Pitting in helical gear teeth can be caused by a variety of factors, including surface fatigue due to repeated contact stress, inadequate lubrication leading to increased friction and wear, and contamination from debris or foreign particles. These issues can create small pits or craters on the gear teeth, compromising their integrity and potentially leading to further damage if not addressed promptly.

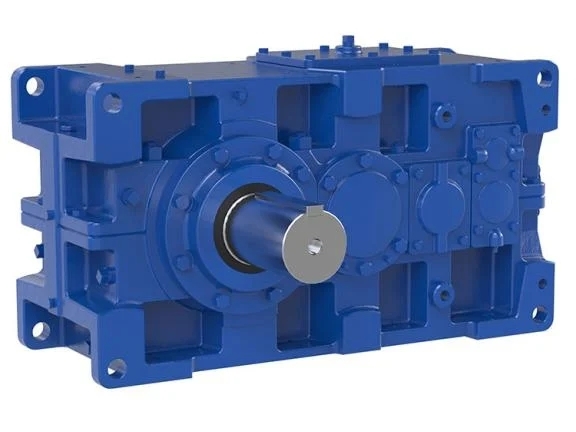

Industrial Gearbox Failure Analysis For Equipment Used By Companies In Amarillo TX

Misalignment of helical gears can have a significant impact on the wear patterns of the gear teeth. When gears are not properly aligned, uneven contact between the teeth can occur, causing increased stress on certain areas and leading to accelerated wear. This can result in specific wear patterns such as uneven tooth wear, pitting, and even tooth breakage if the misalignment is not corrected.

Yes, this particular blog entry discusses legitimate policy issues related to manufacturing, thank you very much.

Posted by on 2024-03-26

Both companies earned 0 out of 150 points in Remake's annual report, which scored 52 leading fashion brands on the progress they've made in key areas. But even brands that scored the highest have a long way to go.

Posted by on 2024-03-18

Tim Cook, in Shanghai to strengthen ties to China's government, told reporters there's "no supply chain in the world more critical to Apple than that of China."

Posted by on 2024-03-21

A moratorium on additional solar import duties expires in June. Cheap solar imports coming into the United States threaten solar panel costs into a tailspin and imperil the continued growth of America’s burgeoning photovoltaic energy sector, a new report forecasts. […]

Posted by on 2024-03-15

Insufficient lubrication is a common cause of specific wear patterns on helical gear teeth. Without proper lubrication, the friction between the gear teeth increases, leading to heat generation and accelerated wear. This can result in wear patterns such as scoring, galling, and surface fatigue, ultimately reducing the lifespan of the gears and affecting their overall performance.

The material composition of helical gears plays a crucial role in determining wear patterns. Gears made from high-quality materials with good wear resistance properties are less likely to experience wear issues compared to gears made from lower-grade materials. Proper material selection can help minimize wear patterns such as pitting, scoring, and abrasive wear, ensuring the longevity and efficiency of the gears.

Overload conditions can significantly impact the wear patterns of helical gear teeth. When gears are subjected to excessive loads beyond their design limits, the contact stress between the teeth increases, leading to accelerated wear and potential damage. This can result in wear patterns such as spalling, cracking, and tooth deformation, indicating the need for adjustments to prevent further wear and ensure the gears' proper functioning.

Abrasive wear in helical gear teeth can be identified by specific wear patterns such as grooving, scratching, and dulling of the tooth surfaces. This type of wear occurs when hard particles or contaminants come into contact with the gear teeth, causing abrasive damage over time. Proper maintenance practices, including regular cleaning and inspection, can help prevent abrasive wear and prolong the lifespan of the gears.

The design of helical gears can influence the occurrence of wear patterns by affecting factors such as tooth profile, contact ratio, and load distribution. A well-designed gear system with proper tooth geometry and alignment can help distribute the load evenly across the gear teeth, reducing the risk of wear and ensuring smooth operation. Additionally, features such as surface treatments, coatings, and lubrication channels can be incorporated into the design to minimize wear patterns and enhance the gears' performance and longevity.

