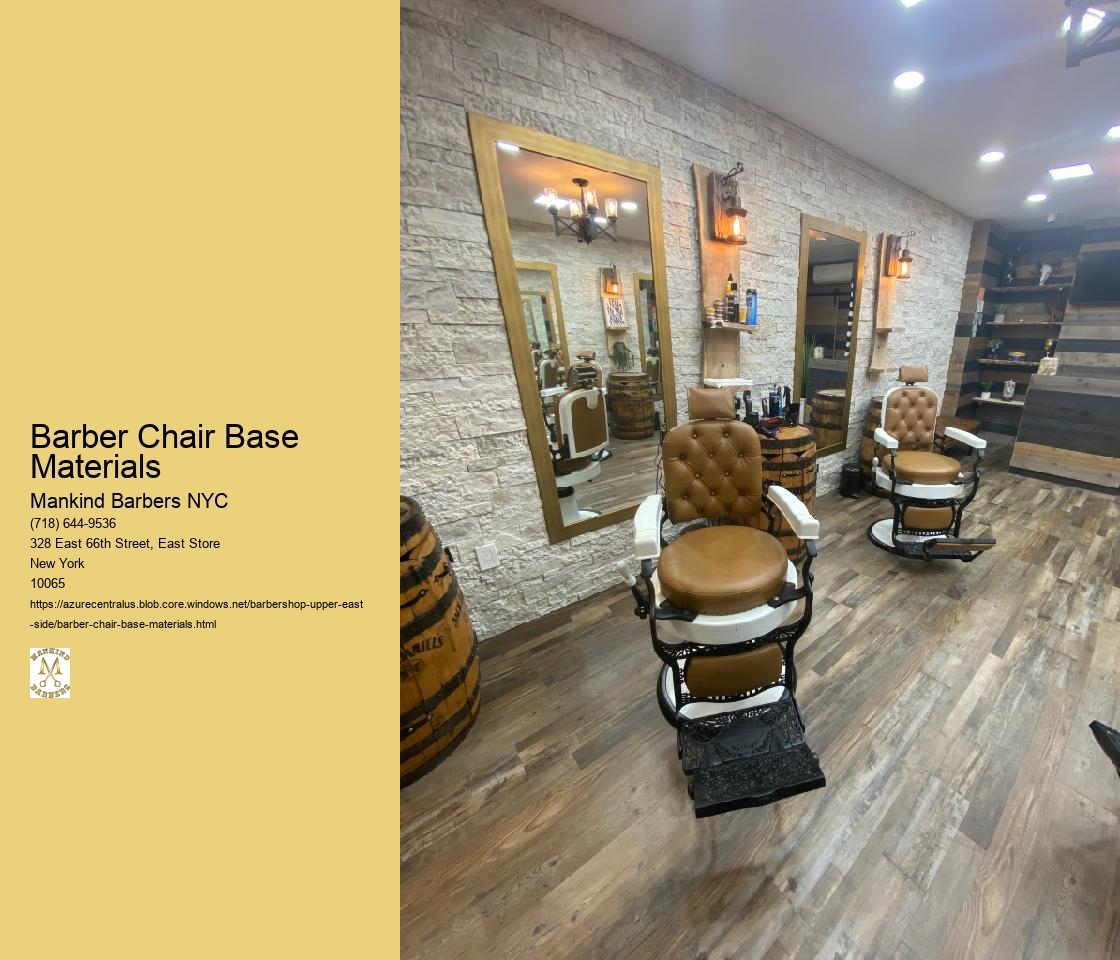

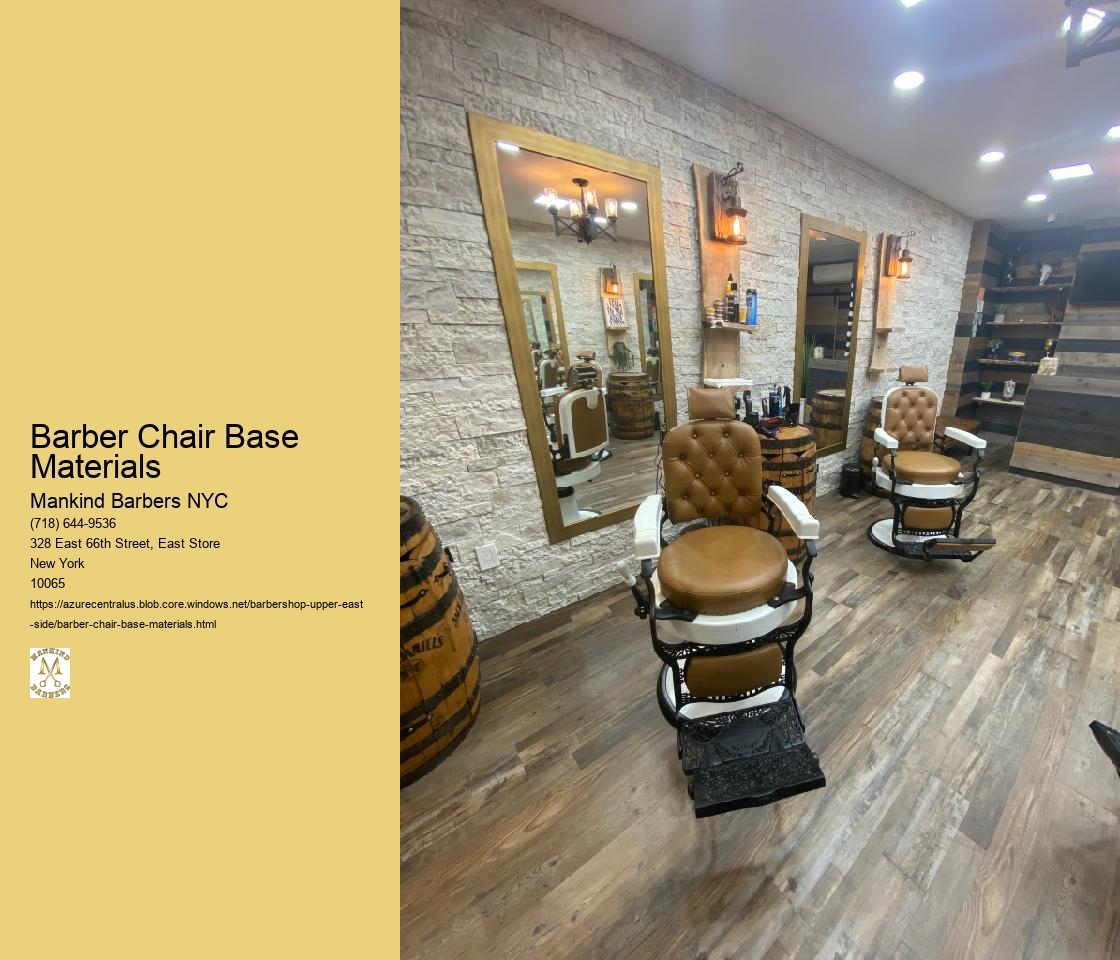

Barber chairs commonly use materials such as heavy-duty steel, aluminum, and cast iron for their bases. Heavy-duty steel is often preferred for its strength and durability, providing a stable foundation for the chair. Aluminum bases are lightweight and corrosion-resistant, making them a popular choice for barber chairs. Shaving Bowls and Brushes Cast iron is known for its exceptional strength and stability, making it a reliable option for supporting the weight of the chair and the person sitting in it.

Stainless steel barber chair bases are highly durable and resistant to corrosion, making them suitable for long-term use. Barber Shop Decorations They require minimal maintenance and are easy to clean, making them a practical choice for barber chairs. On the other hand, aluminum bases are also durable and lightweight, but they may require more frequent maintenance to prevent corrosion and ensure longevity.

Using cast iron as a material for barber chair bases offers specific advantages, such as exceptional stability and weight-bearing capacity. Hair Setting Lotions Cast iron is known for its high strength and resistance to wear and tear, making it a reliable choice for supporting the weight of the chair and providing a stable foundation for the barber's work.

The weight-bearing capacities of different types of barber chair bases vary depending on the material and construction. Chrome-plated steel bases are known for their strength and durability, providing a high weight-bearing capacity. Similarly, powder-coated steel bases offer robust support and can withstand heavy loads, making them suitable for various body types and sizes.

