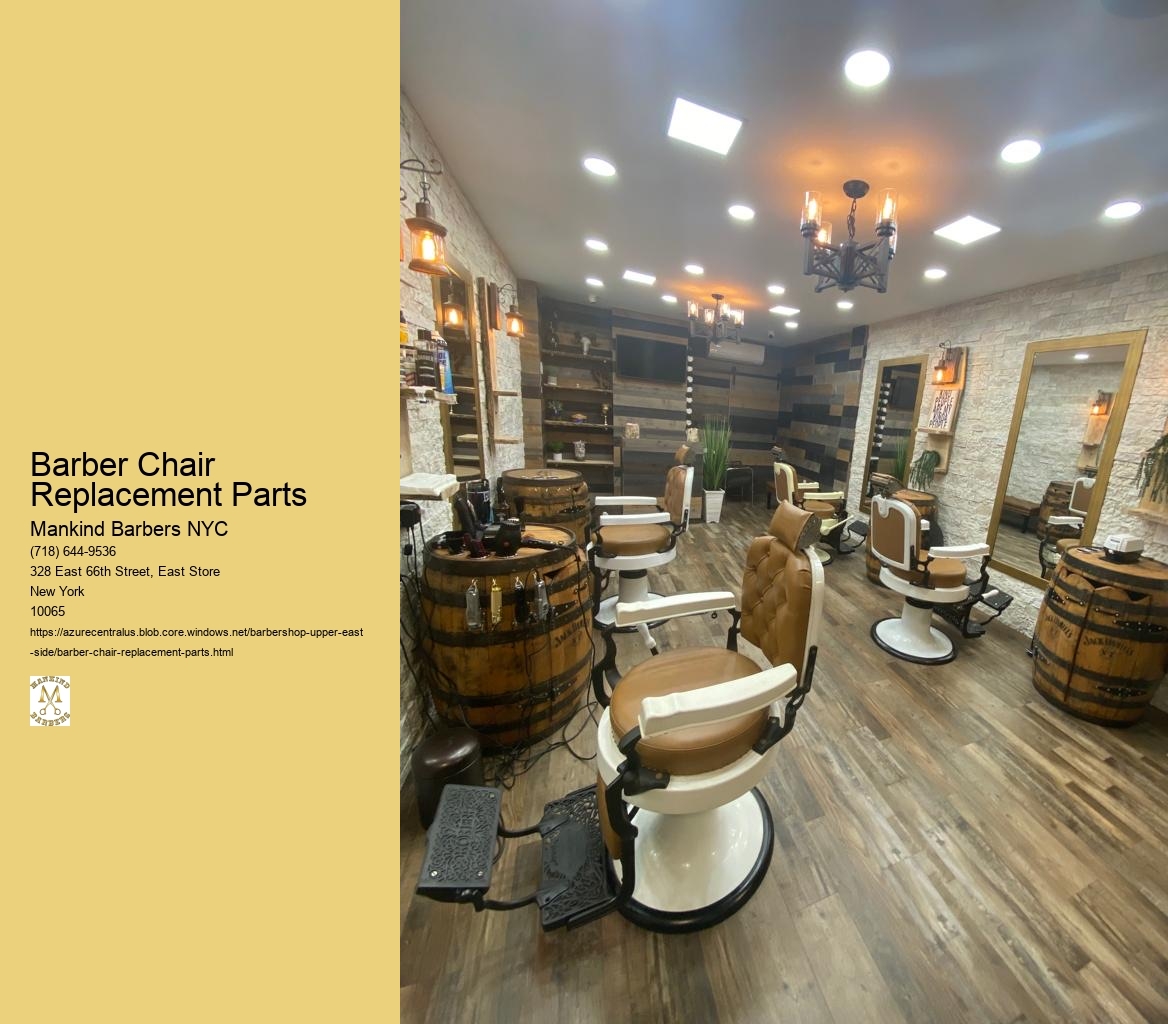

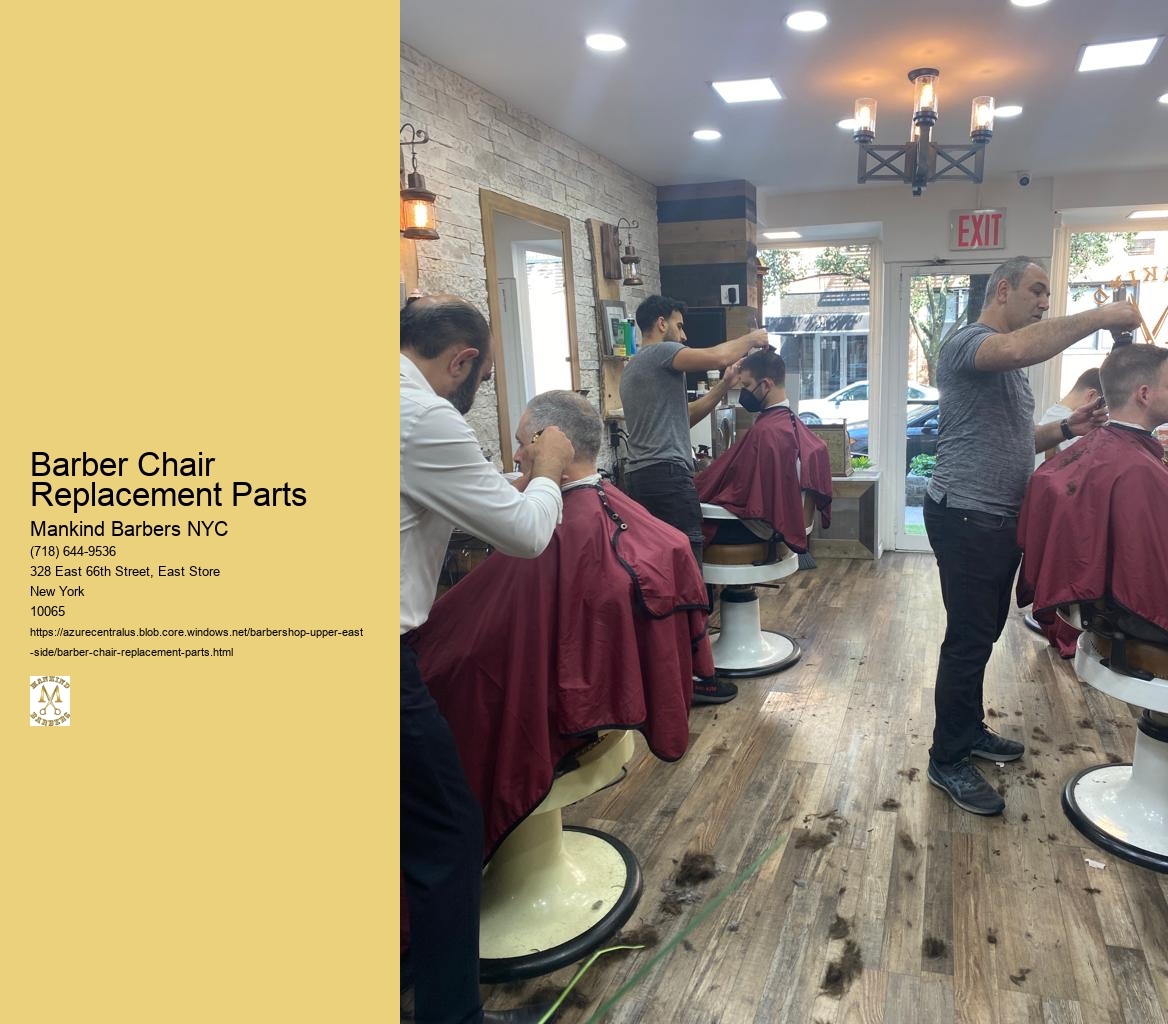

The most common replacement parts for hydraulic barber chairs include hydraulic pumps, footrests, upholstery, and reclining mechanisms. These parts are essential for ensuring the functionality and comfort of the chair. Hydraulic pumps are crucial for adjusting the height of the chair, while footrests provide support for clients during their grooming experience. Upholstery replacement is often necessary to maintain the aesthetic appeal and comfort of the chair, and reclining mechanisms are vital for allowing clients to recline during services.

Barber DisinfectantsDetermining the correct size and model of footrest for a barber chair involves measuring the dimensions of the existing footrest and identifying the specific model of the chair. It's important to ensure that the replacement footrest matches the dimensions and design of the original part to guarantee a proper fit and functionality. Shaving Brushes Additionally, consulting the chair's manual or contacting the manufacturer can provide valuable guidance in selecting the appropriate footrest for the specific model of the barber chair.

Vintage or antique barber chairs may require specific replacement parts due to their unique design and construction. It's essential to source replacement parts from specialized suppliers or manufacturers that cater to vintage and antique barber chairs. These suppliers often offer authentic and compatible parts that are tailored to the specific requirements of vintage chairs, ensuring the preservation of their historical and aesthetic value.

