Thermal imaging helps in detecting overheating issues in gearboxes by capturing the infrared radiation emitted by the components. This technology allows for the visualization of temperature variations, making it easier to identify hotspots that could indicate potential problems such as friction, misalignment, or lack of lubrication within the gearbox.

The key benefits of using thermal imaging for gearbox diagnostics include non-invasive inspection, real-time monitoring, and early detection of issues. By utilizing thermal imaging, maintenance teams can quickly assess the condition of gearboxes without the need for disassembly, leading to cost savings and minimizing downtime.

Tim Cook, in Shanghai to strengthen ties to China's government, told reporters there's "no supply chain in the world more critical to Apple than that of China."

Posted by on 2024-03-21

The semiconductor company’s expansion will create nearly 30,000 jobs.

Posted by on 2024-03-20

A bipartisan group of federal lawmakers has introduced the Stop Mexico's Steel Surge Act.

Posted by on 2024-03-19

Both companies earned 0 out of 150 points in Remake's annual report, which scored 52 leading fashion brands on the progress they've made in key areas. But even brands that scored the highest have a long way to go.

Posted by on 2024-03-18

Tennessee’s American Paper Optics makes the solar eclipse glasses used by NASA – and you can get a pair of your own, too.

Posted by on 2024-03-15

Thermal imaging can accurately pinpoint the location of a potential gearbox problem by providing detailed thermal images that highlight temperature anomalies. By analyzing these images, technicians can identify the exact area within the gearbox where overheating is occurring, allowing for targeted repairs or adjustments to be made.

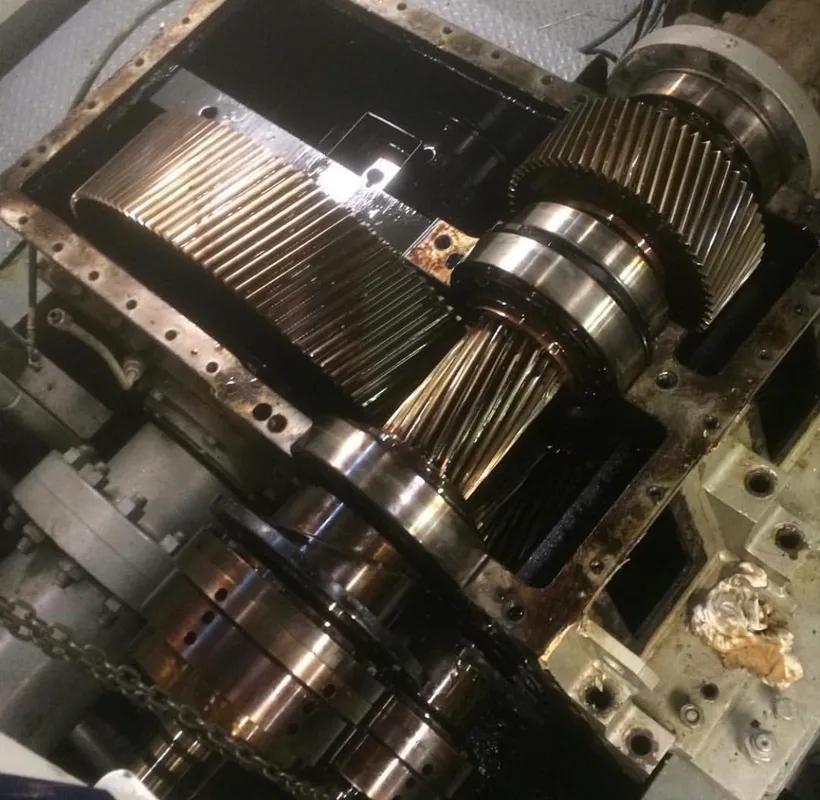

Industrial Gearbox Failure Analysis For Equipment Used By Companies In Amarillo TX

When compared to traditional diagnostic methods for gearboxes, thermal imaging offers several advantages. Traditional methods such as visual inspection or vibration analysis may not always detect early signs of overheating, whereas thermal imaging provides a clear visual representation of temperature variations, making it easier to identify potential issues before they escalate.

Common thermal patterns associated with gearbox malfunctions include localized hotspots, temperature gradients, and uneven heating across components. These patterns can indicate problems such as bearing wear, gear misalignment, or inadequate lubrication, all of which can lead to reduced efficiency and potential breakdowns.

