To assess the durability of barber aprons, specific tests are conducted, including abrasion resistance testing, tear strength testing, and colorfastness testing. Abrasion resistance testing evaluates the fabric's ability to withstand friction and wear, while tear strength testing measures the force required to tear the fabric. Barber Sterilizers Colorfastness testing assesses the fabric's ability to retain its color when exposed to various conditions, such as washing and light exposure.

The material composition of barber aprons significantly impacts their durability. Aprons made from durable materials such as heavy-duty canvas, polyester blends, or denim are more resistant to wear and tear. These materials offer high tensile strength, abrasion resistance, and colorfastness, contributing to the overall longevity of the apron. Additionally, the use of reinforced stitching and durable hardware enhances the durability of the apron.

Shaving Cream and GelIn the barber industry, there are no specific industry standards or regulations that barber aprons must meet in terms of durability. However, many manufacturers adhere to general textile industry standards and guidelines for durability testing, ensuring that their aprons meet high-quality standards and can withstand the rigors of daily use in a barber shop environment.

Common factors that contribute to wear and tear on barber aprons include exposure to hair clippings, chemicals, and water, as well as frequent washing and movement during use. These factors are addressed in durability testing by subjecting the aprons to simulated real-world conditions, such as exposure to water and chemicals, repeated washing cycles, and mechanical stress to assess their performance and longevity.

Hair CurlersThe design and construction of barber aprons play a crucial role in their longevity and durability. Aprons with reinforced seams, adjustable neck and waist straps, and strategically placed pockets are designed to withstand the demands of a barber's daily activities. Additionally, the use of double-stitched hems, bar-tacked stress points, and high-quality hardware enhances the overall durability of the apron.

Barber aprons are tested for durability under specific environmental conditions and scenarios, including exposure to water, hair clippings, and chemical products commonly used in a barber shop setting. Additionally, durability testing may involve subjecting the aprons to temperature variations, UV exposure, and repeated laundering to simulate real-world usage conditions.