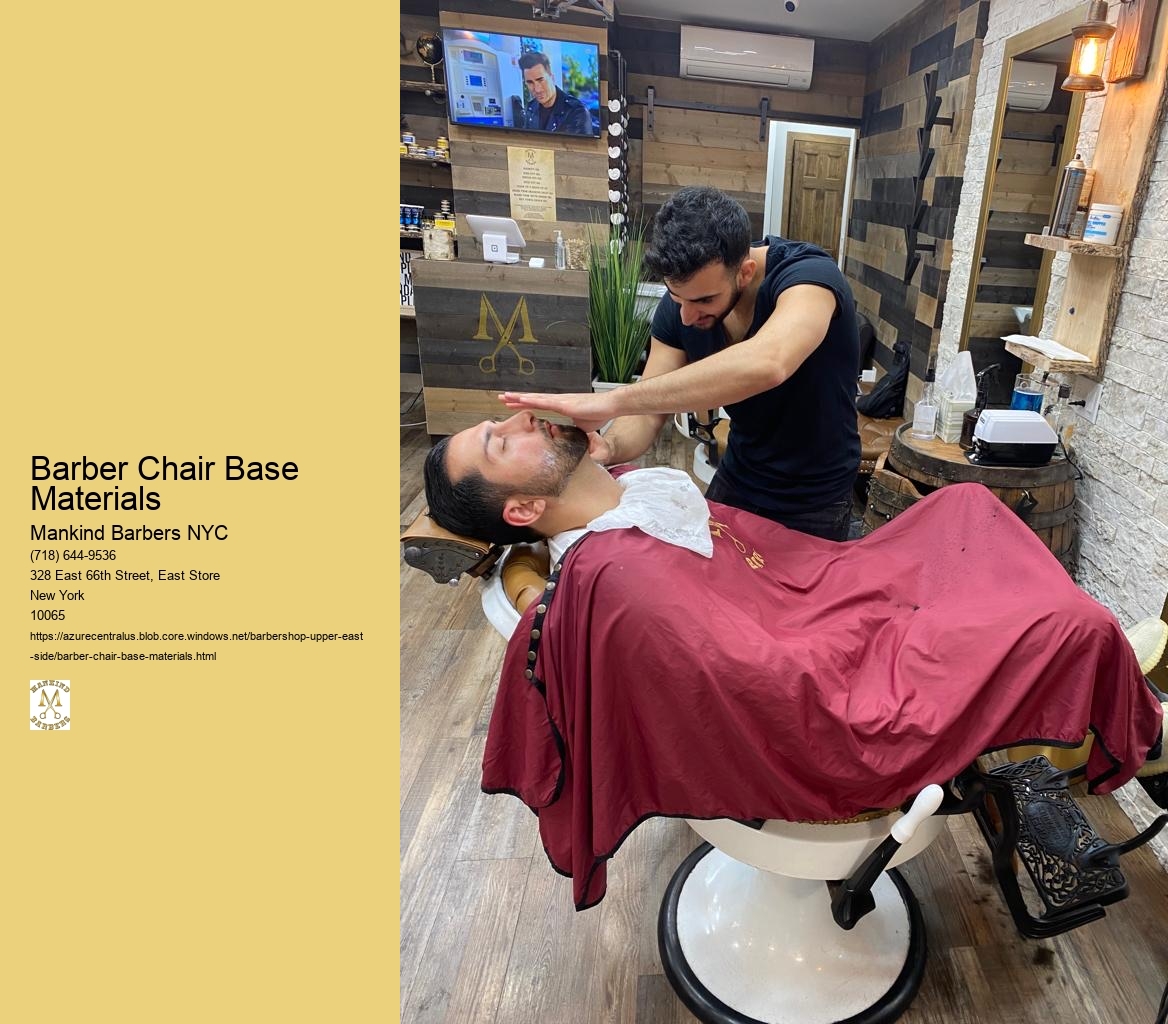

Hydraulic pump bases and electric motor bases both offer stability and sturdiness, but they differ in their mechanisms. Hydraulic pump bases use hydraulic fluid to adjust the chair's height, providing smooth and controlled movement. Electric motor bases, on the other hand, use an electric motor for height adjustment, offering precise control and convenience. Both types provide reliable stability, but the choice depends on specific preferences and requirements.