While specific temperature thresholds may vary depending on the type of gearbox and operating conditions, generally, any significant deviation from the normal operating temperature can indicate a gearbox issue when using thermal imaging. Monitoring temperature trends over time can help establish baseline values and identify deviations that may signal a problem.

Thermal imaging data can be used to predict potential future gearbox failures by establishing temperature trends and patterns that indicate wear or stress on components. By regularly monitoring gearbox temperatures and analyzing thermal images, maintenance teams can anticipate potential issues before they escalate, allowing for proactive maintenance and preventing costly breakdowns.

Common signs of helical gear tooth wear in industrial gearbox failure analysis include pitting, spalling, scoring, and micropitting. Pitting is the formation of small craters on the gear tooth surface, while spalling is the breaking off of small pieces of the tooth material. Scoring refers to the presence of scratches or grooves on the gear tooth surface, which can indicate excessive friction and wear. Micropitting is the formation of very small cracks or pits on the gear tooth surface, which can lead to further damage if not addressed. These signs of wear can be indicative of lubrication issues, misalignment, or excessive loads on the gearbox, all of which can contribute to gearbox failure.

To mitigate gearbox resonance issues, several measures can be taken. One approach is to conduct a modal analysis to identify the natural frequencies of the gearbox system. This can help in determining the critical speeds at which resonance may occur. Additionally, implementing proper damping techniques such as adding vibration isolators or tuned mass dampers can help reduce the amplitude of vibrations. Balancing the rotating components of the gearbox and ensuring proper alignment of shafts can also help in minimizing resonance issues. Furthermore, using high-quality materials and precision manufacturing processes can improve the overall stability of the gearbox system. Regular maintenance and monitoring of the gearbox can also help in detecting and addressing any potential resonance issues before they escalate.

Various models are utilized for predicting gearbox bearing failures, including vibration analysis, oil analysis, thermography, and acoustic emission monitoring. These predictive maintenance techniques involve monitoring the condition of bearings by analyzing vibrations, oil samples, temperature changes, and acoustic signals emitted during operation. By using these methods, engineers can detect early signs of bearing wear, lubrication issues, or misalignment, allowing for timely maintenance and preventing unexpected failures. Additionally, machine learning algorithms and artificial intelligence are increasingly being employed to analyze large amounts of data collected from these monitoring techniques to improve the accuracy of predicting gearbox bearing failures. Overall, a combination of these models and technologies can help optimize maintenance schedules, reduce downtime, and extend the lifespan of gearbox bearings.

Gearbox seals can fail due to a variety of reasons, including wear and tear, improper installation, contamination, high temperatures, and excessive pressure. Common failure modes associated with gearbox seals include leaks, cracks, tears, swelling, hardening, and disintegration. These failures can lead to lubricant leakage, loss of efficiency, increased friction, and ultimately, gearbox failure. It is important to regularly inspect and maintain gearbox seals to prevent these failure modes and ensure optimal performance of the gearbox system. Proper selection of materials, correct installation techniques, and adherence to recommended maintenance schedules can help mitigate the risk of seal failures in gearboxes.

The design features of a gearbox can have a significant impact on failure rates. Factors such as material selection, lubrication system efficiency, gear tooth profile, bearing type, and housing design all play a crucial role in determining the reliability and longevity of a gearbox. For example, using high-quality materials with proper heat treatment can improve the strength and wear resistance of gears, reducing the likelihood of premature failure. Similarly, an effective lubrication system can help minimize friction and wear between moving parts, extending the lifespan of the gearbox. Additionally, optimizing the gear tooth profile and selecting the appropriate bearing type can enhance load distribution and reduce stress concentrations, further decreasing the risk of failure. Overall, incorporating robust design features in a gearbox can help mitigate potential failure modes and improve overall performance and reliability.

Lubricant additives play a crucial role in influencing gearbox performance and longevity by enhancing the overall lubrication properties of the oil. These additives, such as anti-wear agents, friction modifiers, and corrosion inhibitors, help reduce friction between moving parts, prevent metal-to-metal contact, and protect against rust and oxidation. By improving the lubricity and film strength of the oil, additives can minimize wear and tear on gears, bearings, and other components, leading to smoother operation and extended lifespan of the gearbox. Additionally, certain additives like viscosity index improvers can help maintain optimal oil viscosity over a wide range of temperatures, ensuring consistent performance in varying operating conditions. Overall, the right combination of lubricant additives can significantly improve gearbox efficiency, reliability, and durability.