SMD (Surface-Mount Device) LEDs

How do SMD LEDs differ from traditional through-hole LEDs in terms of size and installation?

Surface-mount device (SMD) LEDs differ from traditional through-hole LEDs primarily in size and installation method. SMD LEDs are much smaller and are designed to be mounted directly onto the surface of a printed circuit board (PCB) using soldering techniques. This allows for a more compact and streamlined design compared to through-hole LEDs, which require holes to be drilled in the PCB for installation.

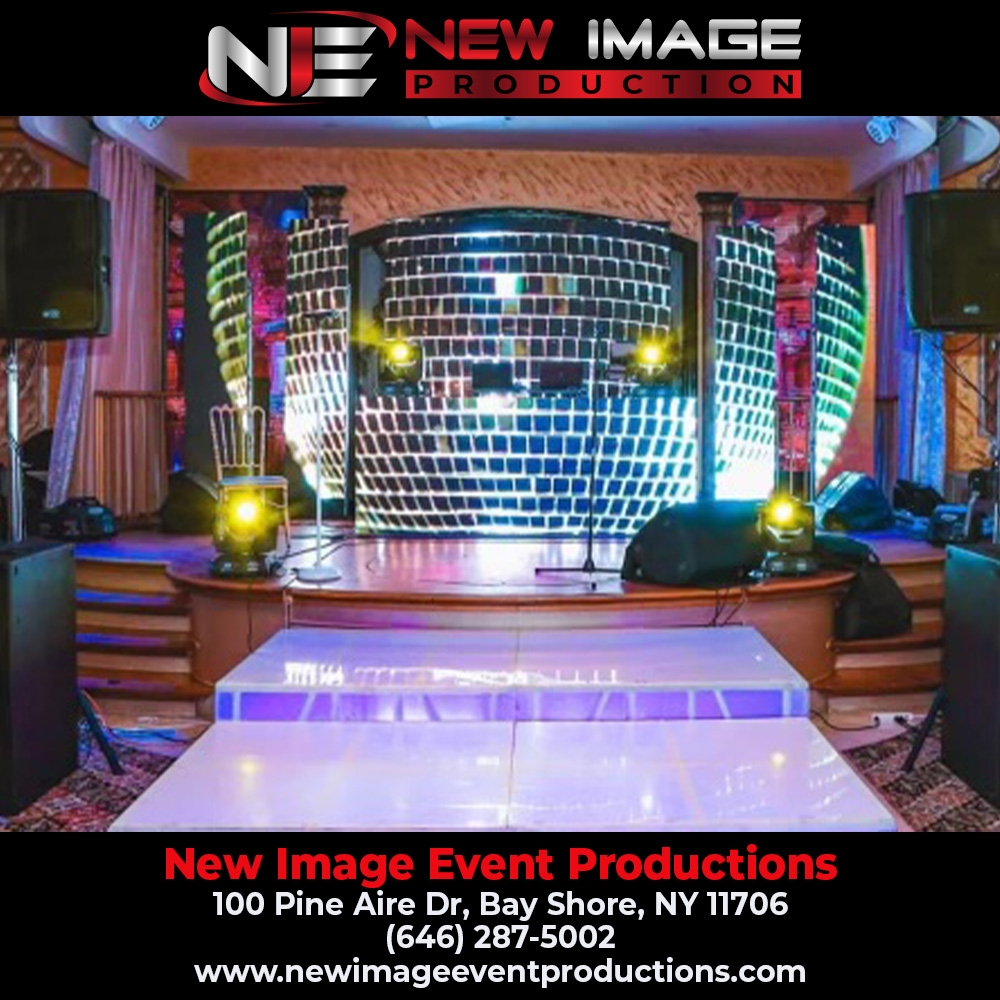

How Pixel Pitch Affects Image Quality in LED Video Walls