When choosing the material for a barber chair base, environmental considerations such as recyclability and sustainability are important. Opting for materials that are recyclable and sustainable can contribute to reducing environmental impact. Barber First Aid Kits For example, choosing aluminum or steel bases made from recycled materials can support eco-friendly practices in the salon industry.

Maintenance requirements for different types of barber chair bases vary based on the material. Chrome bases may require regular cleaning and polishing to maintain their luster and prevent corrosion. Powder-coated steel bases are relatively low-maintenance, requiring occasional cleaning to remove dirt and debris. Brushed aluminum bases may need gentle cleaning to preserve their finish and prevent scratches. Hair Styling Products Understanding the specific maintenance needs of each material is essential for ensuring the longevity and appearance of the barber chair bases.

Japanese-style barber shears offer a range of benefits that cater to the specific needs of professional hairstylists. These shears are renowned for their precision, sharpness, and ergonomic design, allowing for effortless and accurate hair cutting. The high-quality steel used in Japanese shears ensures durability and longevity, making them a worthwhile investment for barbers and hairstylists. Additionally, the convex edge blades of Japanese shears provide a smooth and clean cut, reducing hair damage and split ends. The lightweight and well-balanced construction of these shears also minimizes hand and wrist fatigue during prolonged use, promoting comfort and efficiency. Overall, the use of Japanese-style barber shears can enhance the cutting experience, resulting in impeccable and professional haircuts.

When selecting the appropriate blade material for barber shears, it is essential to consider factors such as durability, sharpness, and corrosion resistance. High-carbon stainless steel, cobalt steel, and Damascus steel are popular choices due to their exceptional hardness, edge retention, and resistance to corrosion. Additionally, titanium-coated blades offer increased durability and reduced friction, while ceramic blades provide lightweight and corrosion-resistant properties. It is important to assess the specific cutting needs and preferences of the barber, as well as the maintenance requirements associated with each blade material, to make an informed decision. By considering these factors, one can select the most suitable blade material for their barber shears, ensuring optimal performance and longevity.

Barber shears can be used for thinning out natural curls, as they are designed to provide precise and controlled cutting. When using barber shears for thinning curly hair, it's important to consider the specific texture and density of the curls to achieve the desired result. Thinning shears, also known as texturizing shears, can help to reduce bulk and create a more balanced and manageable look for natural curls. It's essential to use the shears with caution and skill to avoid over-thinning or causing damage to the hair. Additionally, consulting with a professional hairstylist who is experienced in working with curly hair can provide valuable insights and recommendations for achieving the best results with barber shears.

Barber shears can be used for cutting clip-in hair extensions, as they are designed to provide precise and clean cuts. The sharp blades of barber shears allow for accurate trimming of the extensions, ensuring a seamless blend with the natural hair. When using barber shears for this purpose, it's important to handle the extensions with care to avoid any damage or uneven cuts. Additionally, it's advisable to use high-quality shears specifically designed for hair cutting to achieve the best results. Proper maintenance and regular sharpening of the shears will also contribute to maintaining their cutting efficiency for both natural hair and extensions.

Ceramic barber shears do offer several advantages over steel shears. The use of ceramic material provides lightweight and ergonomic design, reducing hand fatigue during prolonged use. Additionally, ceramic shears are known for their resistance to corrosion and rust, ensuring longevity and durability. The smooth and sharp cutting edges of ceramic shears also contribute to precise and clean cuts, making them ideal for intricate and detailed hair cutting techniques. Furthermore, ceramic shears are less prone to heat damage, making them suitable for use with heat-based styling tools. Overall, the unique properties of ceramic shears make them a favorable choice for professional barbers seeking high-performance and reliable cutting tools.

When it comes to creating asymmetrical hairstyles, professional barbers often rely on specialized shears designed for precision cutting. The best barber shears for this purpose are those with offset handles, allowing for a comfortable and ergonomic grip that enables precise control over the cutting angle. Look for shears with convex edges, as they provide a smooth and clean cut, essential for achieving the sharp lines and angles characteristic of asymmetrical styles. Additionally, consider shears with a fine-toothed blade for texturizing and blending, as well as a durable and lightweight design to minimize hand fatigue during intricate cutting techniques. Opting for high-quality Japanese steel shears can also ensure long-lasting sharpness and performance, crucial for achieving the desired asymmetrical look with finesse.