Barber aprons typically use reinforced stitching, such as lockstitch or chain stitch, to ensure durability and longevity. These stitching techniques involve interlocking the threads to create a strong, secure bond that can withstand the rigors of frequent use and washing. By utilizing these specialized stitching methods, barber aprons can maintain their structural integrity and resist unraveling or fraying, even in high-traffic barbershops.

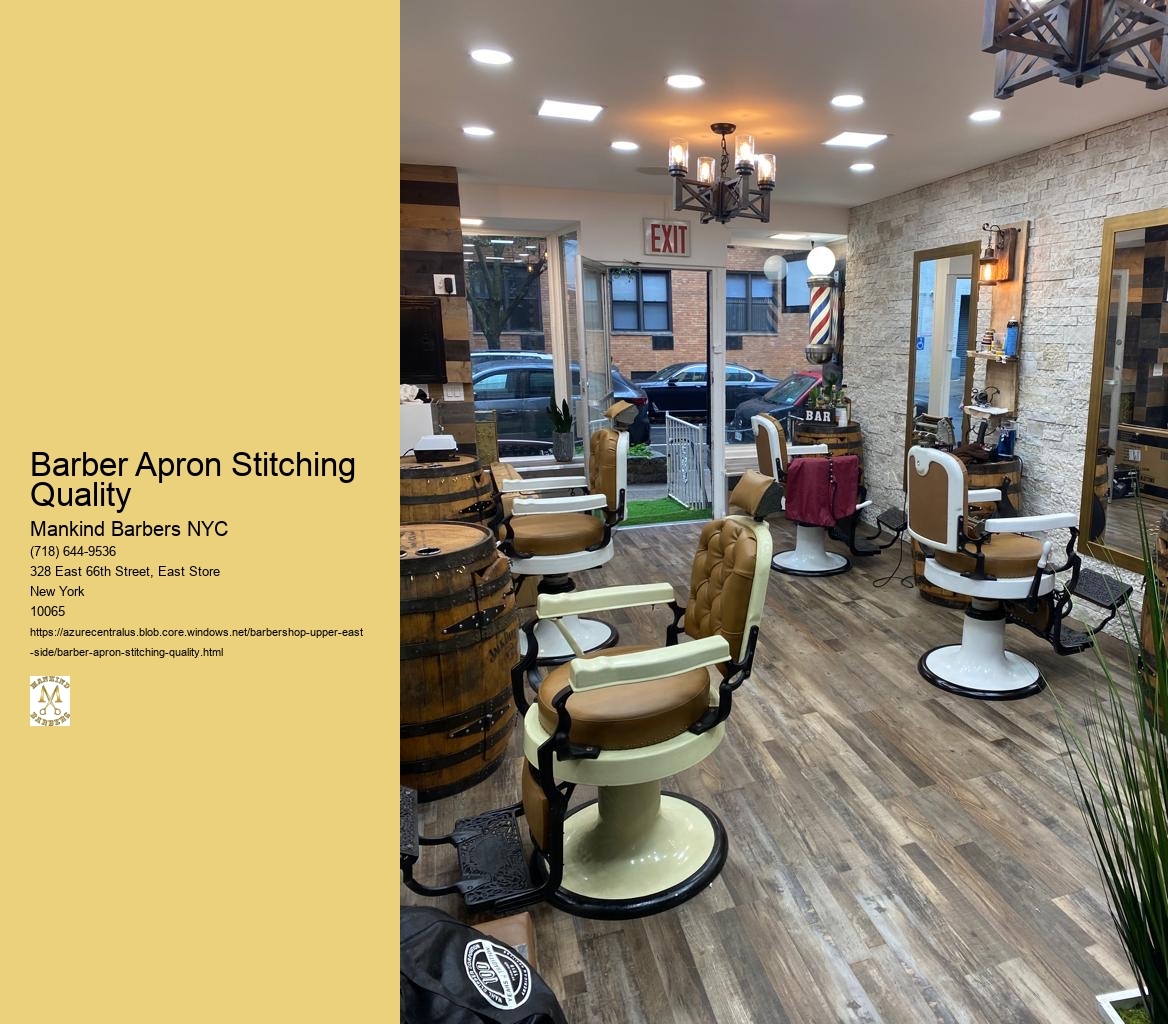

Barber ChairsTo withstand frequent use and washing, barber aprons benefit from specific stitching techniques that enhance their resilience. For instance, using bar-tack stitching at stress points, such as pockets and waist ties, can reinforce these areas and prevent seam failure. Additionally, employing double stitching along the edges and seams can provide extra strength and prevent fraying, ensuring that the apron remains intact through repeated use and laundering.

High-quality stitching in a barber apron can be identified by examining the density and consistency of the stitches. Look for tightly spaced stitches with uniform tension, as this indicates a robust construction that can withstand the demands of a busy barbershop. Additionally, inspect the seam allowances and edges for clean, finished stitching, which further contributes to the apron's durability and longevity.

