Gearbox seals commonly fail due to lubrication issues such as inadequate lubrication, over-lubrication, or the use of incorrect lubricants. Inadequate lubrication can lead to increased friction and heat generation, causing the seals to wear out quickly. Over-lubrication, on the other hand, can result in excessive pressure on the seals, leading to deformation and eventual failure. The use of incorrect lubricants can also cause degradation of the seal material, reducing its effectiveness over time.

Temperature fluctuations can significantly contribute to the failure of gearbox seals by causing the material to expand and contract. These constant changes in size can put stress on the seals, leading to cracks, leaks, or even complete failure. Extreme temperatures can also cause the seal material to harden or become brittle, making it more susceptible to damage from normal operating conditions. Proper selection of seal materials that can withstand a wide range of temperatures is crucial to prevent premature failure.

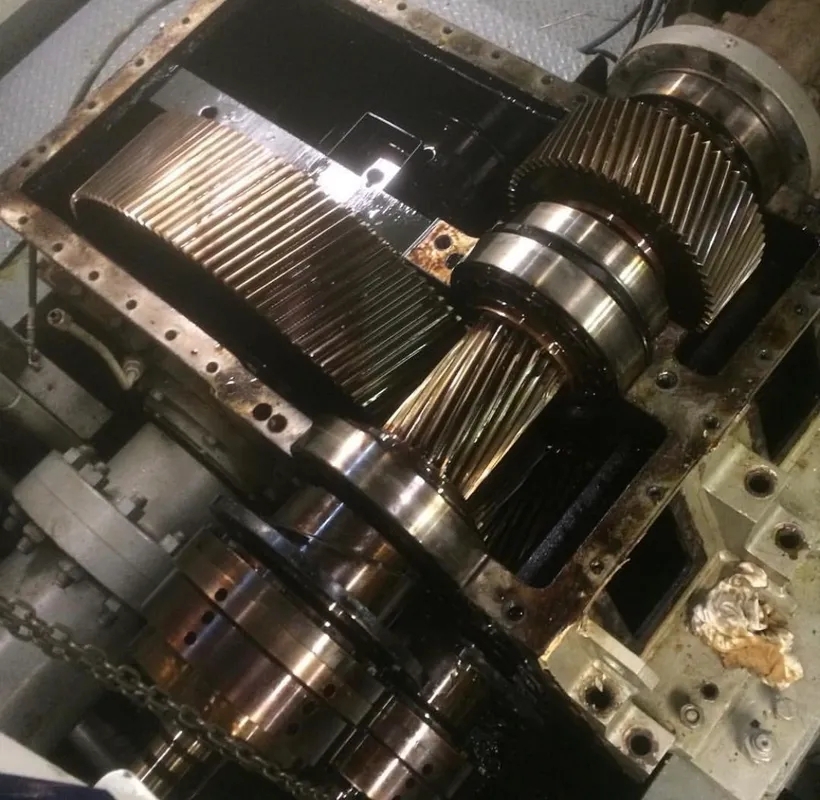

Industrial Gearbox Failure Analysis For Equipment Used By Companies In Amarillo TX

Tim Cook, in Shanghai to strengthen ties to China's government, told reporters there's "no supply chain in the world more critical to Apple than that of China."

Posted by on 2024-03-21

The semiconductor company’s expansion will create nearly 30,000 jobs.

Posted by on 2024-03-20

A bipartisan group of federal lawmakers has introduced the Stop Mexico's Steel Surge Act.

Posted by on 2024-03-19

Both companies earned 0 out of 150 points in Remake's annual report, which scored 52 leading fashion brands on the progress they've made in key areas. But even brands that scored the highest have a long way to go.

Posted by on 2024-03-18

Tennessee’s American Paper Optics makes the solar eclipse glasses used by NASA – and you can get a pair of your own, too.

Posted by on 2024-03-15

Pressure plays a crucial role in causing leaks in gearbox seals. High pressure within the gearbox can push the seals beyond their limits, causing them to deform or break. This can result in oil or grease leaking out of the gearbox, leading to lubrication issues and potential damage to other components. Properly designed seals with the ability to withstand varying levels of pressure are essential to prevent leaks and ensure the efficient operation of the gearbox.

Contaminants such as dirt and debris can have a significant impact on the performance of gearbox seals. When these particles enter the sealing system, they can cause abrasion, wear, and damage to the seal material. This can compromise the integrity of the seal, leading to leaks and reduced effectiveness. Regular maintenance and cleaning of the gearbox and surrounding areas can help prevent the ingress of contaminants and prolong the lifespan of the seals.

Improper installation of gearbox seals can indeed lead to premature failure. If the seals are not installed correctly, they may not be able to effectively prevent leaks or withstand the operating conditions of the gearbox. Common installation errors include incorrect alignment, inadequate sealing surface preparation, or using the wrong tools or techniques. It is essential to follow manufacturer guidelines and best practices when installing gearbox seals to ensure optimal performance and longevity.

Vibration can have detrimental effects on the lifespan of gearbox seals. Excessive vibration can cause the seals to move out of position, leading to misalignment and increased wear. This can result in leaks and reduced sealing efficiency over time. Choosing seals that are specifically designed to withstand vibration and implementing measures to reduce vibration levels within the gearbox can help mitigate the risk of premature seal failure.