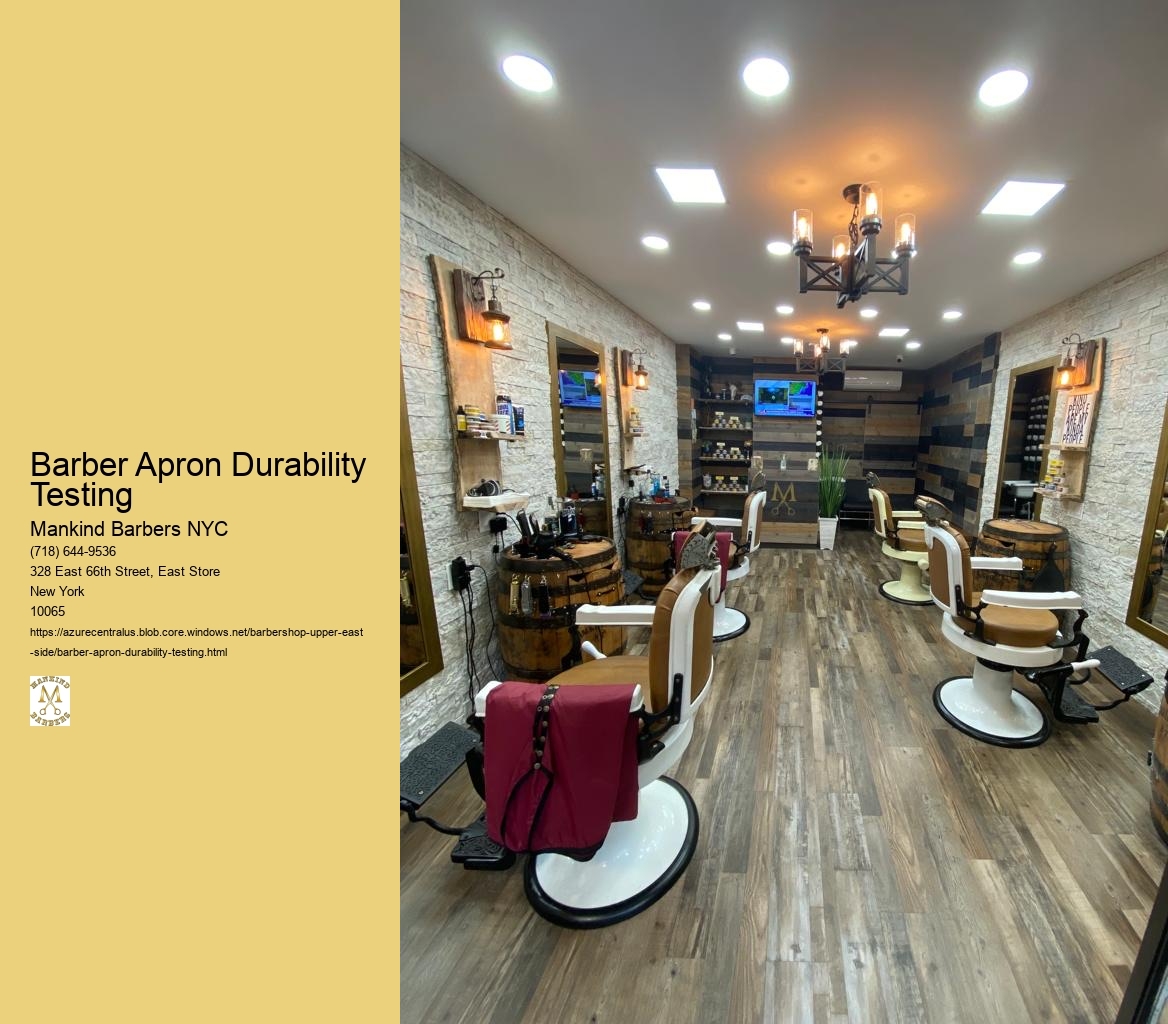

Barber Shop Waiting Area FurnitureTo ensure that the durability testing of barber aprons accurately reflects real-world usage and conditions, manufacturers often conduct field trials and gather feedback from barbers who use the aprons in their daily work. This real-world feedback is valuable in assessing the apron's performance, identifying any potential durability issues, and making necessary improvements to enhance the overall quality and longevity of the product. Trimmers Additionally, ongoing quality control measures and continuous testing help manufacturers maintain high standards of durability for their barber aprons.

When selecting the appropriate blade material for barber shears, it is essential to consider factors such as durability, sharpness, and corrosion resistance. High-carbon stainless steel, cobalt steel, and Damascus steel are popular choices due to their exceptional hardness, edge retention, and resistance to corrosion. Additionally, titanium-coated blades offer increased durability and reduced friction, while ceramic blades provide lightweight and corrosion-resistant properties. It is important to assess the specific cutting needs and preferences of the barber, as well as the maintenance requirements associated with each blade material, to make an informed decision. By considering these factors, one can select the most suitable blade material for their barber shears, ensuring optimal performance and longevity.

Barber shears can be used for thinning out natural curls, as they are designed to provide precise and controlled cutting. When using barber shears for thinning curly hair, it's important to consider the specific texture and density of the curls to achieve the desired result. Thinning shears, also known as texturizing shears, can help to reduce bulk and create a more balanced and manageable look for natural curls. It's essential to use the shears with caution and skill to avoid over-thinning or causing damage to the hair. Additionally, consulting with a professional hairstylist who is experienced in working with curly hair can provide valuable insights and recommendations for achieving the best results with barber shears.

Barber shears can be used for cutting clip-in hair extensions, as they are designed to provide precise and clean cuts. The sharp blades of barber shears allow for accurate trimming of the extensions, ensuring a seamless blend with the natural hair. When using barber shears for this purpose, it's important to handle the extensions with care to avoid any damage or uneven cuts. Additionally, it's advisable to use high-quality shears specifically designed for hair cutting to achieve the best results. Proper maintenance and regular sharpening of the shears will also contribute to maintaining their cutting efficiency for both natural hair and extensions.

Ceramic barber shears do offer several advantages over steel shears. The use of ceramic material provides lightweight and ergonomic design, reducing hand fatigue during prolonged use. Additionally, ceramic shears are known for their resistance to corrosion and rust, ensuring longevity and durability. The smooth and sharp cutting edges of ceramic shears also contribute to precise and clean cuts, making them ideal for intricate and detailed hair cutting techniques. Furthermore, ceramic shears are less prone to heat damage, making them suitable for use with heat-based styling tools. Overall, the unique properties of ceramic shears make them a favorable choice for professional barbers seeking high-performance and reliable cutting tools.

When it comes to creating asymmetrical hairstyles, professional barbers often rely on specialized shears designed for precision cutting. The best barber shears for this purpose are those with offset handles, allowing for a comfortable and ergonomic grip that enables precise control over the cutting angle. Look for shears with convex edges, as they provide a smooth and clean cut, essential for achieving the sharp lines and angles characteristic of asymmetrical styles. Additionally, consider shears with a fine-toothed blade for texturizing and blending, as well as a durable and lightweight design to minimize hand fatigue during intricate cutting techniques. Opting for high-quality Japanese steel shears can also ensure long-lasting sharpness and performance, crucial for achieving the desired asymmetrical look with finesse.

When it comes to creating modern mullet hairstyles, barbers often seek shears that offer precision and versatility. The best barber shears for this purpose are those with sharp, fine-toothed blades that allow for detailed texturizing and layering. Look for shears with ergonomic handles for comfortable and controlled handling during intricate cutting techniques. Additionally, consider shears with adjustable tension screws to customize the cutting experience. Opt for high-quality stainless steel shears that provide durability and long-lasting sharpness. Some barbers also prefer shears with a convex edge for smooth and effortless cutting. These features can help barbers achieve the precise and edgy look required for modern mullet hairstyles.

Offset handle barber shears offer several benefits for professional barbers and hairstylists. The ergonomic design of the offset handle provides a more natural and comfortable hand position, reducing strain and fatigue during long hours of use. This can lead to improved precision and control, resulting in cleaner and more accurate cuts. The offset handle also allows for better visibility and access to the hair, making it easier to create intricate and detailed styles. Additionally, the offset design can help reduce the risk of repetitive strain injuries, making it a popular choice among professionals who prioritize comfort and long-term health. Overall, the use of offset handle barber shears can enhance the cutting experience and contribute to better results for both the stylist and the client.