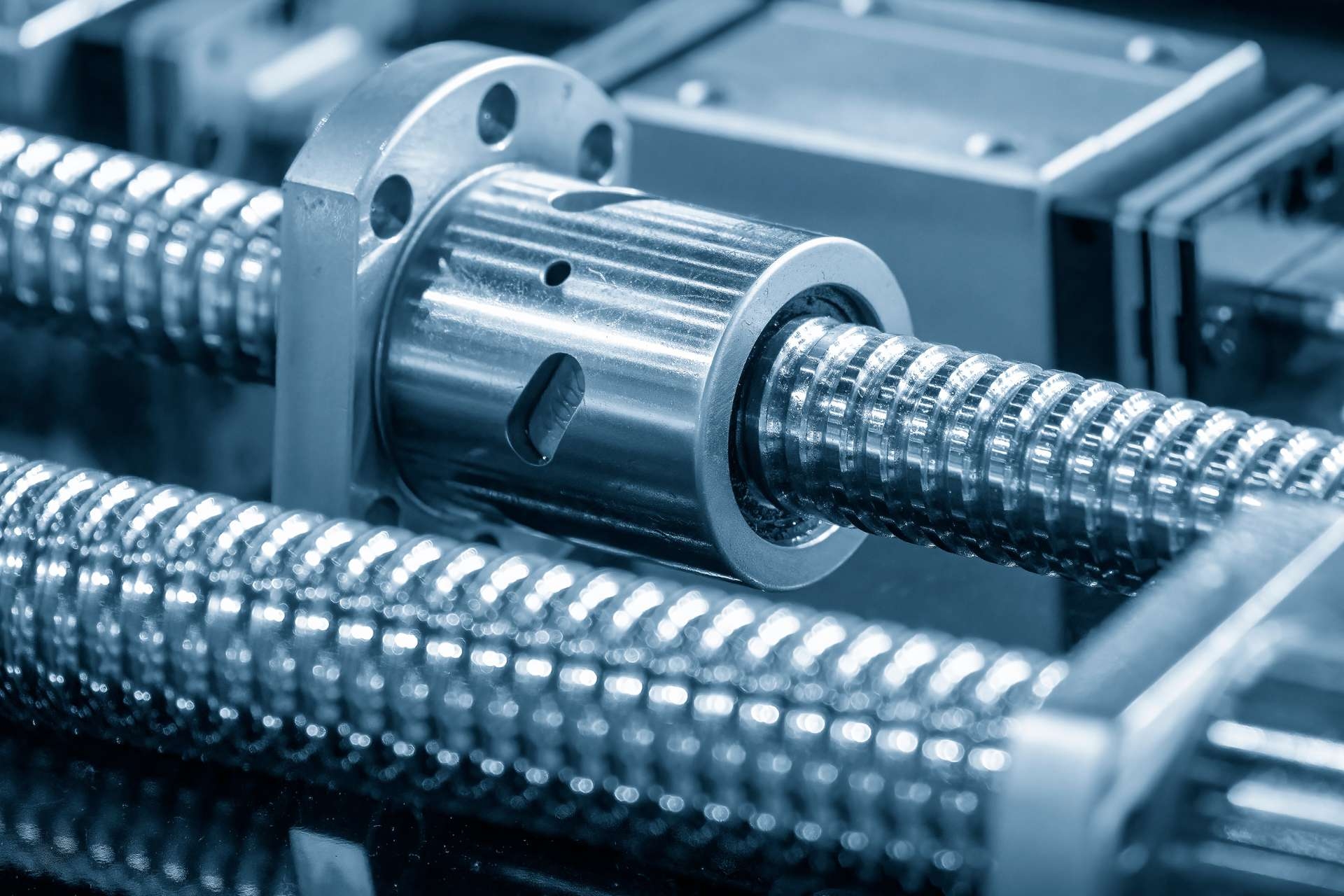

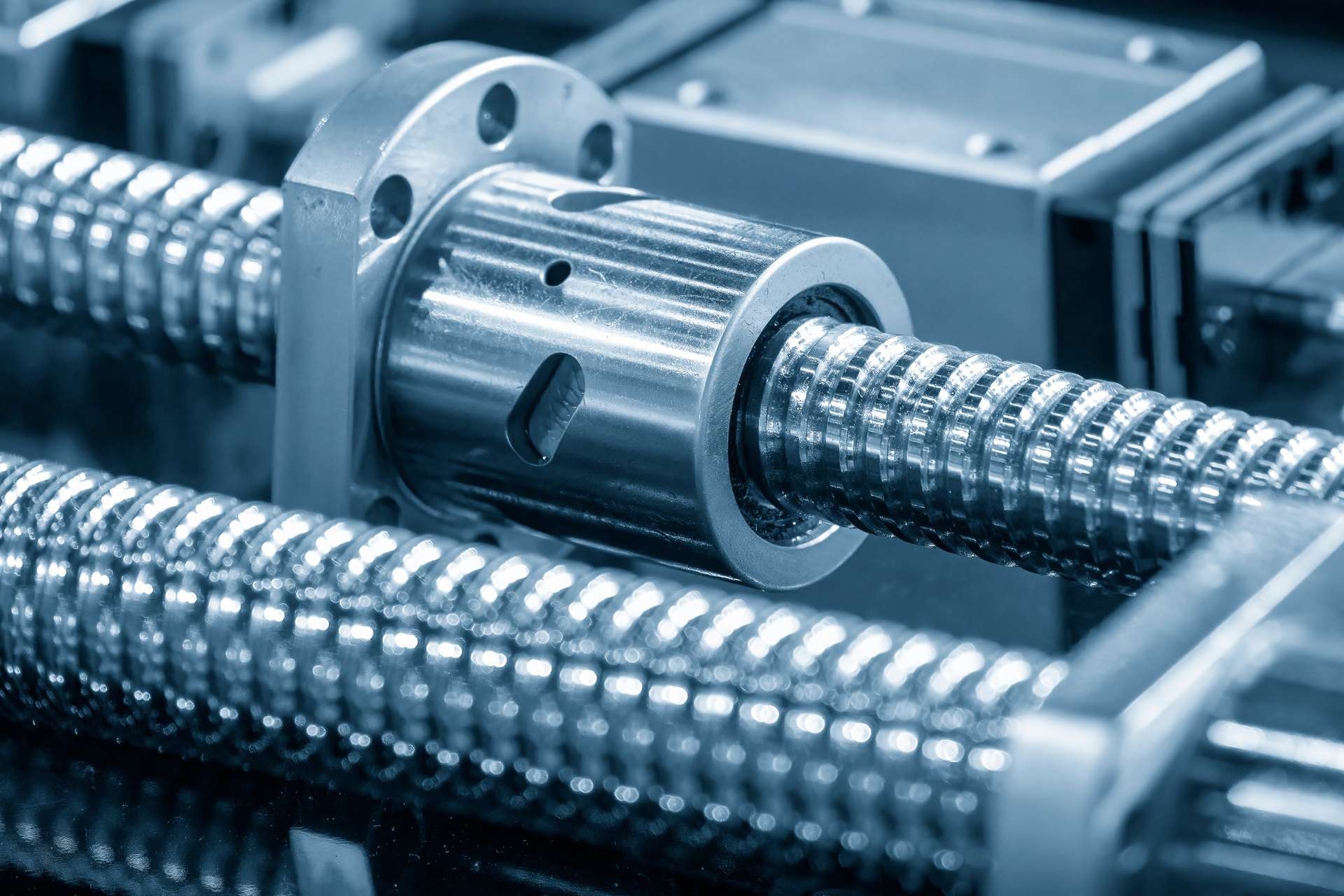

Ball Recirculation Systems

How do ball recirculation systems improve the efficiency of ball screw assemblies?

Ball recirculation systems improve the efficiency of ball screw assemblies by continuously circulating the balls within the system, reducing friction and wear on the components. This allows for smoother and more precise movement, resulting in higher accuracy and repeatability in machinery operations. The recirculation of the balls also helps distribute the load evenly, increasing the overall lifespan of the ball screw assembly.