Best practices for maintaining and lubricating the hydraulic pump in a barber chair involve regular inspection and lubrication of the pump components. It's important to follow the manufacturer's guidelines for lubrication intervals and use high-quality lubricants suitable for hydraulic systems. Additionally, keeping the pump free from debris and ensuring proper hydraulic fluid levels are essential for maintaining the pump's performance and longevity.

Barber Educational BooksUpholstery and padding on a barber chair can be replaced to refresh the chair's appearance and comfort. Replacement materials such as vinyl, leather, or fabric upholstery, as well as high-density foam padding, can be sourced from specialized suppliers or upholstery shops. It's crucial to select materials that are durable, easy to clean, and compatible with the chair's design to ensure a professional and long-lasting result.

Specific safety standards and regulations for replacement parts in barber chairs are governed by industry organizations and regulatory bodies. Hair Rollers It's important to source replacement parts that comply with relevant safety standards and regulations to ensure the chair's safety and performance. Working with reputable suppliers and manufacturers who adhere to industry standards can provide assurance that the replacement parts meet the necessary safety requirements.

Troubleshooting and fixing issues with reclining mechanisms in barber chairs may involve inspecting the mechanical components, such as levers, springs, and locking mechanisms, for any signs of wear or damage. It's important to follow the chair's manual or seek guidance from the manufacturer for specific troubleshooting steps. Additionally, ensuring that the chair is properly assembled and adjusted can help address common issues with reclining mechanisms, providing a comfortable and functional experience for clients.

Barber Stools

To sharpen cobalt alloy barber shears, it is important to use a high-quality sharpening stone or a professional sharpening service that specializes in sharpening barber shears. The process involves carefully honing the blades to ensure a precise and sharp edge. It is crucial to use the appropriate angle and pressure to maintain the integrity of the cobalt alloy while achieving optimal sharpness. Additionally, using a lubricant during the sharpening process can help prevent overheating and maintain the shears' performance. Regular maintenance and sharpening of cobalt alloy barber shears are essential to ensure they continue to deliver precise and effective cutting performance.

Barber shears can exhibit several signs when they are in need of sharpening. One indication is the shears struggling to cut hair smoothly, resulting in a jagged or uneven finish. Another sign is an increase in the amount of pressure required to cut hair, as dull shears may start to pull or tug at the hair rather than cleanly slicing through it. Additionally, if the shears are leaving behind frayed or split ends, this could also indicate that they are in need of sharpening. It's also worth noting that if the shears are making a louder or more abrasive sound during cutting, this could be a sign of dullness. Regular maintenance and periodic sharpening can help ensure that the shears remain in optimal condition for precise and efficient hair cutting.

Barber shears should ideally be replaced every 6 months to a year, depending on the frequency of use and the quality of the shears. Regular maintenance, such as cleaning, oiling, and sharpening, can extend the lifespan of the shears. However, over time, the blades can become dull and worn, affecting the precision and quality of the haircut. It's important to monitor the condition of the shears and replace them when signs of wear and tear become apparent to ensure optimal performance and client satisfaction. Regularly investing in high-quality shears can also contribute to longevity and performance.

When it comes to precision cutting, barbers often seek shears that offer exceptional sharpness, control, and durability. The best barber shears for precision cutting are typically crafted from high-quality Japanese stainless steel, known for its superior hardness and edge retention. Look for shears with convex edges, which provide a smooth and precise cutting action. Additionally, ergonomic designs and adjustable tension systems can enhance comfort and control during intricate cutting techniques. Some popular choices among barbers include shears with offset handles, removable finger rests, and fine-toothed blades for detailed work. Ultimately, the best barber shears for precision cutting are those that offer a perfect balance of sharpness, agility, and ergonomic features to meet the demands of intricate hair styling.

Regular hair scissors and barber shears differ in several key aspects. Barber shears are specifically designed for professional use in a barber or salon setting, featuring longer blades and a more ergonomic design to facilitate precise and efficient cutting. They are often made of high-quality stainless steel or other durable materials to withstand frequent use. In contrast, regular hair scissors are more commonly used for at-home hair cutting and may have shorter blades and a simpler design. While both tools are used for cutting hair, barber shears are typically preferred by professionals for their superior performance and durability.

Convex and semi-convex barber shears differ in the shape of their blades and the cutting technique they offer. Convex shears have a very sharp edge that is curved, allowing for a smooth and precise cut. They are designed to create clean, effortless cuts with minimal force, making them ideal for detailed and intricate hair cutting. On the other hand, semi-convex shears have a slightly beveled edge, providing a balance between sharpness and durability. They are versatile and suitable for a wide range of cutting styles, offering a combination of precision and strength. Both types of shears have their own advantages and are chosen based on the specific cutting needs and preferences of the barber or stylist.