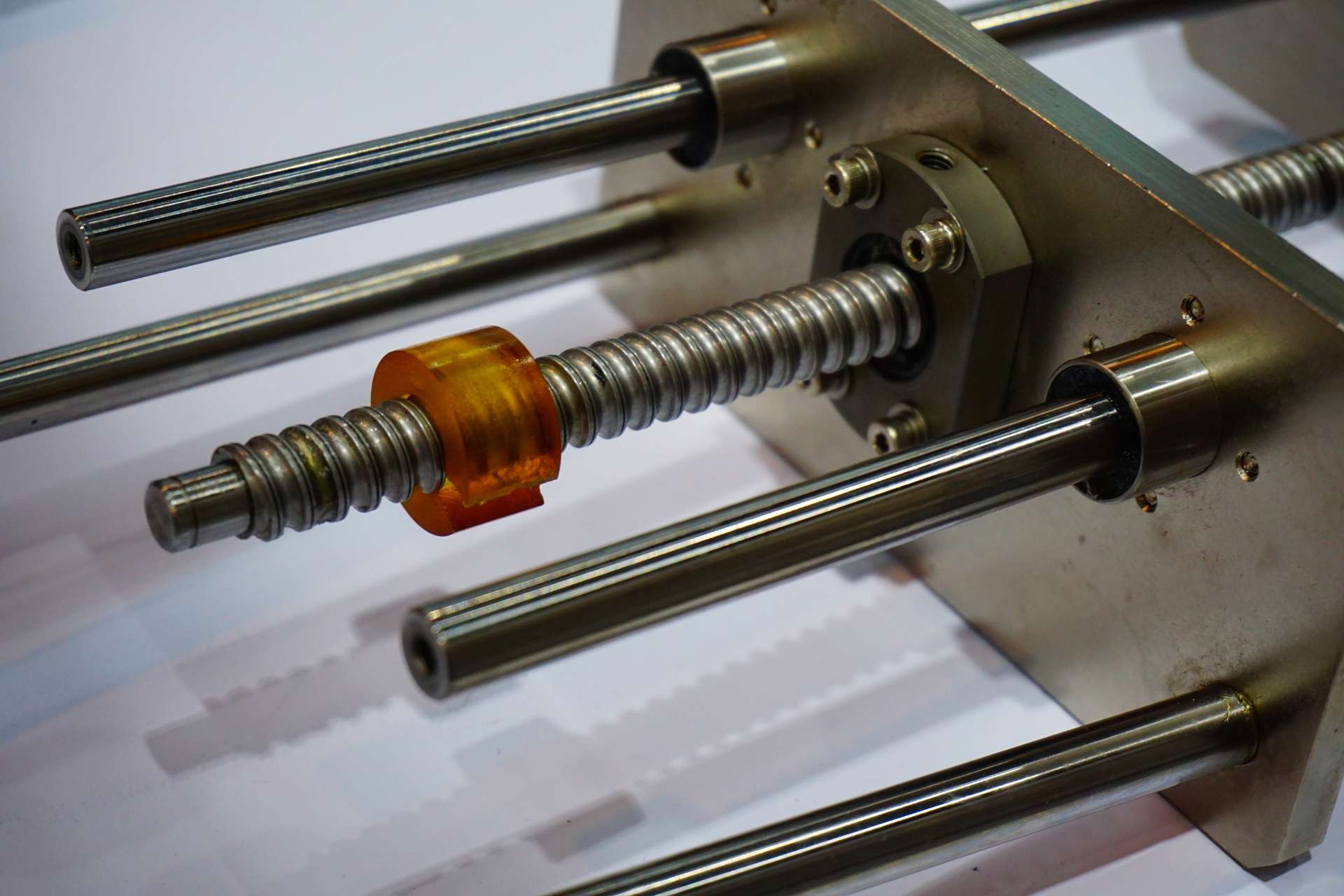

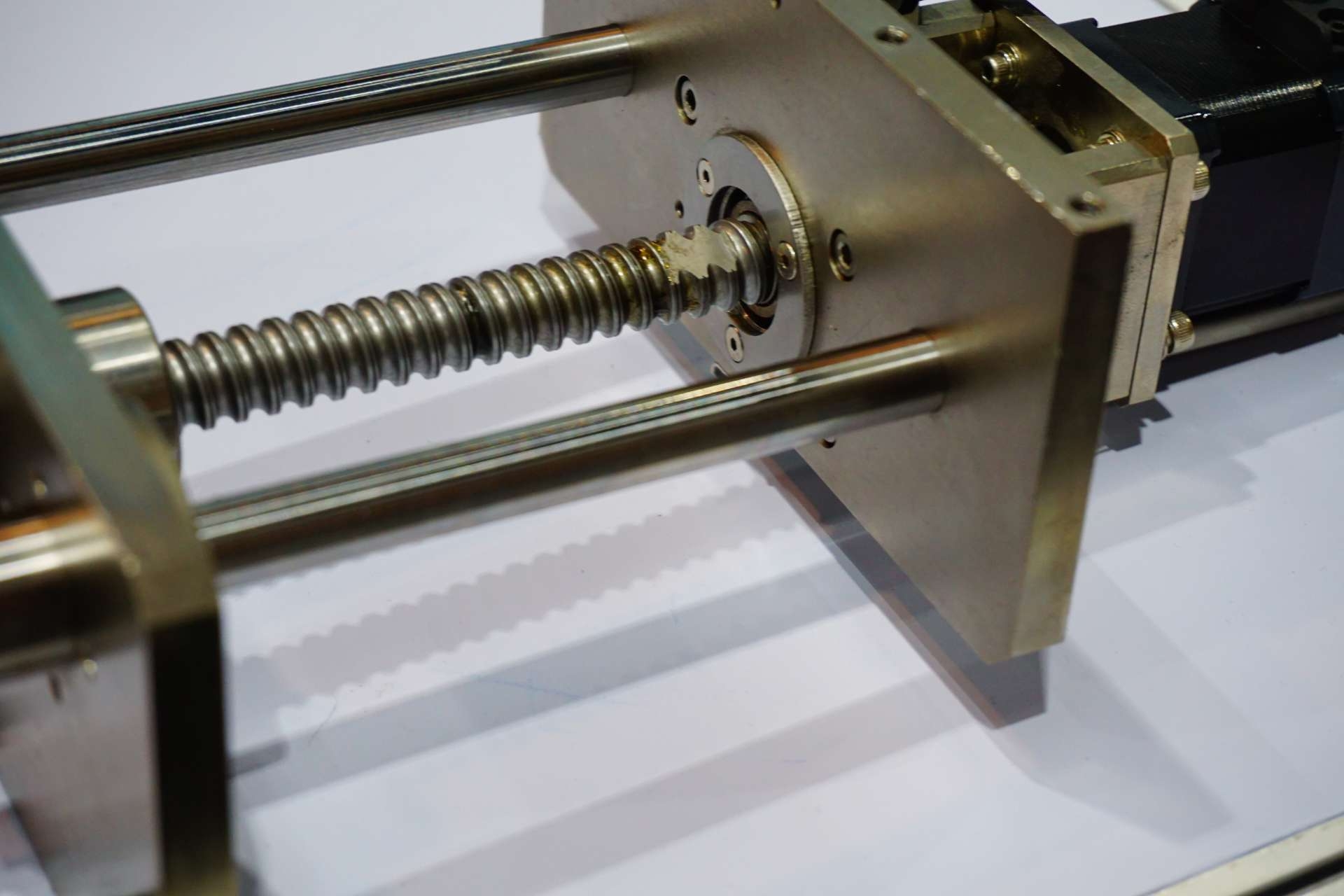

Thermal Expansion of Ball Screws

How does the coefficient of thermal expansion affect the performance of ball screws?

The coefficient of thermal expansion plays a crucial role in the performance of ball screws. As the temperature changes, the ball screw material expands or contracts, affecting its dimensions. This can lead to issues such as increased friction, reduced accuracy, and even structural damage if not properly accounted for in the design and material selection.