The type of material used in gearbox seals can greatly affect their susceptibility to failure. Different materials have varying levels of resistance to heat, pressure, chemicals, and wear. For example, elastomeric seals are commonly used for their flexibility and ability to create a tight seal, but they may not be suitable for high-temperature applications. On the other hand, metal seals are more durable and can withstand higher pressures, but they may be more prone to corrosion. Selecting the right material for the specific operating conditions of the gearbox is crucial in ensuring the longevity and effectiveness of the seals.

Shock loads can have detrimental effects on gearbox components, such as gears, bearings, shafts, and housings. When a gearbox experiences sudden and high impact forces, it can lead to increased wear and tear, premature fatigue, pitting, cracking, and ultimately failure of the components. The sudden force can cause misalignment, increased friction, and stress concentrations, which can result in decreased efficiency and performance of the gearbox. Additionally, shock loads can also lead to increased noise, vibration, and heat generation within the gearbox, further accelerating the degradation of the components. Proper maintenance, lubrication, and design considerations can help mitigate the effects of shock loads on gearbox components.

There are several techniques available for detecting shaft misalignment in industrial gearboxes. Some common methods include laser alignment tools, vibration analysis, thermal imaging, and dial indicators. Laser alignment tools use laser beams to measure the alignment of shafts and can detect misalignment with high precision. Vibration analysis involves monitoring the vibrations of the gearbox to identify any irregular patterns that may indicate misalignment. Thermal imaging can detect temperature variations in the gearbox, which can be a sign of misalignment causing friction. Dial indicators are mechanical devices that measure the runout of shafts to determine if they are misaligned. By utilizing a combination of these techniques, maintenance personnel can effectively detect and correct shaft misalignment issues in industrial gearboxes to prevent further damage and ensure optimal performance.

Reliability analysis methods commonly used for assessing gearbox lubricants include oil analysis, wear particle analysis, and condition monitoring techniques. Oil analysis involves testing the physical and chemical properties of the lubricant to determine its degradation level and contamination levels. Wear particle analysis examines the size, shape, and composition of particles in the lubricant to identify potential gearbox component wear. Condition monitoring techniques, such as vibration analysis and thermography, are used to detect abnormal operating conditions in the gearbox that may affect the lubricant's performance. By utilizing these methods, engineers can assess the reliability of gearbox lubricants and make informed decisions regarding maintenance and replacement schedules.

The effects of gear mesh stiffness on gearbox reliability are significant and multifaceted. A higher gear mesh stiffness can lead to increased transmission efficiency, reduced noise and vibration levels, and improved overall performance of the gearbox. However, excessive gear mesh stiffness can also result in increased wear and tear on the gears, leading to potential failures and decreased reliability over time. It is crucial for engineers to carefully consider the optimal gear mesh stiffness for a gearbox design to ensure a balance between performance and longevity. Factors such as material properties, lubrication, and operating conditions must be taken into account to maximize the reliability of the gearbox. Additionally, regular maintenance and monitoring of gear mesh stiffness can help prevent potential issues and prolong the lifespan of the gearbox.

The material properties of gears play a crucial role in influencing their failure modes. For instance, the hardness, strength, and toughness of the gear material can determine whether failure will occur through mechanisms such as fatigue, wear, or plastic deformation. Gears made from materials with high hardness and strength are less likely to experience wear-related failures, while those with high toughness are more resistant to impact loading. Additionally, the thermal conductivity and coefficient of friction of the gear material can affect failure modes such as overheating and surface damage. Therefore, selecting the appropriate gear material with the right combination of properties is essential in preventing premature failure and ensuring the reliability of the gear system.

The viscosity of oil plays a crucial role in determining gearbox performance and failure rates. When the oil viscosity is too low, it may not provide sufficient lubrication to the gearbox components, leading to increased friction, wear, and heat generation. On the other hand, if the oil viscosity is too high, it can result in poor flow and inadequate lubrication, causing increased resistance and potential damage to the gearbox. Proper oil viscosity ensures optimal lubrication, cooling, and protection of gears, bearings, and other moving parts within the gearbox, ultimately enhancing performance and reducing the likelihood of failure. It is essential to select the correct viscosity grade based on the operating conditions, load, speed, and temperature requirements of the gearbox to ensure efficient operation and longevity.

Vibration signature analysis can aid in detecting gearbox failures by monitoring the unique frequency patterns and amplitude levels associated with normal gearbox operation. By utilizing accelerometers and vibration sensors to collect data on the gearbox's mechanical vibrations, analysts can identify any deviations from the established baseline signatures. Common indicators of gearbox failures include increased levels of harmonics, changes in peak frequencies, and the presence of abnormal patterns such as sidebands or modulation. By analyzing these vibration signatures using advanced signal processing techniques like Fast Fourier Transform (FFT) and spectral analysis, experts can pinpoint potential issues such as gear tooth wear, misalignment, bearing defects, or lubrication problems. This proactive approach allows for early detection of gearbox failures, enabling timely maintenance and preventing costly downtime.