Thermal imaging can be utilized for gearbox failure analysis by detecting abnormal heat patterns that may indicate potential issues such as overheating, friction, or misalignment within the gearbox components. By capturing infrared images of the gearbox during operation, thermal anomalies can be identified and analyzed to pinpoint the root cause of the failure. This non-invasive technique allows for early detection of potential problems, leading to proactive maintenance and preventing costly downtime. Additionally, thermal imaging can provide valuable data for condition monitoring and predictive maintenance strategies, ensuring optimal performance and longevity of the gearbox system. By integrating thermal imaging into gearbox failure analysis, engineers can effectively diagnose and address issues before they escalate, improving overall reliability and efficiency of the equipment.

Gearbox overload conditions can lead to a variety of failure mechanisms, including gear tooth wear, pitting, spalling, and fatigue. When a gearbox is subjected to excessive loads beyond its design limits, the gear teeth can experience increased contact stresses, leading to accelerated wear and surface damage. This can result in the formation of pits, cracks, and ultimately spalling of the gear teeth. Additionally, the repeated cyclic loading from overload conditions can induce fatigue failure in the gearbox components, such as shafts, bearings, and housing. These failure mechanisms can compromise the overall performance and reliability of the gearbox, ultimately leading to costly repairs and downtime. Proper maintenance and monitoring of gearbox loads are essential to prevent these failure mechanisms from occurring.

The surface finish of gear teeth plays a crucial role in determining the wear characteristics of a gearbox. A rough surface finish can lead to increased friction, abrasion, and pitting, resulting in accelerated wear of the gears. Conversely, a smooth surface finish can reduce friction, improve lubrication retention, and enhance load distribution, leading to reduced wear and longer gearbox life. Factors such as surface roughness, waviness, and texture can all impact the performance and durability of gear teeth. Therefore, proper surface finishing techniques, such as grinding, honing, or polishing, are essential in maintaining optimal gearbox performance and minimizing wear. Additionally, the use of advanced coatings or treatments, such as nitriding or carburizing, can further enhance the wear resistance of gear teeth and prolong the lifespan of the gearbox.

The operating temperature of a gearbox plays a crucial role in determining its longevity. High temperatures can accelerate wear and tear on gearbox components, leading to increased friction, thermal expansion, and potential lubrication breakdown. This can result in decreased efficiency, increased maintenance requirements, and ultimately, a shorter lifespan for the gearbox. Conversely, operating the gearbox at lower temperatures can help reduce the risk of overheating and premature failure, allowing for smoother operation and extended longevity. Proper temperature management, through the use of cooling systems or temperature monitoring devices, is essential in maintaining optimal gearbox performance and maximizing its lifespan.

Thermal effects play a significant role in influencing gear tooth contact fatigue in industrial gearboxes. The temperature fluctuations within the gearbox can lead to changes in material properties, such as hardness and strength, which can affect the contact stress distribution on gear teeth. This can result in increased wear, pitting, and spalling of the gear teeth, ultimately leading to premature failure of the gearbox. Additionally, thermal expansion and contraction of the gearbox components can alter the alignment and meshing of the gears, further exacerbating the contact fatigue. Proper lubrication and cooling systems are essential in mitigating these thermal effects and ensuring the longevity and reliability of industrial gearboxes.

Various methods are available for measuring gear tooth surface roughness in failure analysis, including profilometers, interferometers, atomic force microscopes, and scanning electron microscopes. Profilometers are commonly used to measure surface roughness by tracing a stylus along the gear tooth surface and recording the variations in height. Interferometers utilize light waves to measure surface roughness by analyzing interference patterns. Atomic force microscopes provide high-resolution images of the gear tooth surface by scanning a sharp probe over the surface. Scanning electron microscopes use electrons to create detailed images of the gear tooth surface, allowing for precise measurements of roughness. These methods offer valuable insights into the condition of gear teeth and can help identify potential failure mechanisms.