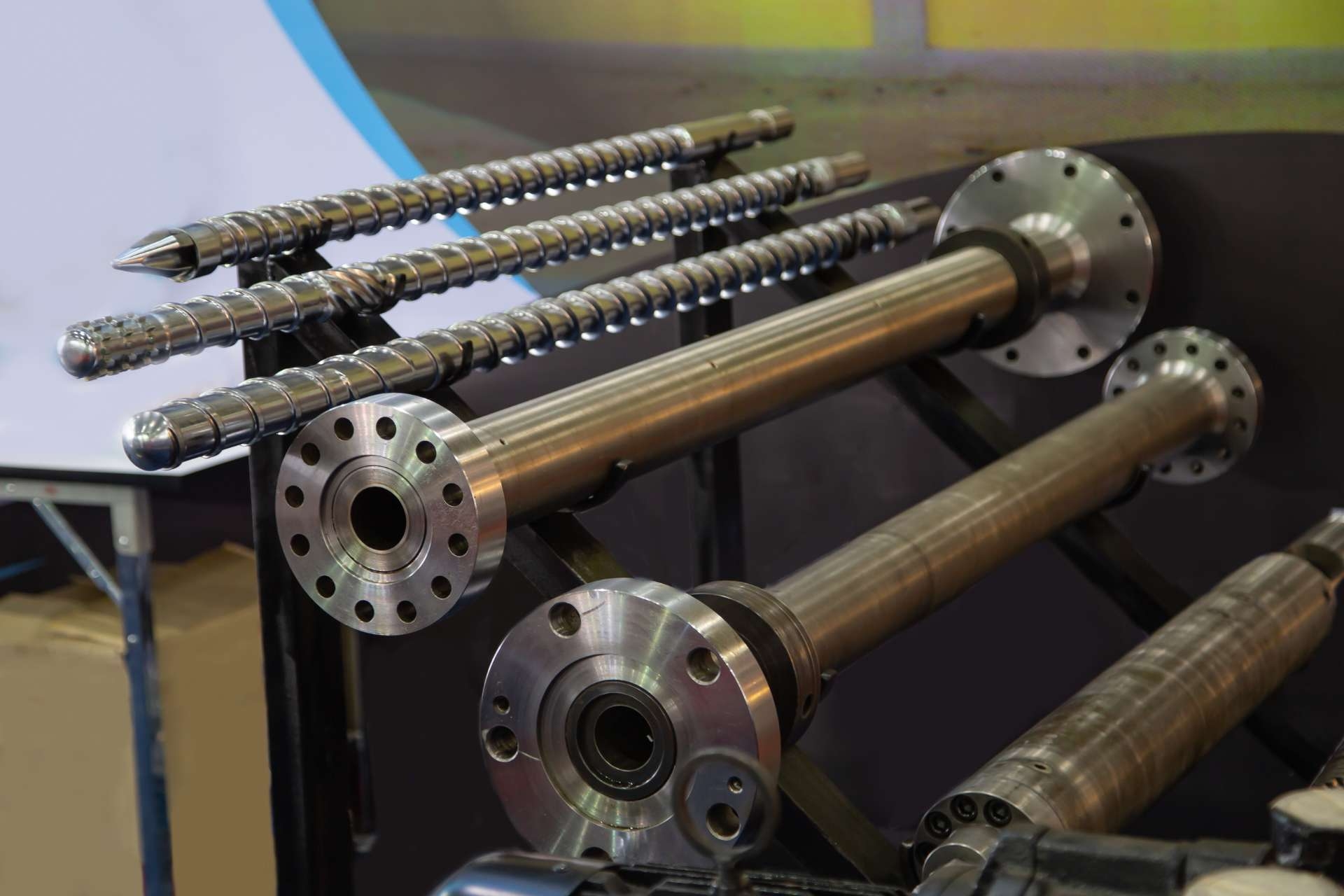

Industrial Ball Screw Wear Analysis and How It Works

How does wear analysis of industrial ball screws help in predicting maintenance needs?

Wear analysis of industrial ball screws plays a crucial role in predicting maintenance needs by providing valuable insights into the condition of the components. By monitoring the wear patterns and levels of ball screws, maintenance teams can anticipate potential issues before they escalate into costly breakdowns. This proactive approach allows for timely maintenance interventions, reducing downtime and extending the lifespan of the equipment.

Understanding the wear analysis of industrial ball screws is essential for maintaining the efficiency and longevity of machinery. Regular wear analysis can help identify potential issues before they lead to significant downtime. To learn more about Industrial Ball Screw Wear Analysis and How It Works, visit: https://www.screwandbarrelrepair.com/services/ball-screw-repair. Performing routine wear analysis can extend the life of ball screws and improve overall machine performance.