Common stitching issues to look out for in barber aprons include loose or uneven stitches, skipped stitches, and fraying threads. Barber Shop Waiting Area Furniture These issues can compromise the structural integrity of the apron and lead to premature wear and tear. To prevent these problems, regular maintenance and inspection of the aprons are essential. Loose threads should be trimmed, and any loose or uneven stitches should be reinforced to prevent further unraveling.

When stitching barber aprons, it is recommended to use high-quality thread materials such as polyester or nylon. These synthetic threads offer superior strength and resilience, ensuring that the stitching can withstand the stresses of daily use and frequent washing. Barber Tool Belts Additionally, using colorfast threads can prevent fading and maintain the apron's aesthetic appeal over time.

Superior stitching quality in barber aprons can be assessed by examining the seam construction, stitch density, and overall neatness of the stitching. Look for reinforced seams, consistent stitching patterns, and secure thread ends. Additionally, consider the type of stitching used, such as lockstitch or chain stitch, as these techniques contribute to the apron's durability. Barber Shop Lighting Fixtures By evaluating these indicators, one can make an informed decision when selecting a high-quality barber apron.

While there may not be specific standards or certifications for stitching quality in barber aprons, customers should look for reputable brands and manufacturers known for their attention to detail and craftsmanship. Barber Neck Collars Additionally, customer reviews and testimonials can provide valuable insights into the stitching quality and overall durability of barber aprons. By researching the reputation of the brand and assessing customer feedback, shoppers can make informed choices when selecting a barber apron that meets their quality standards.

Maintaining the alignment of barber shears is crucial for ensuring precise and effective hair cutting. To achieve this, it is important to regularly check and adjust the tension screw to keep the blades properly aligned. Additionally, using a high-quality shear oil to lubricate the pivot point and blades can help maintain smooth movement and prevent misalignment. Proper storage in a protective case or pouch can also prevent damage and ensure the shears remain in optimal condition. Regular professional sharpening and servicing by a qualified technician can further help maintain the alignment and overall performance of the barber shears.

When looking for the best barber shears to achieve a disconnected undercut, it's essential to consider shears that offer precision and control. Look for shears with a sharp, convex edge blade for clean and precise cutting. Additionally, consider shears with ergonomic handles for comfort and ease of use during intricate cutting techniques. Opt for shears with a fine-tuned tension system to ensure smooth and effortless cutting motions. It's also beneficial to choose shears with a lightweight design to minimize hand fatigue during extended use. Considering these factors, shears with a high-quality steel construction and a versatile length, such as 6 to 7 inches, can provide the necessary tools for achieving a seamless disconnected undercut.

When it comes to high-quality barber shears, several top brands stand out in the market. Some of the best brands known for their precision, durability, and ergonomic design include Kamisori, Hanzo, Mizutani, and Jaguar. These brands are renowned for their sharp blades, comfortable handles, and overall craftsmanship, making them popular choices among professional barbers and hairstylists. Additionally, brands like Kasho, Yasaka, and Joewell also offer a wide range of barber shears that cater to different cutting techniques and preferences. With their focus on innovation and performance, these brands continue to set the standard for excellence in the barber shear industry.

Titanium-coated barber shears offer several benefits that make them a popular choice among professional barbers and hairstylists. The titanium coating provides increased durability and resistance to corrosion, ensuring that the shears maintain their sharpness and performance over time. This coating also reduces friction, allowing for smoother and more precise cutting, which is essential for achieving clean and accurate haircuts. Additionally, the titanium coating adds a layer of protection against chemical and moisture damage, prolonging the lifespan of the shears. Overall, the use of titanium-coated barber shears can enhance the efficiency and quality of hair cutting, making them a valuable tool for professionals in the industry.

Yes, there are barber shears available with removable finger inserts for customization. These shears are designed to provide a comfortable and personalized grip for the user. The removable finger inserts allow for easy customization to fit the individual's hand size and finger placement preferences. This feature enhances the ergonomic design of the shears, providing a more comfortable and precise cutting experience. Additionally, the removable finger inserts also allow for easy cleaning and maintenance of the shears, ensuring hygiene and longevity of the tool. These customizable barber shears offer a versatile and tailored cutting experience for professionals and enthusiasts alike.

Black ceramic barber shears offer several benefits for professional barbers and hairstylists. The use of ceramic in the construction of the shears provides exceptional durability and resistance to corrosion, ensuring a longer lifespan for the tool. The lightweight nature of the material also reduces hand fatigue during extended use, promoting comfort and precision. Additionally, the sharpness and edge retention of black ceramic blades allow for effortless and precise cutting, contributing to a smoother and more efficient haircutting experience. The sleek black color also adds a stylish and modern aesthetic to the shears, making them a popular choice among professionals in the industry. Overall, the use of black ceramic barber shears can enhance the cutting performance, durability, and visual appeal for barbers and hairstylists.

Barber shears are not recommended for cutting tape-in hair extensions as they are designed for cutting hair and may not provide the precision required for working with extensions. It is advisable to use specialized hair extension shears or sharp, high-quality scissors specifically designed for cutting tape-in hair extensions. These tools are designed to ensure clean, precise cuts without damaging the extensions or causing uneven edges. Using the appropriate tools will help maintain the integrity of the extensions and ensure a professional, seamless blend with the natural hair.